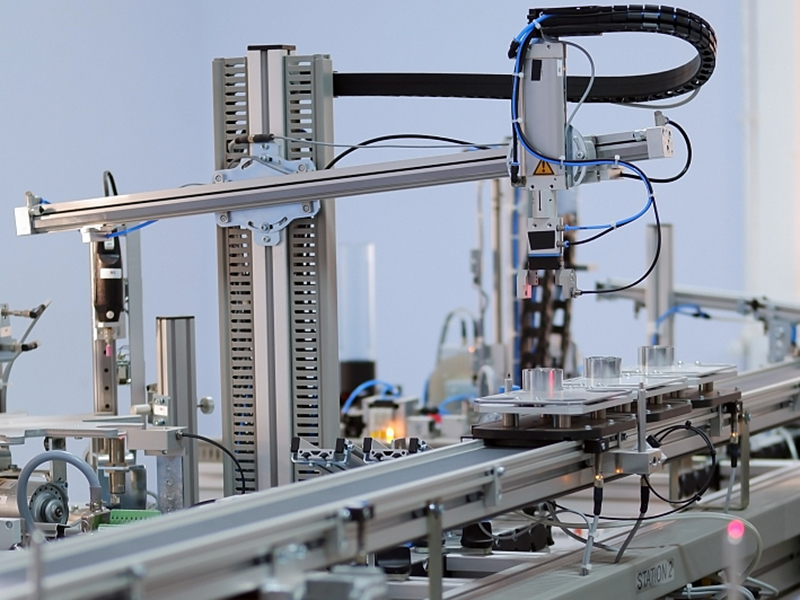

CNC Machining rau qhov chaw

Kev Lag Luam Robotics

● Ceev Prototyping thiab On-Demand Production

● Kev xaiv cov khoom siv

● Nto kho ntau yam.

● Tsawg ntim customization

CNC machining thiab robotics tau dhau los ua qhov tsis sib xws hauv kev lag luam automation niaj hnub no.Kev sib koom ua ke ntawm ob lub thev naus laus zis no yog qhov tseem ceeb vim tias lawv tsis yog sib tshooj xwb tab sis kuj ntxiv rau ib leeg.Kev siv cov neeg hlau tau zoo heev txhim kho lub peev xwm ntawm CNC machining, muab cov kev daws teeb meem zoo dua thiab raug automation.

Custom Prototypes Thiab Parts For

Kev lag luam Automation

Peb muab ntau yam kev daws teeb meem automation tsim los xa cov txiaj ntsig zoo rau koj qhov project tshwj xeeb.

Rapid Prototyping & On-Demand Production

Kev sib koom ua ke ntawm kev lag luam machining thiab kev lag luam automation yog tshwj xeeb tshaj yog pom nyob rau hauv cov teb ntawm prototyping ceev ceev thiab kev xav tau ntau lawm.Prototyping ceev ceev siv cov cuab yeej siv automation thiab thev naus laus zis los ua cov khoom lag luam sai sai rau kev sim thiab siv tau thaum lub sijhawm tsim khoom.Qhov no muaj peev xwm rau prototyping sai sai accelerates lub voj voog kev loj hlob ntawm cov khoom thiab txo cov nqi kev loj hlob thiab kev pheej hmoo.

Ntawm qhov tod tes, kev tsim khoom raws li qhov xav tau suav nrog kev tsim khoom raws li qhov xav tau tiag tiag kom txo cov khoom muag thiab cov nqi qis dua.Los ntawm kev npaj tsim khoom yooj yim thiab siv cov khoom siv automation, kev tsim khoom raws li qhov xav tau tuaj yeem teb sai sai rau cov kev xav tau ntawm kev lag luam thiab muab cov khoom lag luam customized thiab cov kev pabcuam.

Nyob rau hauv kev siv tswv yim, prototyping sai thiab on-demand ntau lawm txhawb nqa thiab ntxiv ib leeg.Prototyping ceev ceev ua kom muaj kev txheeb xyuas raws sij hawm thiab kho cov teeb meem, zam kev hloov pauv thiab rov ua dua tshiab hauv cov theem tom ntej.Designs validated los ntawm ceev prototyping tuaj yeem siv ncaj qha rau ntawm qhov xav tau ntau lawm, yog li ua kom lub sijhawm ua lag luam thiab txhim kho cov khoom zoo.

Txhawm rau kom ua tiav sai prototyping thiab kev tsim khoom raws li qhov xav tau, cov khoom siv automation thiab thev naus laus zis ua lub luag haujlwm tseem ceeb.CNC tshuab tuaj yeem ua tiav cov haujlwm ua haujlwm raws li cov ntaub ntawv tsim, muab siab precision thiab rov ua dua.IoT thiab sensor thev naus laus zis tuaj yeem saib xyuas ntau yam tsis muaj thiab cov ntaub ntawv hauv lub sijhawm tiag tiag thaum lub sijhawm tsim khoom, ua kom muaj kev txawj ntse tswj thiab ua kom zoo dua.Tsis tas li ntawd, virtual simulation thiab cov qauv digital tuaj yeem simulate thiab optimize cov khoom tsim thiab txheej txheem kev npaj ua ntej ntau lawm, txo qhov tsis raug thiab pov tseg.

Ua CNC Parts rau lub

Kev Lag Luam Robotics

CNC machining tuaj yeem siv rau hauv kev tsim cov khoom siv rau kev lag luam neeg hlau.Qhov xwm txheej ntawm kev siv neeg hlau feem ntau xav tau kev hloov kho tshwj xeeb rau lawv lub hom phiaj.Yog li ntawd, CNC machining yog txoj kev tsim khoom zoo tshaj plaws vim nws tso cai rau cov nqi tsim khoom ntawm cov khoom tshwj xeeb hauv cov khoom me me.Qee qhov piv txwv ntawm yuav ua li cas CNC machining yog siv los tsim cov khoom siv hlau muaj xws li:

1. Robotic end effectors:CNC machining tuaj yeem siv los tsim cov kev cai kawg effectors uas tau ua raws li cov haujlwm tshwj xeeb ua los ntawm cov neeg hlau.Cov txiaj ntsig kawg no yog qhov tseem ceeb rau kev ua kom cov neeg hlau cuam tshuam nrog thiab tswj cov khoom hauv lawv ib puag ncig.

2. Kev cai jigs thiab fixtures:CNC machining tuaj yeem siv los tsim tshwj xeeb jigs thiab fixtures los pab hauv kev sib dhos lossis kev sim cov txheej txheem ntawm cov tshuab neeg hlau.Cov cuab yeej kev cai no ua kom muaj kev sib raug zoo thiab qhov chaw ntawm cov khoom, ua kom tag nrho cov kev ua tau zoo thiab raug ntawm cov txheej txheem tsim khoom.

3. Khoom siv / ntu tuav thiab khaws cia:CNC machining tuaj yeem siv los tsim cov khoom siv hauv cov khoom siv neeg hlau lossis cov khoom siv ua haujlwm.Cov khoom no tuaj yeem suav nrog cov khoom tsim tshwj xeeb, cov tais, lossis cov khib nyiab cia uas ua rau cov neeg hlau ua haujlwm zoo thiab teeb tsa ntau yam khoom lossis qhov chaw thaum tsim khoom lossis sib dhos.

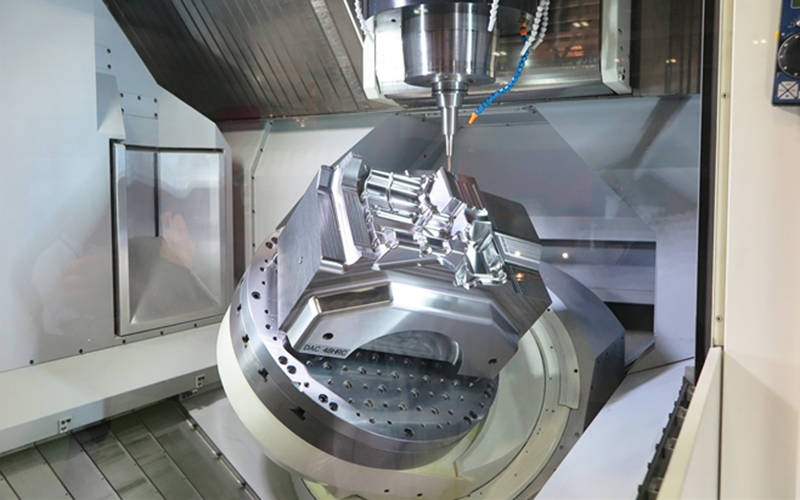

Cnc Machining yog qhov zoo rau kev tsim cov khoom siv hlau

Vim Muaj Ntau Yam Tseem Ceeb.

CNC machining muaj lub sijhawm hloov pauv sai, qhov ntev meej, thiab tswj qhov chaw tiav, ua rau nws zoo tagnrho rau kev cai neeg hlau.Nrog ceev tsim-rau-ib feem ntau lawm, nws tso cai rau kom ceev iteration thiab refinement.Qhov siab qhov tseeb qhov tseeb ua kom meej meej thiab rov ua dua, qhov tseem ceeb rau kev siv neeg hlau.Tsis tas li ntawd, CNC machining muab kev tswj xyuas meej ntawm qhov chaw tiaj tus thiab roughness, tseem ceeb rau kev tuav thiab nqus hauv kev ua haujlwm neeg hlau.

Nyob ntawm qhov nyuaj ntawm qhov kawg thiab qhov chaw tiav yuav tsum tau ua, robotic machining tuaj yeem pom tias yog lwm txoj hauv kev.

Robotic automation kuj tuaj yeem pab CNC machining

CNC tshuab automate qee cov kauj ruam ntau lawm, tab sis lwm tus xav tau tib neeg lossis neeg hlau ua haujlwm.Cov neeg hlau ua tau zoo ntawm cov haujlwm xws li thauj khoom, tswj cov txheej txheem, tshem tawm qhov chaw, thiab ua cov kev tshuaj xyuas zoo.Lawv txhim kho efficiency, precision, thiab kev nyab xeeb hauv kev ua haujlwm xws li milling thiab vuam.

Puas muaj lus nug rau peb?

Peb pab neeg muaj kev paub dhau los yuav pab koj thiab muab kev daws teeb meem rau koj qhov teeb meem.

Thov nrog peb hnub no!