Nto Finishes rau CNC Machining

Deg xov yog txheej txheem uas pab txhais thiab kho kom zoo nkauj tag nrho tom qab CNC machining.

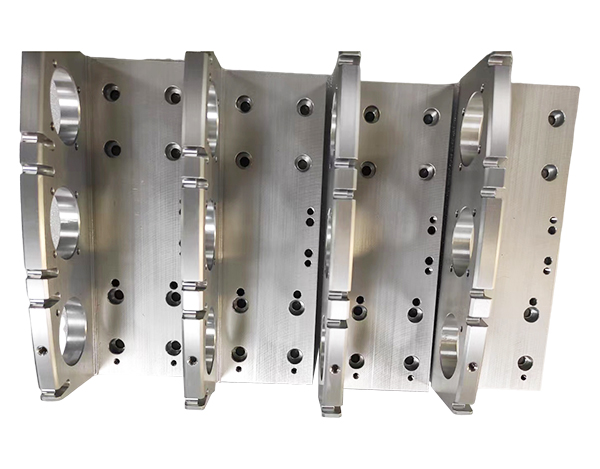

Ntawm Kachi, peb tau tsav zoo thiab npaj los kho qhov chaw rau ntau yam kev siv.Txawm hais tias koj tab tom ua raws li qhov ntev ntev thiab kev ua tiav du lossis xav tau kev txhim kho corrosion ntxiv thiab hnav tsis kam, peb cov khoom tiav rau CNC machining tuaj yeem tsim qhov koj xav tau.

Machining Surface Finish yog dab tsi?

Nto tiav nrog cov txheej txheem ntawm kev hloov cov hlau nto los ntawm kev hloov kho, tshem tawm lossis ntxiv, thiab siv los ntsuas qhov kev ntxhib los mos tag nrho ntawm qhov chaw uas yog:

Lay- Cov kev taw qhia ntawm cov qauv saum npoo av (feem ntau txiav txim siab los ntawm cov txheej txheem tsim khoom).

Waviness- Hais txog kev nthuav dav tsis zoo los yog coarser irregularities, xws li cov chaw uas warped los yog deflected los ntawm specifications.

Nto Roughness- Ib qho kev ntsuas ntawm finely spaced nto irregularities.Feem ntau, deg roughness yog dab tsi machinists hu ua "surface finish" thaum siv "surface texture" yog ib yam thaum hais txog tag nrho peb yam ntxwv.

Yam dab tsi los xav txog thaum xaiv CNC machining nto tiav?

Cov kev siv ntawm cov khoom

Txawv ib puag ncig yam, xws li kev vibrations, tshav kub, ya raws, UV hluav taws xob, thiab lwm yam, yog siv rau ntau yam CNC machined qhov chaw.Koj tuaj yeem xaiv qhov ntse yog tias koj ua tib zoo xav txog leej twg thiab qhov khoom yog dab tsi.

Durability

Ntev npaum li cas koj xav kom koj cov khoom kav ntev yog ib lo lus nug koj yuav tsum nug koj tus kheej.Manufacturing muaj ntau durability.Cov khoom siv raw yog qhov tseem ceeb hauv qhov no, tab sis koj kuj yuav tsum xav txog qhov machining nto polishing.Durability yog qhov tseem ceeb hauv kev txhim kho tus nqi ntawm koj cov khoom tiav.Yog li ntawd, koj yuav tsum xaiv qhov tsim nyog tiav.

Dimensions ntawm ib feem

Nws yog ib qho tseem ceeb kom nco ntsoov tias machining nto tiav tuaj yeem hloov pauv qhov loj me.Thick finishes zoo li hmoov txheej yuav ua rau kom lub thickness ntawm cov khoom hlau.

Qhov kom zoo dua ntawm Hlau Nto Finishing txheej txheem

Lub luag haujlwm ntawm kev kho hlau saum npoo tuaj yeem raug sau tseg raws li hauv qab no:

● Txhim kho qhov tsos

● Ntxiv cov xim zoo nkauj tshwj xeeb

● Hloov cov luster

● Txhim kho cov tshuaj tiv thaiv

● Ua kom hnav tsis kam

● Txwv cov teebmeem ntawm corrosion

● Txo kev sib txhuam

● Tshem tawm qhov tsis xws luag

● Ntxuav cov khoom

● Ua ib lub tsho primer

● Kho qhov ntau thiab tsawg

Ntawm Kachi, Peb pab pawg kws tshaj lij yuav qhia txog cov kev kho mob saum npoo zoo tshaj plaws thiab cov txheej txheem ua tiav kom ua tiav qhov koj xav tau.Cov txheej txheem kho saum npoo uas twb muaj lawm muaj xws li hauv qab no:

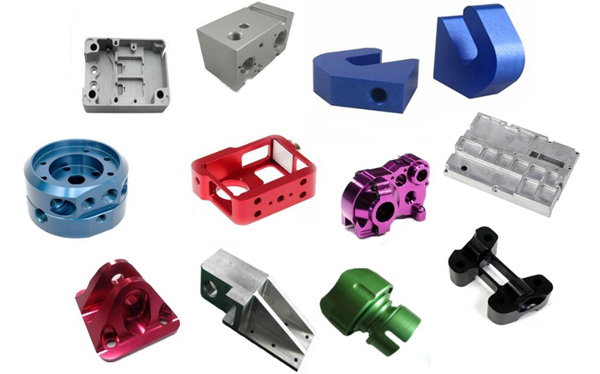

Anodize

Anodize yog cov txheej txheem electrolytic passivation uas loj hlob txheej txheem oxide ntawm txhuas qhov chaw rau kev tiv thaiv los ntawm kev hnav thiab corrosion, nrog rau cov teebmeem zoo nkauj.

Bead Blasting

Media blasting siv lub dav hlau pressurized ntawm abrasive xov xwm los thov ib tug matte, uniform tiav rau saum npoo ntawm qhov chaw.

Electroplating

Nickel plating yog txheej txheem siv los electroplate nyias txheej ntawm nickel mus rau ib qho hlau.Cov plating no tuaj yeem siv rau corrosion thiab hnav tsis kam, nrog rau kev kho kom zoo nkauj.

Polishing

Kev cai CNC machining qhov chaw yog manually polished nyob rau hauv ntau cov lus qhia.Qhov saum npoo yog du thiab me ntsis reflective.

Chromate

Cov kev kho mob chromate siv cov chromium compound rau cov hlau nto, muab cov hlau ua kom corrosion-resistant tag.Hom kev ua tiav no tuaj yeem muab cov hlau zoo nkauj, thiab nws yog lub hauv paus zoo rau ntau hom xim.Tsis tas li ntawd xwb, tab sis nws kuj tso cai rau cov hlau kom nws cov hluav taws xob conductivity.

Kev pleev xim

Painting yuav tsum tau txau ib txheej xim rau ntawm qhov chaw.Cov xim tuaj yeem sib phim rau Pantone xim tus naj npawb ntawm cov neeg siv khoom xaiv, thaum ua tiav ntau yam ntawm matte rau gloss rau xim hlau.

Dub Oxide

Dub oxide yog txheej txheej hloov dua siab tshiab zoo ib yam li Alodine uas yog siv rau cov hlau thiab stainless hlau.Nws yog siv tsuas yog rau cov tsos thiab rau me ntsis corrosion kuj.

Kev kos npe

Kev kos npe yog ib txoj hauv kev zoo rau kev ntxiv cov logos lossis kev cai sau rau koj cov qauv tsim thiab feem ntau yog siv rau kev cai ib feem tagging thaum lub sij hawm ua tiav.

| Yam khoom | Muaj Nto Ua tiav | Muaj nuj nqi | Txheej Txheej | Thickness | Txuj | Khoom siv tsim nyog |

| 1 | Ntshiab Anodize | Oxidation tiv thaiv, tiv thaiv kev sib txhuam, kho daim duab | Ntshiab, Dub, Xiav, Ntsuab, Kub, Liab | 20-30 m² | ISO7599, ISO8078, ISO8079 | Aluminium thiab nws cov alloy |

| 2 | Hard Anodize | Anti-oxidizing, Anti-stacic, nce abrasion kuj thiab deg hardness, decorating | Dub | 30-40 m² | ISO 10074, BS / DIN 2536 | Aluminium thiab nws cov alloy |

| 3 | Alodine | Ua kom muaj kev tiv thaiv corrosion, txhim kho cov qauv saum npoo thiab huv | Ntshiab, tsis muaj xim, iridescent daj, xim av, grey, los yog xiav | 0.25-1.0 hli | Mil-DTL-5541, MIL-DTL-81706, Mil-spec qauv | Ntau yam hlau |

| 4 | Chrome Plating / Hard Chrome Plating | Corrosion tsis kam, nce saum npoo hardness thiab abrasion tsis kam, Anti = xeb, decorating | Golden, ci nyiaj | 1-1.5 hli Nyhav: 8-12μm | Specification SAE-AME-QQ-C-320, Chav Kawm 2E | Aluminium thiab nws cov alloy Hlau thiab nws cov alloy |

| 5 | Electroless Nickel plating | Kho kom zoo nkauj, tiv thaiv xeb, txhim khu hardness, corrosion kuj | Ci ntsa iab, lub teeb daj | 3-5 m² | MIL-C-26074, ASTM8733 thiab AMS2404 | Ntau yam hlau, steel thiab Aluminium alloy |

| 6 | Zinc Plating | Anti-rusty, decorating, nce corrosion kuj | Xiav, Dawb, Liab, Daj, Dub | 8-12 m | ISO/TR 20491, ASTM B695 | Variious Hlau |

| 7 | Kub / Nyiaj Plating | Hluav taws xob thiab electro-magnetic yoj conduction, decorating | Golden, Bright Silver | Golden: 0.8-1.2μm Nyiaj: 7-12μm | MIL-G-45204, ASTM B488, AMS 2422 | Hlau thiab nws cov alloy |

| 8 | Dub Oxide | Anti-rusty, kho kom zoo nkauj | Dub, Xiav dub | 0.5-1 m | ISO11408, MIL-DTL-13924, AMS2485 | Stainless hlau, Chromium hlau |

| 9 | Hmoov Xim / Painting | corrosion kuj, decorating | Dub lossis ib qho Ral code lossis Pantone tus lej | 2-72 hli | Txawv tuam txhab qauv | Ntau yam hlau |

| 10 | Passivation ntawm Stainless Hlau | Anti-rusty, kho kom zoo nkauj | Tsis muaj alernation | 0.3-0.6 hli | ASTM A967, AMS2700 & QQ-P-35 | Stainless hlau |

Kev kho cua sov

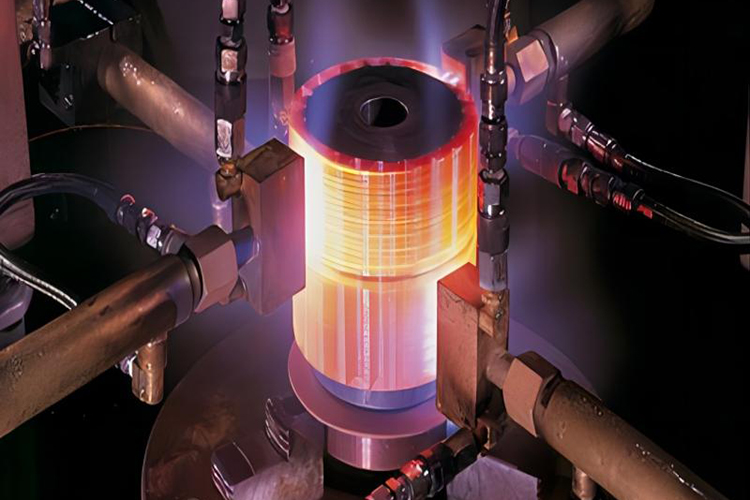

Kev kho cua sov yog ib kauj ruam tseem ceeb hauv precision machining.Txawm li cas los xij, muaj ntau tshaj li ib txoj hauv kev ua kom tiav, thiab koj qhov kev xaiv ntawm kev kho cua sov yog nyob ntawm cov ntaub ntawv, kev lag luam thiab daim ntawv thov zaum kawg.

Kev kho cua sov

Thaum tshav kub kub kho hlau Kev kho cua sov yog txheej txheem los ntawm cov hlau yog cua sov los yog txias hauv ib puag ncig nruj tswj kom tswj cov khoom siv lub cev xws li nws cov malleability, durability, fabricability, hardness, thiab lub zog.Thaum tshav kub kub-kho hlau yog qhov tseem ceeb rau ntau qhov kev lag luam xws li aerospace, automotive, computer, thiab cov cuab yeej siv hnyav.Thaum tshav kub kub kho cov hlau qhov chaw (xws li cov ntsia hlau lossis lub cav cav) tsim muaj txiaj ntsig los ntawm kev txhim kho lawv cov kev siv ntau yam thiab siv tau.

Kev kho cua sov yog txheej txheem peb kauj ruam.Ua ntej, cov hlau yog rhuab mus rau qhov tshwj xeeb kub uas yuav tsum tau coj mus txog qhov xav tau hloov.Tom ntej no, qhov kub thiab txias yog tswj kom txog thaum cov hlau tau sib npaug.Thaum tshav kub kub qhov chaw yog muab tshem tawm, cia cov hlau kom txias tag.

Hlau yog cov khoom siv hluav taws xob ntau tshaj plaws tab sis cov txheej txheem no tau ua rau lwm cov ntaub ntawv:

● Aluminium

● tooj dag

● Bronze

● Cam khwb cia hlau

● Tooj

● Hastelloy

● Inconel

● Nickel

● Yas

● Stainless Hlau

Cov kev xaiv kev kho cua sov sib txawv

Hardening:Hardening yog ua los daws cov hlau tsis txaus, tshwj xeeb tshaj yog cov uas cuam tshuam rau tag nrho cov kav ntev.Nws yog ua los ntawm cua sov cov hlau thiab quenching nws sai sai thaum nws ncav cuag cov khoom xav tau.Qhov no khov cov khoom kom nws tau txais cov txiaj ntsig tshiab.

Hardening:Hardening yog ua los daws cov hlau tsis txaus, tshwj xeeb tshaj yog cov uas cuam tshuam rau tag nrho cov kav ntev.Nws yog ua los ntawm cua sov cov hlau thiab quenching nws sai sai thaum nws ncav cuag cov khoom xav tau.Qhov no khov cov khoom kom nws tau txais cov txiaj ntsig tshiab.

Annealing:Feem ntau nrog txhuas, tooj liab, hlau, nyiaj los yog tooj dag, annealing muaj cua sov hlau mus rau qhov kub thiab txias, tuav nws nyob ntawd thiab cia nws maj mam txias.Qhov no ua rau cov hlau no yooj yim ua haujlwm rau hauv cov duab.Tooj, nyiaj thiab tooj dag tuaj yeem ua kom txias sai lossis maj mam, nyob ntawm daim ntawv thov, tab sis cov hlau yuav tsum tau txias maj mam los yog nws yuav tsis ua kom zoo.Qhov no feem ntau ua tiav ua ntej machining yog li cov ntaub ntawv tsis poob thaum tsim khoom.

Normalizing:Feem ntau siv rau steel, normalizing txhim kho machinability, ductility thiab lub zog.Hlau heats mus rau 150 mus rau 200 degrees kub dua li cov hlau siv nyob rau hauv cov txheej txheem annealing thiab tuav nyob ntawd kom txog rau thaum qhov kev hloov pauv xav tau tshwm sim.Cov txheej txheem yuav tsum tau hlau kom cua txias thiaj li tsim tau cov nplej refined ferritic.Qhov no kuj tseem muaj txiaj ntsig rau kev tshem tawm cov nplej nplej thiab dendritic cais tawm, uas tuaj yeem cuam tshuam qhov zoo thaum casting ib feem.

Tempering:Cov txheej txheem no yog siv rau cov hlau-raws li alloys, tshwj xeeb tshaj yog hlau.Cov alloys no nyuaj heev, tab sis feem ntau nkig heev rau lawv lub hom phiaj.Tempering heats hlau mus rau qhov kub qis dua qhov tseem ceeb, vim qhov no yuav txo cov brittleness yam tsis muaj kev cuam tshuam cov hardness.Yog tias tus neeg siv khoom xav kom zoo dua plasticity nrog tsawg hardness thiab lub zog, peb ua kom sov hlau kom kub dua.Qee lub sij hawm, txawm li cas los xij, cov khoom siv tiv taus tempering, thiab nws yuav yooj yim dua los yuav cov khoom uas twb tau tawv lawm los yog ua kom tawv nws ua ntej machining.

Case hardening: Yog tias koj xav tau lub ntsej muag tawv tab sis cov tub ntxhais softer, cov ntaub ntawv tawv tawv yog koj qhov zoo tshaj plaws thawj koom ruam.Qhov no yog ib qho txheej txheem rau cov hlau uas muaj cov pa roj carbon tsawg, xws li hlau thiab hlau.Hauv txoj kev no, kev kho cua sov ntxiv cov pa roj carbon monoxide rau saum npoo.Koj yuav nquag xaj qhov kev pabcuam no tom qab cov khoom raug machined kom koj tuaj yeem ua rau lawv ruaj khov.Nws yog ua los ntawm kev siv cov kub kub nrog rau lwm yam tshuaj, raws li qhov uas txo qhov kev pheej hmoo ntawm kev ua ib feem nkig.

Kev laus:Kuj hu ua nag lossis daus hardening, cov txheej txheem no ua rau kom muaj zog ntawm cov hlau softer.Yog hais tias hlau xav tau ntxiv hardening tshaj nws cov qauv tam sim no, nag lossis daus hardening ntxiv impurities kom muaj zog.Cov txheej txheem no feem ntau tshwm sim tom qab siv lwm txoj hauv kev, thiab nws tsuas yog nce qhov kub thiab txias mus rau theem nrab thiab txias cov khoom sai sai.Yog tias tus kws tshaj lij txiav txim siab tias kev laus yog qhov zoo tshaj plaws, cov ntaub ntawv khaws cia hauv qhov txias txias kom txog thaum lawv ncav cuag cov khoom xav tau.