Ƙarshen Surface don CNC Machining

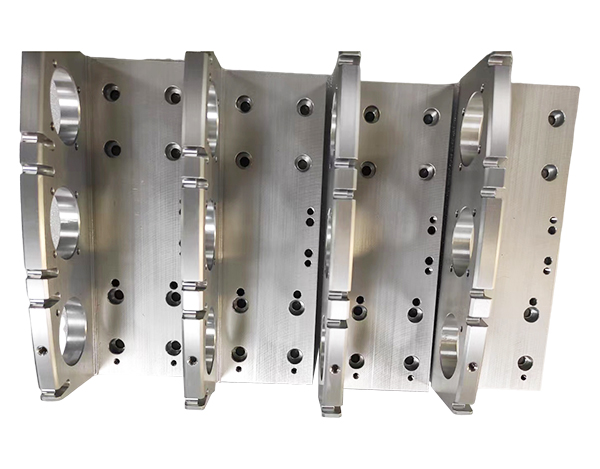

Ƙarshen saman wani tsari ne wanda ke taimakawa ayyana da kuma daidaita rubutun gaba ɗaya bayan aikin CNC.

A Kachi, muna da inganci kuma muna shirye don keɓance sassa don abubuwan amfani daban-daban.Ko kana manne wa m girma tolerances da santsi gama ko bukatar ƙarin lalata da lalacewa juriya, mu surface gama ga CNC machining iya samar da abin da kuke bukata.

Menene Machining Surface Finish?

Ƙarshen saman ya ƙunshi tsarin canza yanayin ƙarfe ta hanyar sake fasalin, cirewa ko ƙarawa, kuma ana amfani da shi don auna yanayin yanayin da ke da:

Kwanciya- Jagoran ƙirar shimfidar wuri mai mahimmanci (sau da yawa ana ƙaddara ta hanyar masana'anta).

Wawanci- Yana da alaƙa da ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙa'idodi, kamar filaye waɗanda aka karkace ko kuma aka karkata daga ƙayyadaddun bayanai.

Tashin Lafiya- Ma'auni na rashin daidaituwar sararin samaniya.Gabaɗaya, rashin ƙarfi na saman shine abin da masana injiniyoyi ke nufi da “ƙarewa saman” yayin da amfani da “nauyin saman” ya zama ruwan dare yayin da ya shafi duk halaye uku.

Wadanne nau'ikan abubuwan da za a yi la'akari da su yayin zabar gamawar mashin ɗin CNC?

Aikace-aikace na samfurin

Abubuwan muhalli daban-daban, kamar girgiza, zafi, danshi, UV radiation, da sauransu, ana amfani da su zuwa sassa daban-daban na CNC.Kuna iya zaɓar da hikima idan kun yi la'akari da hankali ga wane da abin da samfurin yake.

Dorewa

Yaya tsawon lokacin da kuke son samfurin ku ya ɗora shine tambaya dole ne ku yi wa kanku.Ƙirƙira ya ƙunshi ɗorewa da yawa.Kayan albarkatun kasa yana da mahimmanci a wannan yanayin, amma dole ne ku yi la'akari da machining surface goge.Dorewa abu ne na haɓaka ƙimar samfuran da aka gama.Don haka, ya kamata ku zaɓi ƙarewar da ta dace.

Girman sashi

Yana da mahimmanci a tuna cewa gama aikin injin na iya canza girman wani yanki.Ƙaƙƙarfan ƙarewa kamar murfin foda na iya ƙara kauri daga saman abin ƙarfe.

Amfanin Ƙarfe Tsarin Kammala Tsarin Mulki

Ana iya taƙaita ayyukan jiyya na saman ƙarfe kamar haka:

● Inganta bayyanar

● Ƙara takamaiman launuka masu kyau

● Canja haske

● Haɓaka juriya na sinadarai

● Ƙara juriya

● Iyakance illar lalata

● Rage gogayya

● Cire lahani

● Tsaftace sassan

● Yi hidima azaman rigar fari

● Daidaita masu girma dabam

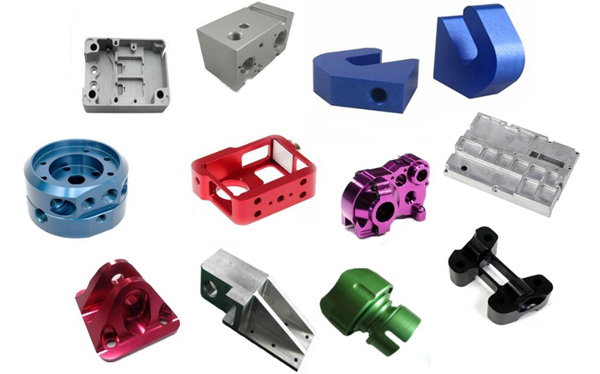

A Kachi, Ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrunmu za su ba da shawara game da ingantaccen jiyya da dabarun gamawa don cimma sakamakon da kuke so.Za ku iya zaɓar mafi kyawun gamawa wanda ke ƙarfafawa da kare bayyanar sassan injin.Hanyoyin jiyya da ke akwai sun haɗa da kamar haka:

Anodize

Anodize shine tsarin wucewa na electrolytic wanda ke tsiro Layer oxide na halitta akan sassan aluminum don kariya daga lalacewa da lalata, da kuma tasirin kwaskwarima.

Ƙwaƙwalwar Ƙwaƙwalwa

Harshen watsa labarai yana amfani da jet mai matsi na kafofin watsa labarai mai ɓarna don amfani da matte, gamawa iri ɗaya zuwa saman sassa.

Electroplating

Nickel plating wani tsari ne da ake amfani da shi don sanya ɗan ƙaramin nickel ɗin lantarki zuwa wani ɓangaren ƙarfe.Ana iya amfani da wannan plating don lalata da juriya, da kuma dalilai na ado.

goge baki

Kayan aikin CNC na al'ada ana goge su da hannu a cikin kwatance da yawa.Fuskar yana da santsi kuma dan kadan ne.

Chromate

Jiyya na chromate suna amfani da fili na chromium zuwa saman ƙarfe, yana baiwa ƙarfen ƙarewar lalacewa.Wannan nau'in ƙarewar saman yana kuma iya ba da ƙarfen siffar ado, kuma yana da tasiri mai tasiri ga nau'ikan fenti.Ba wai kawai ba, har ma yana ba da damar ƙarfe don kiyaye ƙarfin wutar lantarki.

Zane

Zane ya ƙunshi fentin fenti a saman ɓangaren.Za a iya daidaita launuka zuwa lambar launi na Pantone na zaɓin abokin ciniki, yayin da ƙarewar kewayo daga matte zuwa mai sheki zuwa ƙarfe.

Black Oxide

Black oxide shafi ne na juyawa mai kama da Alodine wanda ake amfani da shi don karfe da bakin karfe.Ana amfani dashi musamman don bayyanar da juriya mai laushi.

Alamar sashi

Alamar sashe hanya ce mai tsada don ƙara tambura ko wasiƙa na al'ada zuwa ƙirar ku kuma galibi ana amfani da ita don alamar sashe na al'ada yayin samar da cikakken sikelin.

| Abu | Akwai Ya Ƙare Ƙarshen Sama | Aiki | Bayyanar Rufi | Kauri | Daidaitawa | Dace Material |

| 1 | Share Anodize | Rigakafin oxidation, anti-gogayya, yi ado adadi | Bayyananne, Black, Blue, Green, Zinare, Ja | 20-30 μm | ISO7599, ISO8078, ISO8079 | Aluminum da kayan aiki |

| 2 | Hard Anodize | Anti-oxidizing, Anti-stacic, ƙara abrasion juriya da taurin saman, ado | Baki | 30-40 m | ISO10074, BS/DIN 2536 | Aluminum da kayan aiki |

| 3 | Allodine | Ƙara juriya na lalata, haɓaka tsarin farfajiya da tsabta | Bayyananne, mara launi, launin rawaya, launin ruwan kasa, launin toka, ko shuɗi | 0.25-1.0 μm | Mil-DTL-5541, MIL-DTL-81706, ƙa'idodin Mil-spec | Karfe daban-daban |

| 4 | Chrome Plating / Hard Chrome Plating | Juriya na lalata, haɓaka taurin ƙasa da juriya abrasion, Anti=tsatsa, ado | Zinariya, Azurfa mai haske | 1-1.5m Saukewa: 8-12μm | Ƙididdigar SAE-AME-QQ-C-320, Class 2E | Aluminum da kayan aiki Karfe da kayan sa |

| 5 | Nickel Plating mara amfani | Ado, rigakafin tsatsa, haɓaka taurin, juriya na lalata | Mai haske, rawaya mai haske | 3-5 m | MIL-C-26074, ASTM8733 da AMS2404 | Daban-daban Karfe, Karfe da Aluminum gami |

| 6 | Zinc Plating | Anti-tsatsa, kayan ado, haɓaka juriya na lalata | Blue, fari, ja, rawaya, baki | 8-12 m | ISO/TR 20491, ASTM B695 | Karfe iri-iri |

| 7 | Plating Zinariya / Azurfa | Eletric da electromagnetic igiyar ruwa conduction, ado | Golder, Azurfa mai haske | Zinariya: 0.8-1.2μm Azurfa: 7-12μm | MIL-G-45204, ASTM B488, AMS 2422 | Karfe da kayan sa |

| 8 | Black Oxide | Anti-tsatsa, kayan ado | Baƙar fata, Baƙar fata | 0.5-1 m | ISO11408, MIL-DTL-13924, AMS2485 | Bakin Karfe, Karfe Chromium |

| 9 | Foda Paint /Painting | juriya na lalata, kayan ado | Baƙar fata ko kowace Ral code ko lambar Pantone | 2-72m | Matsayin kamfani daban-daban | Karfe iri-iri |

| 10 | Passivation na Bakin Karfe | Anti-tsatsa, kayan ado | Babu faɗakarwa | 0.3-0.6 m | ASTM A967, AMS2700&QQ-P-35 | Bakin Karfe |

Maganin Zafi

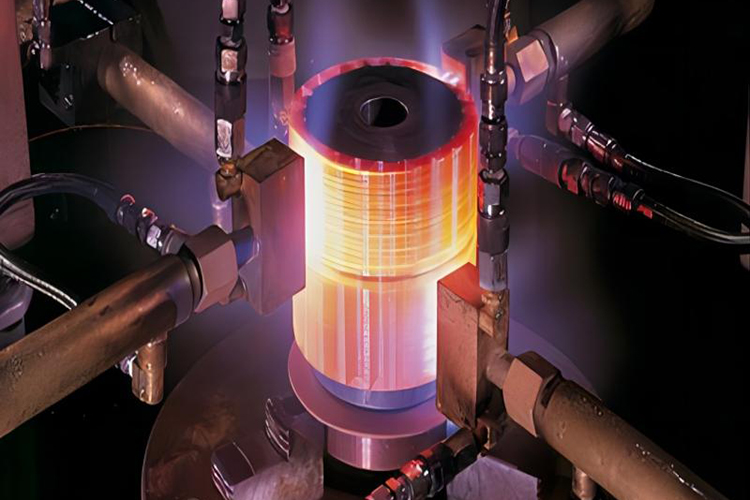

Maganin zafi muhimmin mataki ne a cikin ingantattun injina.Duk da haka, akwai fiye da hanya ɗaya don cika shi, kuma zaɓinku na maganin zafi ya dogara da kayan aiki, masana'antu da aikace-aikace na ƙarshe.

Ayyukan Maganin Zafi

Maganin zafi mai zafi shine tsarin da ƙarfe ke yin zafi ko sanyaya a cikin yanayi mai ƙarfi don sarrafa kaddarorin jiki kamar rashin ƙarfi, karko, ƙirƙira, tauri, da ƙarfi.Ƙarfe-ƙarfa masu zafi suna da mahimmanci ga masana'antu da yawa waɗanda suka haɗa da sararin samaniya, motoci, kwamfuta, da masana'antar kayan aiki masu nauyi.Zafi na maganin sassa na ƙarfe (kamar sukurori ko madaidaicin injin) yana haifar da ƙima ta haɓaka haɓakarsu da aiki.

Maganin zafi tsari ne mai matakai uku.Na farko, ana ƙona ƙarfe zuwa takamaiman zafin jiki da ake buƙata don kawo canjin da ake so.Na gaba, ana kiyaye zafin jiki har sai karfe ya yi zafi sosai.Ana cire tushen zafi, yana barin ƙarfe ya yi sanyi gaba ɗaya.

Karfe shine karfen da aka fi yi da zafi amma ana yin wannan tsari akan wasu kayan:

● Aluminum

● Tagulla

● Tagulla

● Zuba Ƙarfe

● Tagulla

● Hastelloy

● Inconel

● Nickel

● Filastik

● Bakin Karfe

Zaɓuɓɓukan Maganin Zafi Daban-daban

Ƙarfafawa:Ana yin tauraro don magance ƙarancin ƙarfe, musamman waɗanda ke shafar tsayin daka gabaɗaya.Ana yin shi ta hanyar dumama karfe da kuma kashe shi da sauri daidai lokacin da ya kai ga abubuwan da ake so.Wannan yana daskare barbashi don haka ya sami sabbin halaye.

Ƙarfafawa:Ana yin tauraro don magance ƙarancin ƙarfe, musamman waɗanda ke shafar tsayin daka gabaɗaya.Ana yin shi ta hanyar dumama karfe da kuma kashe shi da sauri daidai lokacin da ya kai ga abubuwan da ake so.Wannan yana daskare barbashi don haka ya sami sabbin halaye.

Annealing:Mafi yawanci tare da aluminum, jan karfe, karfe, azurfa ko tagulla, annealing ya haɗa da dumama karfe zuwa babban zafin jiki, riƙe shi a can kuma yana ba shi damar yin sanyi a hankali.Wannan yana sa waɗannan karafa su sami sauƙin aiki zuwa siffa.Copper, Azurfa da tagulla za a iya sanyaya su cikin sauri ko a hankali, dangane da aikace-aikacen, amma karfe dole ne ya yi sanyi a hankali ko kuma ba zai gushewa yadda ya kamata ba.Ana yin wannan yawanci kafin mashin ɗin don kada kayan su gaza yayin kera.

Daidaitawa:Sau da yawa ana amfani da shi akan karfe, daidaitawa yana inganta machinability, ductility da ƙarfi.Karfe yana zafi zuwa digiri 150 zuwa 200 ya fi zafi fiye da karafa da ake amfani da su wajen kawar da su kuma ana gudanar da shi a can har sai canjin da ake so ya faru.Tsarin yana buƙatar ƙarfe don yin sanyi don ƙirƙirar hatsi mai ladabi.Wannan kuma yana da amfani don cire hatsi na columnar da rarrabuwar dendritic, wanda zai iya daidaita inganci yayin jefa wani sashi.

Haushi:Ana amfani da wannan tsari don kayan haɗin ƙarfe na ƙarfe, musamman ƙarfe.Waɗannan allunan suna da matuƙar wuya, amma galibi suna da ƙarfi don manufarsu.Tempering yana zafi karfe zuwa zafin jiki kusa da mahimmin batu, saboda wannan zai rage raguwa ba tare da lalata taurin ba.Idan abokin ciniki yana son samun mafi kyawun filastik tare da ƙarancin tauri da ƙarfi, muna dumama ƙarfe zuwa zafin jiki mafi girma.Wani lokaci, ko da yake, kayan suna da juriya ga zafin rai, kuma yana iya zama da sauƙi don siyan kayan da aka rigaya ya taurare ko a taurare shi kafin yin injin.

Harka taurin: Idan kuna buƙatar ƙasa mai ƙarfi amma mai laushi mai laushi, taurin hali shine mafi kyawun fare ku.Wannan tsari ne na gama gari don karafa tare da ƙarancin carbon, kamar ƙarfe da ƙarfe.A cikin wannan hanyar, maganin zafi yana ƙara carbon zuwa saman.Kullum za ku yi odar wannan sabis ɗin bayan an ƙera guntuwa don ku sa su zama masu dorewa.Ana yin ta ne ta hanyar amfani da zafi mai zafi tare da wasu sinadarai, saboda hakan yana rage haɗarin yin ɓangaren da ya lalace.

Tsufa:Har ila yau, an san shi da hardening hazo, wannan tsari yana ƙara yawan ƙarfin ƙarfe masu laushi.Idan karfe yana buƙatar ƙarin taurin fiye da tsarin sa na yanzu, taurin hazo yana ƙara ƙazanta don ƙara ƙarfi.Wannan tsari yawanci yana faruwa ne bayan an yi amfani da wasu hanyoyin, kuma yana ɗaga yanayin zafi kawai zuwa matakan tsakiya kuma yana sanyaya abu cikin sauri.Idan mai fasaha ya yanke shawarar tsufa na halitta shine mafi kyau, ana adana kayan a cikin yanayin sanyi har sai sun isa abubuwan da ake so.