Pamwamba Kumaliza kwa CNC Machining

Kutsiliza pamwamba ndi njira yomwe imathandiza kufotokozera ndi kuyeretsa mawonekedwe onse pambuyo pa makina a CNC.

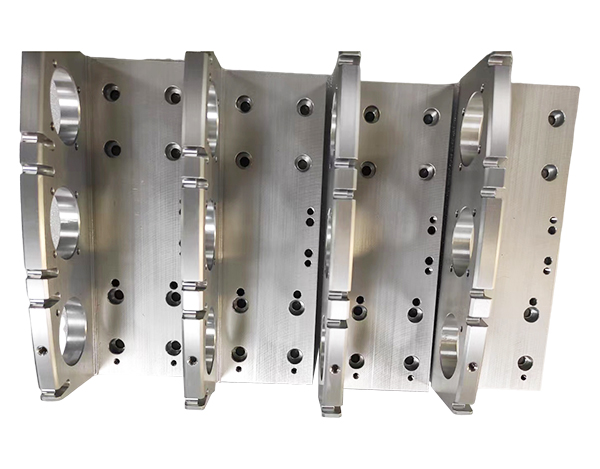

Ku Kachi, ndife oyendetsedwa bwino komanso okonzeka kusintha magawo azinthu zosiyanasiyana.Kaya mukutsatira zololera zolimba komanso zomaliza zosalala kapena mukufuna dzimbiri komanso kukana kuvala, kumaliza kwathu kwa makina a CNC kumatha kupanga zomwe mukufuna.

Kodi Machining Surface Finish ndi chiyani?

Kutsirizitsa kwapamwamba kumaphatikizapo njira yosinthira pamwamba pazitsulo pokonzanso, kuchotsa kapena kuwonjezera, ndipo amagwiritsidwa ntchito poyesa mawonekedwe onse a pamwamba omwe amadziwika ndi:

Lay- Mayendedwe a mawonekedwe apamwamba kwambiri (nthawi zambiri amatsimikiziridwa ndi njira yopangira).

Waviness- Imakhudzana ndi zolakwika kapena zolakwika zokulirapo, monga zokhotakhota kapena zopatuka kuchokera pazomwe zafotokozedwa.

Kukalipa Pamwamba- Mulingo wa zolakwika zotalikirana bwino.Nthawi zambiri, kuuma kwapamtunda ndizomwe akatswiri amatcha "kumaliza pamwamba" pomwe kugwiritsa ntchito "mawonekedwe apamwamba" kumakhala kofala pokhudzana ndi mawonekedwe onse atatu.

Ndi zinthu ziti zomwe muyenera kuziganizira posankha kumaliza kwa makina a CNC?

Kagwiritsidwe ntchito ka mankhwala

Zinthu zosiyanasiyana zachilengedwe, monga kugwedezeka, kutentha, chinyezi, ma radiation a UV, ndi zina zambiri, zimagwiritsidwa ntchito pazigawo zosiyanasiyana zamakina a CNC.Mungasankhe mwanzeru ngati muganizira mozama za ndani ndi zomwe mankhwalawo akupangira.

Kukhalitsa

Kodi mukufuna kuti mankhwala anu azikhala nthawi yayitali bwanji ndi funso lomwe muyenera kudzifunsa.Kupanga kumaphatikizapo zambiri zokhalitsa.The zopangira ndi zofunika pamenepa, koma muyenera kuganizira Machining pamwamba kupukuta.Kukhalitsa ndi chinthu chomwe chimapangitsa kuti mtengo wanu ukhale wabwino.Chifukwa chake, muyenera kusankha kumaliza koyenera.

Miyeso ya gawo

Ndikofunikira kukumbukira kuti kumaliza kwa makina kumatha kusintha magawo a gawo.Zokhuthala ngati zokutira ufa zimatha kukulitsa makulidwe a chinthu chachitsulo.

Ubwino wa Metal Surface Finishing Process

Ntchito zochizira zitsulo pamwamba zitha kufotokozedwa mwachidule motere:

● Kongoletsani maonekedwe

● Onjezani mitundu yeniyeni yokongola

● Sinthani kuwala

● Limbikitsani kukana kwa mankhwala

● Wonjezerani kukana kuvala

● Chepetsani kuwonongeka kwa dzimbiri

● Chepetsani kukangana

● Chotsani zolakwika

● Kuyeretsa ziwalo

● Gwiritsani ntchito ngati malaya oyambira

● Sinthani masaizi ake

Ku Kachi, gulu lathu la akatswiri la akatswiri lidzalangiza za mankhwala abwino a pamwamba ndi njira zomaliza kuti mukwaniritse zotsatira zomwe mukufuna.Njira zochiritsira zomwe zilipo kale zikuphatikiza izi:

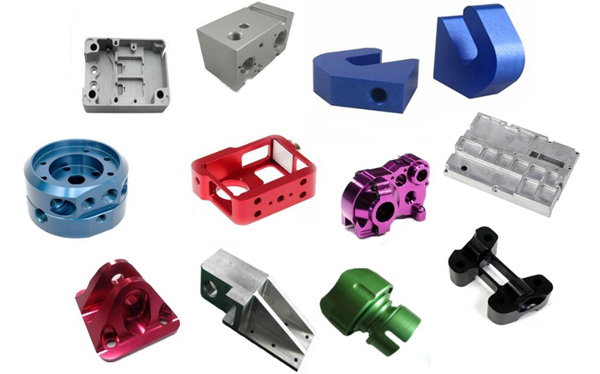

Anodize

Anodize ndi njira ya electrolytic passivation yomwe imakulitsa kusanjikiza kwachilengedwe kwa okusayidi pazigawo za aluminiyamu kuti zitetezedwe kuti zisavale ndi dzimbiri, komanso zodzikongoletsera.

Kuphulika kwa Mikanda

Kuphulika kwa media kumagwiritsa ntchito jeti yoponderezedwa ya abrasive media kuti ipaka matte, kumaliza kofanana pamwamba pazigawo.

Electroplating

Nickel plating ndi njira yomwe imagwiritsidwa ntchito popangira faifi tambala wopyapyala pagawo lachitsulo.Kuyika uku kumatha kugwiritsidwa ntchito ngati dzimbiri komanso kukana kuvala, komanso kukongoletsa.

Kupukutira

Zida zama makina a CNC zimapukutidwa pamanja mbali zingapo.Pamwambapo ndi yosalala komanso yonyezimira pang'ono.

Chromate

Mankhwala a chromate amagwiritsa ntchito chromium pamwamba pazitsulo, zomwe zimapangitsa kuti chitsulocho chisachite dzimbiri.Mtundu woterewu umatha kupatsanso chitsulo mawonekedwe okongoletsera, ndipo ndi maziko abwino a mitundu yambiri ya utoto.Osati zokhazo, komanso zimathandiza kuti zitsulo zisunge magetsi ake.

Kujambula

Kupenta kumaphatikizapo kupopera utoto wosanjikiza pamwamba pa gawolo.Mitundu imatha kufananizidwa ndi nambala yamtundu wa Pantone yomwe kasitomala wasankha, pomwe zomaliza zimayambira matte mpaka gloss mpaka zitsulo.

Black oxide

Black okusayidi ndi zokutira kutembenuka ofanana ndi Alodine kuti ntchito zitsulo ndi zitsulo zosapanga dzimbiri.Amagwiritsidwa ntchito makamaka pakuoneka komanso kukana dzimbiri pang'ono.

Kuyika chizindikiro

Kuyika chizindikiro ndi njira yotsika mtengo yowonjezerera ma logo kapena zilembo zamapangidwe pamapangidwe anu ndipo nthawi zambiri imagwiritsidwa ntchito polemba ma tag amtundu wanthawi zonse popanga zonse.

| Kanthu | Zomaliza Zopezeka Pamwamba | Ntchito | Kuphimba Mawonekedwe | Makulidwe | Standard | Zinthu Zoyenera |

| 1 | Chotsani Anodize | Kupewa kwa okosijeni, anti-friction, kukongoletsa chithunzi | Woyera, Wakuda, Wabuluu, Wobiriwira, Golide, Wofiira | 20-30μm | ISO7599, ISO8078, ISO8079 | Aluminium ndi aloyi ake |

| 2 | Zovuta Anodize | Anti-oxidizing, Anti-stacic, kuwonjezera kukana abrasion ndi kuuma pamwamba, kukongoletsa | Wakuda | 30-40μm | ISO10074, BS/DIN 2536 | Aluminium ndi aloyi ake |

| 3 | Alodine | Wonjezerani kukana kwa dzimbiri, onjezerani mawonekedwe a pamwamba ndi kuyeretsa | Zowoneka bwino, zopanda mtundu, zachikasu, zofiirira, zotuwa, kapena zabuluu | 0.25-1.0μm | Mil-DTL-5541, MIL-DTL-81706, Mil-spec miyezo | Mitundu yosiyanasiyana ya Metal |

| 4 | Chrome Plating / Hard Chrome Plating | Kulimbana ndi dzimbiri, kumawonjezera kuuma kwa pamwamba ndi kukana ma abrasion, Anti= dzimbiri, kukongoletsa | Golide, Siliva Wowala | 1-1.5μm Kulimba: 8-12μm | Malingaliro SAE-AME-QQ-C-320, Kalasi 2E | Aluminium ndi aloyi ake Chitsulo ndi aloyi ake |

| 5 | Electroless Nickel Plating | Kukongoletsa, kupewa dzimbiri, kuwonjezera kuuma, kukana dzimbiri | Chowala, chikasu chowala | 3-5 m | MIL-C-26074, ASTM8733 NDI AMS2404 | Zosiyanasiyana zitsulo, zitsulo ndi Aluminium alloy |

| 6 | Zinc Plating | Anti-dzimbiri, kukongoletsa, kuwonjezera kukana dzimbiri | Blue, White, Red, Yellow, Black | 8-12μm | ISO/TR 20491, ASTM B695 | Mitundu yosiyanasiyana ya Metal |

| 7 | Golide / Silver Plating | Eletric ndi electromagnetic wave conduction, zokongoletsera | Golide, Siliva Wowala | Golide: 0.8-1.2μm Siliva: 7-12μm | MIL-G-45204, ASTM B488, AMS 2422 | Chitsulo ndi aloyi ake |

| 8 | Black oxide | Anti-dzimbiri, kukongoletsa | Black, Blue wakuda | 0.5-1μm | ISO11408, MIL-DTL-13924, AMS2485 | Chitsulo chosapanga dzimbiri, Chromium Steel |

| 9 | Ufa Wopenta / Painting | kukana dzimbiri, kukongoletsa | Black kapena Ral code kapena Pantone nambala | 2-72μm | Zosiyanasiyana zamakampani | Zitsulo zosiyanasiyana |

| 10 | Passivation of Stainless Steel | Anti-dzimbiri, kukongoletsa | Palibe kuchenjeza | 0.3-0.6μm | ASTM A967, AMS2700&QQ-P-35 | Chitsulo chosapanga dzimbiri |

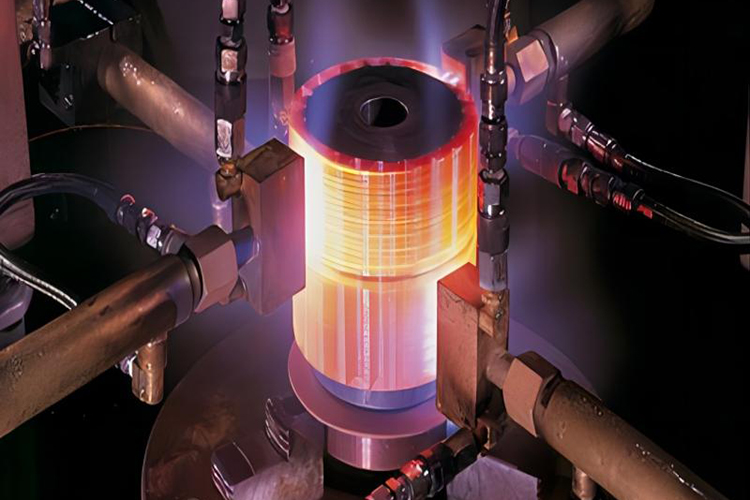

Kutentha Kuchiza

Kuchiza kutentha ndi gawo lofunikira pakuwongolera molondola.Komabe, pali njira yopitilira imodzi yokwaniritsira, ndipo kusankha kwanu chithandizo cha kutentha kumatengera zida, mafakitale ndi kugwiritsa ntchito komaliza.

Ntchito Zochizira Kutentha

Heat treatment metalHeat treatment ndi njira yomwe chitsulo chimatenthetsera kapena kuziziritsidwa m'malo otetezedwa mwamphamvu kuti chiwongolere zinthu zakuthupi monga kusinthika kwake, kulimba, kupangidwa, kuuma, ndi mphamvu.Zitsulo zothiridwa ndi kutentha ndizofunikira m'mafakitale ambiri kuphatikiza azamlengalenga, magalimoto, makompyuta, ndi zida zolemera.Zigawo zazitsulo zopangira kutentha (monga zomangira kapena mabulaketi a injini) zimapanga phindu popititsa patsogolo kusinthasintha kwake komanso kugwira ntchito kwake.

Chithandizo cha kutentha ndi njira zitatu.Choyamba, chitsulocho chimatenthedwa ndi kutentha kwapadera komwe kumafunika kubweretsa kusintha komwe kukufunika.Kenaka, kutentha kumasungidwa mpaka chitsulocho chatenthedwa mofanana.Kenako gwero la kutentha limachotsedwa, kulola chitsulo kuti chizizizira kotheratu.

Chitsulo ndiye chitsulo chogwiritsidwa ntchito kwambiri ndi kutentha koma izi zimachitika pazida zina:

● Aluminiyamu

● Mkuwa

● Mkuwa

● Chitsulo Choponyera

● Mkuwa

● Mofulumira

● Chotsani

● Nickel

● Pulasitiki

● Chitsulo Chosapanga chitsulo

Njira Zosiyanasiyana Zochizira Kutentha

Kuwumitsa:Kuumitsa kumachitidwa pofuna kuthana ndi zofooka zachitsulo, makamaka zomwe zimakhudza kulimba kwathunthu.Zimachitidwa ndi kutentha zitsulo ndikuzimitsa mwamsanga pamene zifika kuzinthu zomwe zikufunikira.Izi amaundana particles kotero amapeza makhalidwe atsopano.

Kuwumitsa:Kuumitsa kumachitidwa pofuna kuthana ndi zofooka zachitsulo, makamaka zomwe zimakhudza kulimba kwathunthu.Zimachitidwa ndi kutentha zitsulo ndikuzimitsa mwamsanga pamene zifika kuzinthu zomwe zikufunikira.Izi amaundana particles kotero amapeza makhalidwe atsopano.

Annealing:Zofala kwambiri ndi aluminiyamu, mkuwa, chitsulo, siliva kapena mkuwa, annealing imaphatikizapo kutentha zitsulo mpaka kutentha kwambiri, kuzigwira pamenepo ndikuzilola kuti zizizizira pang'onopang'ono.Izi zimapangitsa kuti zitsulozi zikhale zosavuta kugwira ntchito.Mkuwa, siliva ndi mkuwa zimatha kuzizidwa mwachangu kapena pang'onopang'ono, kutengera momwe zagwiritsidwira ntchito, koma chitsulo nthawi zonse chimayenera kuzizirira pang'onopang'ono kapena sichingatseke bwino.Izi nthawi zambiri zimachitika musanapange makina kuti zida zisalephere popanga.

Normalizing:Nthawi zambiri ntchito zitsulo, normalizing bwino machinability, ductility ndi mphamvu.Chitsulo chimatentha mpaka madigiri 150 mpaka 200 kuposa zitsulo zomwe zimagwiritsidwa ntchito popanga annealing ndipo zimasungidwa pamenepo mpaka kusintha komwe kukufunika kuchitika.Njirayi imafuna chitsulo kuti chizizizira kuti chipange mbewu zoyengedwa bwino za ferritic.Izi ndizothandizanso pochotsa mbewu za columnar ndi tsankho la dendritic, zomwe zitha kusokoneza khalidwe pamene mukuponya gawo.

Kutentha:Njirayi imagwiritsidwa ntchito pazitsulo zopangidwa ndi chitsulo, makamaka zitsulo.Ma alloys awa ndi olimba kwambiri, koma nthawi zambiri amakhala osakhazikika pazolinga zawo.Kutentha kumatenthetsa zitsulo mpaka kutentha pansi pa malo ovuta, chifukwa izi zidzachepetsa brittleness popanda kusokoneza kuuma.Ngati kasitomala akufuna pulasitiki yabwino ndi kuuma pang'ono ndi mphamvu, timatenthetsa zitsulo mpaka kutentha kwakukulu.Komabe, nthaŵi zina zipangizo sizimatenthedwa, ndipo zingakhale zosavuta kugula zinthu zomwe zaumitsidwa kale kapena kuziumitsa musanazipange.

Kuwumitsa mlandu: Ngati mukufuna malo olimba koma pachimake chofewa, kuyimitsa milandu ndiye kubetcha kwanu kopambana.Izi ndizomwe zimachitika pazitsulo zokhala ndi carbon yochepa, monga chitsulo ndi chitsulo.Mwa njira iyi, chithandizo cha kutentha chimawonjezera carbon pamwamba.Nthawi zambiri mumayitanitsa izi zidutswa zitapangidwa kuti muzitha kuzipanga kukhala zolimba.Amachitidwa pogwiritsa ntchito kutentha kwakukulu ndi mankhwala ena, chifukwa amachepetsa chiopsezo chopangitsa kuti gawolo likhale lolimba.

Kukalamba:Zomwe zimadziwikanso kuti kuuma kwa mpweya, njirayi imawonjezera mphamvu zokolola zazitsulo zofewa.Ngati zitsulo zimafuna kuumitsa kwina kuposa momwe zilili panopa, kuuma kwa mvula kumawonjezera zonyansa kuti ziwonjezere mphamvu.Izi nthawi zambiri zimachitika njira zina zikagwiritsidwa ntchito, ndipo zimangowonjezera kutentha mpaka pakati ndikuziziritsa zinthu mwachangu.Ngati katswiri awona kuti ukalamba wachilengedwe ndi wabwino kwambiri, zida zimasungidwa m'malo ozizira mpaka zitafika zomwe zikufunika.