Kushandiswa kwePlastiki Materials

In Field Manufacturing

01

Plastiki zvinhu uye mashandisiro azvo mukatikugadzira motokari

● Polypropylene (PP): Polypropylene ipurasitiki yakajairika ine uremu huremu, kupikisa kwemakemikari uye mari shoma.Mumunda wemotokari, polypropylene inowanzoshandiswa mukugadzira zvikamu zvemukati zvemotokari, mabhokisi ekuchengetedza uye mabumpers, nezvimwe.

● Polycarbonate (PC): Polycarbonate ine maitiro ekusimba kwepamusoro, kukanganisa kupikisa uye kujekesa kwakanaka.Mumunda wemotokari, polycarbonate inowanzoshandiswa mukugadzira marambi emotokari, dzimba dzegirazi uye mapaneru emidziyo, nezvimwe.

02

Plastiki zvinhu uye mashandisiro azvo mukatirobhoti kugadzira

● Polypropylene (PP): Polypropylene ipurasitiki inowanikwa yakawanda iyo isingaremi, inopesana nekemikari uye inodhura yezvikamu zverobhoti uye zvibatanidza.Semuyenzaniso, robhoti zvikamu, mabhuraketi uye connectors kazhinji CNC machined kubva polypropylene.

● Polystyrene (PS): Polystyrene ipurasitiki yakareruka, yakaoma uye yakaderera-yakaderera inokodzera kuumbwa uye kudzivirira zvikamu zvemarobhoti.Semuenzaniso, mafuremu, mabhesi, uye zvivharo zvemarobhoti zvinowanzogadzirwa kubva ku polystyrene.

03

Plastiki zvinhu uye mashandisiro azvo mukatiKugadzirwa kwezvokurapa

● ABS (Acrylonitrile Butadiene Styrene): ABS ipurasitiki inoshandiswa zvakasiyana-siyana uye inopesana nemhepo inowanzoshandiswa mukugadzira michina yezvokurapa.Inowanzo shandiswa kumakasi, dzimba, uye zvimiro zvemidziyo yekurapa senge michina yekufungidzira, masisitimu ekutarisa, uye zviridzwa zverabhoritari.

● Polyetheretherketone (PEEK): PEEK ndeyepamusoro-performance thermoplastic material inozivikanwa nokuda kwemaitiro ayo ekugadzirisa zvinhu, makemikari anopikisa, uye biocompatibility.Inowanzo shandiswa mukugadzira midziyo yekurapa inosimwa, midziyo yekuvhiya, uye zvikamu zvinoda simba rakawanda uye kuramba kune sterilization maitiro.

Nhanganyaya kuPlastiki Machining

Plastic machined parts inzira isingaremi uye inodhura kune dzimwe nhengo dzesimbi.Izvo zviri nyore kugadzira muchina uye kupa kuenderana neyakasiyana mapurasitiki.CNC machining isarudzo yakakurumbira yeinjiniya uye zvikwata zvechigadzirwa nekuda kwekusiyana kwayo.Mhando dzakasiyana dzemapurasitiki ane masimba avo uye kushaya simba kweCNC machining application.

Plastic Machining Services

Kambani yedu inopa mamiriro-e-e-e-e-art epurasitiki CNC machining masevhisi ane tarisiro pane inowirirana mhando uye nekukurumidza kutendeuka nguva.Nezvikepe zvakakura zvekugaya uye kutenderedza michina, isu tine kugona kubata maodha echero saizi, kubva kune madiki prototypes kune yakaoma kugadzirwa inomhanya.Netiweki yedu yakakura yevagadziri inoita kuti tikwanise kushanda nemapurasitiki akasiyana siyana uye nekupa akasiyana epamusoro pekupedzisira sarudzo.Isu takatsaurirwa kusangana nezvinodiwa nevatengi vedu uye nekupa zvinodhura mhinduro.

Zvakanakira zveCNC Plastic Machining

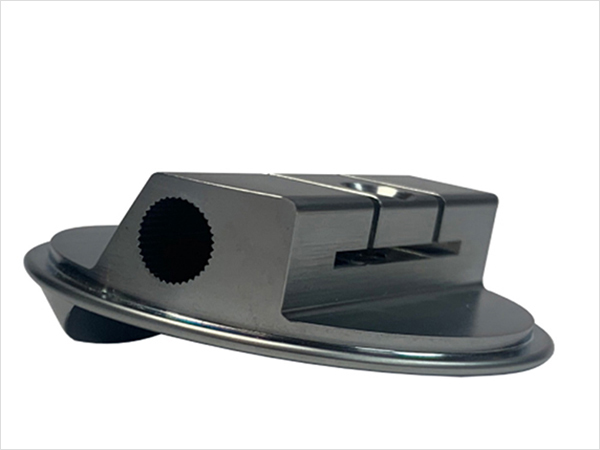

CNC plastiki machining inzira yekubvisa iyo inobvumira kugadzirwa kwezvinhu zvakaomarara zvepurasitiki zvikamu.Yedu yakaomesesa 3-, 4-, uye 5-axis CNC michina inogona kugadzira emhando yepamusoro zvikamu zvine yakaoma geometries.Kuenzaniswa ne3D kudhinda kana jekiseni kuumba, CNC machining inopa kushivirira kwakasimba uye kusarudzwa kwakakura kwezvinhu zvepolymer.Iyo inonyanya kudhura-inoshanda kune yakaderera vhoriyamu kugadzira.Nekusimudzira yedu yakakura CNC epurasitiki machining supply cheni, tinogona kuendesa yakavimbika uye inoshanda mhinduro kune ako epurasitiki machining zvinodiwa.

Materials Comparison Table

| Plastiki | Color | Melting point | Density | Hunhu |

| PEEK | Nhema | 150 ℃ | 1.51 | 1.Good kuoma uye kukanganisa kupikisa |

| 2.Good simba uye kuoma, nyore kurodza banga | ||||

| 3.Excellent UV resistance |

| Plastiki | Color | Melting point | Density | Hunhu |

| POM | Black&White | 160 ℃ | 1.41 | 1.High solvent corrosion resistance |

| 2.High tensile resistance | ||||

| 3.Good magetsi ekudzivirira | ||||

| 4.Good sliding uye abrasion resistance |

| Plastiki | Color | Melting point | Density | Hunhu |

| PA | Creamy White | 220 ℃ | 1.14 | 1.Thermal deformation |

| 2.Good slippability uye yakakwirira kugadzikana kwemakemikari | ||||

| 3.High evaporationb |

| Plastiki | Color | Melting point | Density | Hunhu |

| PC | Transparent, Dark Brown | 150 ℃ | 1.2 | 1.Kupisa-kusagadzikana kwekusagadzikana |

| 2.Good magetsi ekudzivirira | ||||

| 3.Kutora mvura yakaderera, kuzvidzima | ||||

| 4.High kukanganisa kuoma |

| Plastiki | Color | Melting point | Density | Hunhu |

| PU | Amber | 260 ℃ | 1.24 | Yakanaka elasticity uye kuoma, yakakodzera kugadzira elastic gasket |