CNC Machining for the

Robotics Industry

● Rapid Prototyping and On-Demand Production

● Material selection

● Surface treatment range.

● Low volume customization

CNC machining and robotics have become inseparable in today's industrial automation solutions. The synergy between these two technologies is critical as they not only overlap but also complement each other. The implementation of robotics has greatly enhanced the capabilities of CNC machining, providing more efficient and accurate automation solutions.

Custom Prototypes And Parts For

Automation Industry

We offer a range of automation solutions tailored to deliver optimal outcomes for your specific project.

Rapid Prototyping & On-Demand Production

The integration of the machining industry and the automation industry is particularly evident in the fields of rapid prototyping and on-demand production. Rapid prototyping utilizes automation equipment and technology to quickly manufacture product prototypes for testing and validation during the product development process. This ability for rapid prototyping significantly accelerates the product development cycle and reduces development costs and risks.

On the other hand, on-demand production involves producing based on actual demand to reduce inventory and lower costs. Through flexible production planning and the use of automation equipment, on-demand production can quickly respond to market demands and provide personalized customized products and services.

In practical applications, rapid prototyping and on-demand production support and complement each other. Rapid prototyping enables timely identification and correction of issues, avoiding costly modifications and remakes in later stages. Designs validated through rapid prototyping can be directly applied to on-demand production, thereby speeding up time to market and improving product quality.

To achieve rapid prototyping and on-demand production, automation equipment and technology play a crucial role. CNC machines can automatically execute machining operations based on design files, providing high precision and repeatability. IoT and sensor technology can monitor various parameters and data in real-time during the production process, enabling intelligent production control and optimization. Additionally, virtual simulation and digital models can simulate and optimize product design and process planning before production, reducing errors and waste.

Producing CNC Parts for the

Robotics Industry

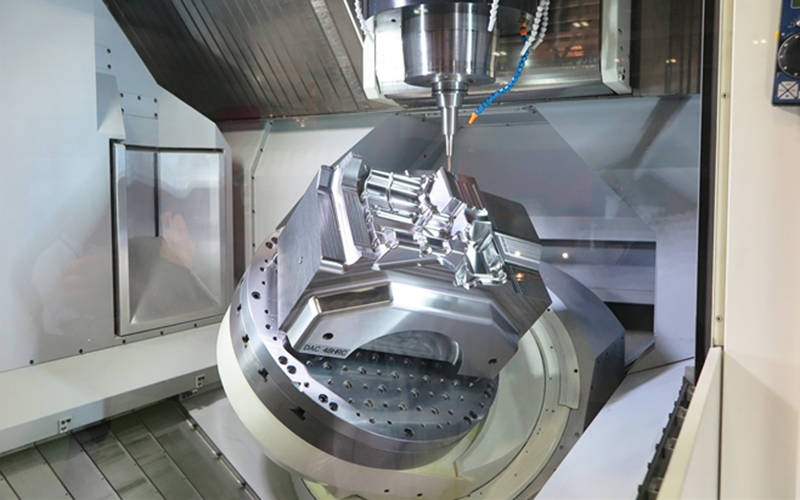

CNC machining can be used in the production of custom parts for the robotics industry. The nature of robotics applications often requires specific adaptations for their intended purpose. Therefore, CNC machining is the preferred manufacturing method as it allows cost-effective production of unique parts in small batches. Some examples of how CNC machining is utilized to manufacture robotic parts include:

1. Robotic end effectors: CNC machining can be used to manufacture custom end effectors that are tailored to the specific tasks performed by the robot. These end effectors are critical to enabling robots to interact with and manipulate objects in their environment.

2. Custom jigs and fixtures: CNC machining can be used to create specialized jigs and fixtures to assist in the assembly or testing process of robotic systems. These custom tools ensure precise alignment and positioning of components, increasing the overall efficiency and accuracy of the manufacturing process.

3. Material/part handling and storage: CNC machining can be used to produce components used in robotic material or part handling systems. These components may include custom-designed grippers, trays, or storage racks that enable robots to efficiently handle and organize various materials or parts during production or assembly.

Cnc Machining Is Preferred For Producing Robotic Parts

Due To Several Important Reasons.

CNC machining offers quick turnaround times, precise dimensions, and controlled surface finishes, making it ideal for custom robotics. With fast design-to-part production, it allows for rapid iteration and refinement. The high dimensional accuracy ensures precise and repeatable movements, crucial for robotics applications. Additionally, CNC machining provides precise control over surface flatness and roughness, important for gripping and suction in robotic operations.

Depending on the complexity of the final part and surface finish required, robotic machining can be seen as a viable alternative.

Robotic automation can also assist CNC machining

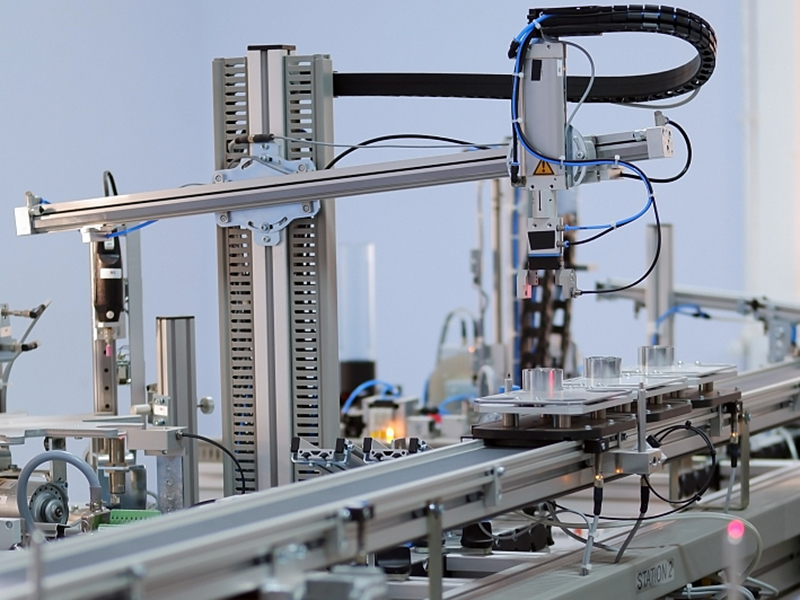

CNC machines automate some production steps, but others require human or robotic operators. Robots excel at tasks like loading materials, controlling processes, unloading parts, and conducting quality inspections. They improve efficiency, precision, and safety in tasks such as milling and welding.

ANY QUESTIONS FOR US?

Our experienced team will assist you and provide comprehensive solutions to your parts issues.

Please consult us today!