Surface Inopedzisa yeCNC Machining

Kupedzwa kwepamusoro inzira inobatsira kutsanangura uye kunatsiridza magadzirirwo ese mushure meCNC machining.

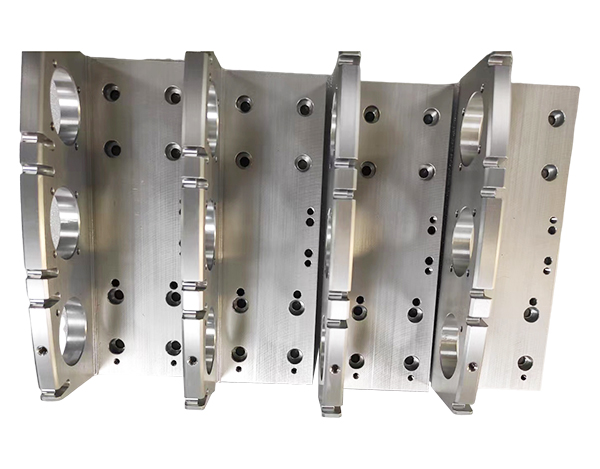

PaKachi, isu tiri mhando inofambiswa uye takagadzirira kugadzirisa zvikamu zvekushandisa kwakasiyana.Kunyangwe iwe uri kuomerera kune yakasimba dimensional kushivirira uye yakatsetseka kupera kana kuti inoda yakawedzera ngura uye kupfeka kuramba, yedu yepamusoro inopera yeCNC machining inogona kuburitsa zvaunoda.

Chii chinonzi Machining Surface Finish?

Kupedzisa kwepamusoro kunosanganisira maitiro ekushandura simbi yepasi kuburikidza nekugadzirisa patsva, kubvisa kana kuwedzera, uye inoshandiswa kuyera kuumbwa kwese kwepasi kunoratidzwa ne:

Lay-Nhungamiro yemhando yepamusoro yepamusoro (kazhinji inotsanangurwa nemaitiro ekugadzira).

Waviness-Inoenderana nekusakwana kana kusakwana kwakakomba, senge nzvimbo dzakatenderedzwa kana kutsauka kubva pane zvakatemwa.

Kukasharara Kwepamusoro- Chiyero chekusagadzikana kwepasi kwakatsetseka.Kazhinji, kushata kwepamusoro ndiko kunonzi nemachinists se "kupedzisa kwepamusoro" ukuwo kushandiswa kwe "chiso chepamusoro" kwakajairika kana zvine chekuita nehunhu hutatu.

Ndeapi marudzi ezvinhu zvekufunga kana uchisarudza CNC machining pamusoro pekupedzisira?

Zvishandiso zvechigadzirwa

Zvakasiyana zvezvakatipoteredza zvinhu, senge vibrations, kupisa, hunyoro, UV mwaranzi, nezvimwe, zvinoiswa kune akasiyana CNC makina zvikamu.Unogona kusarudza zvine hungwaru kana ukanyatsofunga kuti chigadzirwa chacho ndecheani uye chii.

Kugara kwenguva refu

Kuti unoda kuti chigadzirwa chako chigare kwenguva yakareba sei mubvunzo waunofanira kuzvibvunza.Kugadzira kunosanganisira zvakawanda zvekugara kwenguva refu.Iyo yakasvibirira yakakosha mune iyi kesi, asi iwe unofanirwawo kufunga nezve machining pamusoro pePolish.Durability chinhu mukusimudzira kukosha kwechigadzirwa chako chapera.Naizvozvo, iwe unofanirwa kusarudza iyo yakakodzera kupera.

Zviyero zvechikamu

Izvo zvakakosha kuti uyeuke kuti machining pamusoro pekupedzisira anogona kushandura zviyero zvechikamu.Mapedzi akakora sehupfu anogona kuwedzera ukobvu hwepamusoro hwechinhu chesimbi.

Iyo mukana weMetal Surface Finishing process

Mabasa esimbi pamusoro pekurapa anogona kupfupikiswa sezvizvi:

● Vandudza chitarisiko

● Wedzera mavara chaiwo akaisvonaka

● Shandura kupenya

● Kuwedzera kusagadzikana kwemakemikari

● Wedzera kusakara

● Gadzirisa migumisiro yekuora

● Deredza kukandirana

● Bvisa zvirema

● Kuchenesa mativi

● Shandira sejasi rekutanga

● Chinja saizi

KuKachi, Chikwata chedu chehunyanzvi chenyanzvi chinopa zano pamusoro peakakodzera epamusoro marapirwo uye kupedzisa matekiniki kuti uwane zvaunoshuvira zvaurikuda.Unogona kusarudza yakanakisa kupedzisa inosimbisa uye inodzivirira kutaridzika kwezvikamu zvemuchina.Iwo aripo epamusoro pekurapa maitiro anosanganisira seanotevera:

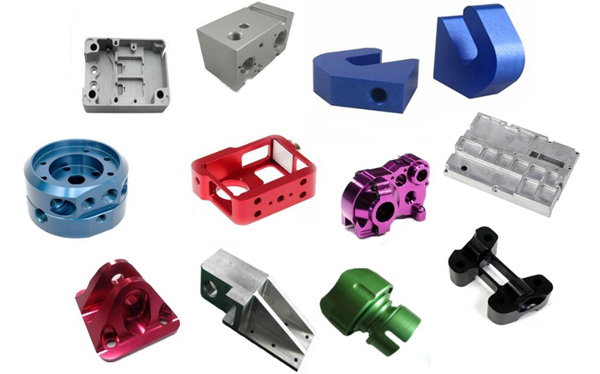

Anodize

Anodize ndeye electrolytic passivation process inokura iyo yakasikwa oxide layer pane aruminiyamu zvikamu zvekudzivirira kubva pakupfeka nekuora, pamwe neyekuzora maitiro.

Bead Blasting

Media blasting inoshandisa jeti yakamanikidzwa yeabrasive media kuisa matte, yunifomu kupera pamusoro pezvikamu.

Electroplating

Nickel plating inzira inoshandiswa kuita electroplate chidimbu chitete chenickel pachikamu chesimbi.Iyi plating inogona kushandiswa kuita ngura uye kupfeka kuramba, pamwe nekushongedza.

Kupukuta

Tsika CNC machining zvikamu zvakakwenenzverwa nemaoko munzira dzakawanda.Nzvimbo yacho inotsvedzerera uye inoratidzira zvishoma.

Chromate

Mishonga yeChromate inoshandisa chromium musanganiswa kune pamusoro pesimbi, ichipa simbi kupedzwa isingaite ngura.Rudzi urwu rwekupedzisa kwepamusoro runogonawo kupa simbi chimiro chekushongedza, uye chigadziko chinoshanda chemhando dzakawanda dzependi.Kwete izvozvo chete, asi inobvumirawo simbi kuti ichengetedze maitiro ayo emagetsi.

Painting

Kupenda kunosanganisira kupfapfaidza runyoro rwepende pamusoro pechikamu.Mavara anogona kuenzaniswa nenhamba yerudzi rwePantone yesarudzo yemutengi, nepo kupera kutangira kubva kune matte kusvika kugloss kusvika kusimbi.

Black oxide

Black oxide inoshandura coating yakafanana neAlodine iyo inoshandiswa simbi uye simbi isina tsvina.Inonyanya kushandiswa pakuonekwa uye kune zvinyoro zvinyoro zvekuramba.

Chikamu chekumaka

Chikamu chekumaka inzira inodhura yekuwedzera marogo kana mabhii echinyakare kune ako madhizaini uye anowanzo shandiswa kune yakajairwa chikamu chekumaka panguva yakazara-chiyero kugadzirwa.

| Item | Inowanikwa Surface Inopedzisa | Function | Coating Kuonekwa | Ukobvu | Standard | Yakakodzera Material |

| 1 | Bvisa Anodize | Kudzivirira oxidation, anti-friction, shongedza chimiro | Zvakajeka, Dema, Bhuruu, Girini, Ndarama, Tsvuku | 20-30μm | ISO7599, ISO8078, ISO8079 | Aluminium uye alloy yayo |

| 2 | Zvakaoma Anodize | Anti-oxidizing, Anti-stacic, inowedzera abrasion kuramba uye kuoma kwepamusoro, kushongedza | Nhema | 30-40μm | ISO10074, BS/DIN 2536 | Aluminium uye alloy yayo |

| 3 | Alodine | Wedzera corrosion resistance, kuwedzera chimiro chepamusoro uye kuchena | Pachena, isina ruvara, iridescent yero, brown, grey, kana bhuruu | 0.25-1.0μm | Mil-DTL-5541, MIL-DTL-81706, Mil-spec zviyero | Various Metal |

| 4 | Chrome Plating / Hard Chrome Plating | Corrosion resistance, kuwedzera kuomarara kwepasi uye kusaramba kweabrasion, Anti=rusty, kushongedza | Ndarama, Sirivha Inopenya | 1-1.5μm Zvakaoma:8-12μm | Tsanangudzo SAE-AME-QQ-C-320, Kirasi 2E | Aluminium uye alloy yayo Steel uye alloy yayo |

| 5 | Electroless Nickel Plating | Kushongedza, kudzivirira ngura, kuwedzera kuomarara, kusaita ngura | Bright, light yellow | 3-5μm | MIL-C-26074, ASTM8733 UYE AMS2404 | Yakasiyana Metal, simbi uye Aluminium alloy |

| 6 | Zinc Plating | Anti-ngura, kushongedza, kuwedzera marara kuramba | Bhuruu, Ichena, Tsvuku, Yero, Nhema | 8-12μm | ISO/TR 20491, ASTM B695 | Various Metal |

| 7 | Ndarama / Silver Plating | Eletric uye electromagnetic wave conduction, kushongedza | Goridhe, Sirivha Inopenya | Ndarama: 0.8-1.2μm Sirivha:7-12μm | MIL-G-45204, ASTM B488, AMS 2422 | Steel uye alloy yayo |

| 8 | Black oxide | Anti-ngura, kushongedza | Dema, Bhuruu dema | 0.5-1μm | ISO11408, MIL-DTL-13924, AMS2485 | Stainless Simbi, Chromium Simbi |

| 9 | Upfu Paint / Painting | kurwisa ngura, kushongedza | Dema kana chero kodhi yeRal kana nhamba yePantone | 2-72μm | Yakasiyana kambani standard | Various metal |

| 10 | Passivation yeStainless Steel | Anti-ngura, kushongedza | Hapana chenjedzo | 0.3-0.6μm | ASTM A967, AMS2700&QQ-P-35 | Simbi isina ngura |

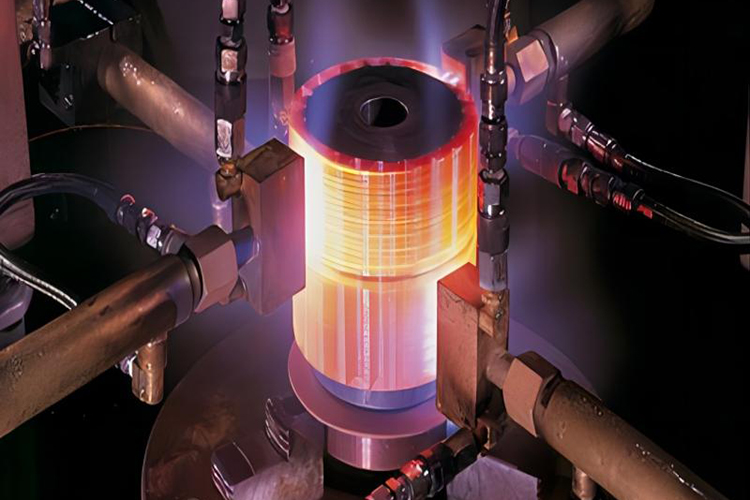

Kurapa Kupisa

Kurapa kwekupisa inhanho yakakosha mukugadzira machining.Nekudaro, kune inopfuura nzira imwe yekuzviita, uye sarudzo yako yekurapa yekupisa zvinoenderana nezvinhu, indasitiri uye yekupedzisira application.

Kupisa Kurapa Services

Kupisa kurapa simbiHeat kurapa ndiyo nzira iyo simbi inodziisa kana kutonhodzwa munzvimbo yakanyatsodzorwa kuti ishandise zvimiro zvemuviri zvakaita sekusagadzikana kwayo, kusimba, kugadzirwa, kuoma, uye kusimba.Simbi dzinodziya-kupisa dzakakosha kune akawanda maindasitiri anosanganisira aerospace, mota, komputa, uye maindasitiri emidziyo inorema.Kupisa kunopisa simbi (senge screws kana injini brackets) inogadzira kukosha nekuvandudza kugona kwayo uye kushanda kwayo.

Kurapa kwekupisa inhanho nhatu.Chekutanga, simbi inodziyirwa kune chaiyo tembiricha inodiwa kuunza shanduko inodiwa.Zvadaro, kutonhora kunochengetwa kusvikira simbi yave ichipisa zvakaenzana.Mhepo inopisa inobva yabviswa, zvichiita kuti simbi itonhore zvachose.

Simbi ndiyo inonyanya kushandiswa kupisa simbi asi maitiro aya anoitwa pane zvimwe zvinhu:

● Aluminium

● Brass

● Bronze

● Kanda Simbi

● Mhangura

● Hastelloy

● Inconel

● Nickel

● Purasitiki

● Simbi Isina Stainless

Iwo akasiyana Heat Treatment Options

Kuomesa:Kuomesa kunoitwa kugadzirisa kushomeka kwesimbi, kunyanya izvo zvinokanganisa kusimba kwese.Inoitwa nekupisa simbi uye kuidzima nekukurumidza kana yasvika kune inodiwa zvinhu.Izvi zvinoomesa zvimedu kuti zviwane hunhu hutsva.

Kuomesa:Kuomesa kunoitwa kugadzirisa kushomeka kwesimbi, kunyanya izvo zvinokanganisa kusimba kwese.Inoitwa nekupisa simbi uye kuidzima nekukurumidza kana yasvika kune inodiwa zvinhu.Izvi zvinoomesa zvimedu kuti zviwane hunhu hutsva.

Annealing:Zvakanyanya kuzivikanwa nealuminium, mhangura, simbi, sirivheri kana ndarira, annealing inosanganisira kupisa simbi kusvika pakupisa kwakanyanya, kuibata ipapo uye kuibvumira kuti itonhorere zvishoma nezvishoma.Izvi zvinoita kuti simbi idzi dzive nyore kushanda kuita chimiro.Mhangura, sirivheri nendarira zvinogona kutonhodzwa nekukasira kana zvishoma nezvishoma, zvichienderana nekushandiswa, asi simbi inofanira kugara ichitonhorera zvishoma nezvishoma kana kuti haizonyura zvakanaka.Izvi zvinowanzoitwa pamberi pekugadzira kuitira kuti zvinhu zvisakundikana panguva yekugadzira.

Normalizing:Kazhinji inoshandiswa pasimbi, normalizing inovandudza machinability, ductility uye simba.Simbi inopisa kusvika 150 kusvika 200 madhigirii kupisa kupfuura simbi dzinoshandiswa mukuita annealing uye inochengetwa ipapo kusvika shanduko yaunoda yaitika.Maitiro acho anoda simbi kumhepo inotonhorera kuitira kugadzira yakanatswa ferritic tsanga.Izvi zvinobatsirawo pakubvisa columnar zviyo uye dendritic segregation, iyo inogona kukanganisa kunaka uchikanda chikamu.

Kupisa:Iyi nzira inoshandiswa kune iron-based alloys, kunyanya simbi.Aya maalloys akaoma zvakanyanya, asi anowanzo brittle kune zvavanoda.Kupisa kunopisa simbi kusvika kune tembiricha iri pazasi penzvimbo yakaoma, sezvo izvi zvichideredza brittleness pasina kukanganisa kuoma.Kana mutengi achishuvira zviri nani plastiki ine kuomarara kushoma uye kusimba, isu tinopisa simbi kune tembiricha yepamusoro.Dzimwe nguva, kunyanguvezvo, zvinhu zvinoramba zvichidzika, uye zvingava nyore kutenga zvinhu zvinenge zvatooma kana kuti kuomesa usati wagadzira.

Kuomesa nyaya: Kana iwe uchida nzvimbo yakaoma asi yakapfava musimboti, kuomeswa kwekesi ndiko kubheja kwako kwakanyanya.Iyi ndiyo nzira yakajairika yesimbi ine kabhoni shoma, sesimbi nesimbi.Nenzira iyi, kurapwa kwekupisa kunowedzera kabhoni kumusoro.Iwe unozowanzo kuodha sevhisi iyi mushure mekunge zvidimbu zvagadzirwa kuitira kuti iwe ugone kuzviita kuti zviwedzere kusimba.Inoitwa nekushandisa kupisa kwakanyanya nemamwe makemikari, sezvo izvo zvinoderedza njodzi yekuita kuti chikamu chiite brittle.

KuchemberaIyo inozivikanwawo sekunaya kwemvura, maitiro aya anowedzera simba regoho resimbi dzakapfava.Kana simbi ichida kuwedzera kuomesa kupfuura chimiro chayo chazvino, kuomesa kwemvura kunowedzera tsvina kuwedzera simba.Iyi nzira inowanzoitika mushure mekunge dzimwe nzira dzashandiswa, uye inongosimudza tembiricha kusvika pakati uye inotonhorera zvinhu nekukurumidza.Kana nyanzvi yakasarudza kuchembera kwepanyama kwakanakisa, zvinhu zvinochengetwa munzvimbo inotonhorera kusvika zvasvika kune zvinodiwa.