CNC Swiss Machining

Precision, Efficiency, and Quality - The Ultimate Solution for Complex and High-Volume Parts Production.

What is Swiss Machining?

Swiss machining is a manufacturing technique that offers specialized tool cutting designed to turn metal stock into complex, slender, or delicate components that require tight tolerances. Swiss machining generally refers to the Swiss-designed CNC-operated lathe that turns parts in a radial motion as it cuts the workpiece. The process is not only cost-effective, but it presents increased precision over other similar methods.

Where is Swiss Machining Used?

Swiss machining can produce small, intricate parts in high-volume for a number of industries, predominantly automotive, medical, defense, and electronics-related sectors. Swiss Machined PartsCNC Swiss-style machining has the capability to machine longer, slender, and more complex parts with incredible accuracy, efficiency, and throughput.

Automotive

CNC machining services are used to manufacture precise components for vehicles, such as engine parts and chassis components.

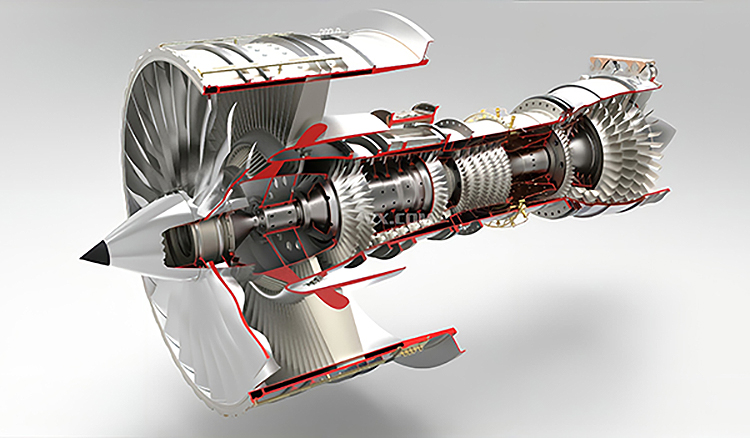

Aerospace

CNC machining services produce complex and critical components for the aerospace industry, including turbine blades and aircraft structural parts.

Consumer Goods

CNC machining services manufacture a wide range of consumer products with precise dimensions and high-quality finishes.

Medical Devices

CNC machining services produce intricate and accurate components for medical devices, such as surgical instruments and implants.

Electronics

CNC machining services produce precise components for electronics, such as circuit boards and connectors, with excellent electrical conductivity.

Swiss Lathe Capabilities

From small runs of a few hundred pieces up to hundreds of thousands, Swiss CNC machining allows designers to manufacture complex components on one machine. High-volume production runs with this machining can cover numerous processes, including, milling, threading, drilling, boring, turning, and other custom requirements. One machine can perform several operations at once in a shorter period of time while offering designers more control in the production of complex parts.

Swiss CNC machining can produce complex stainless steel parts from 0.030" to 2" in diameter parts. This allows designers to meet the unique specifications of even the most demanding applications.

Other metals, such as inconel, titanium, nickel and nickel-based alloys, can also be used to produce parts that require tight tolerances of ±0.0005 concentricity within 0.0001 inches.

Swiss machining allows micromachining of tiny parts that are more accurate, smaller and lighter - and faster. All of this allows Swiss machines to perform more complex machining operations than any other type of CNC machining system.

CNC Swiss machining with Kachi

Swiss machining is a fast, accurate, and cost-effective manufacturing method that’s ideal for creating large quantities of small parts that require complex CNC turning. However, as with any CNC process, it’s best to keep the above tips in mind when designing your parts to ensure your machining time and costs are as low as possible.

Whether Swiss machining is the ideal manufacturing process for your parts or traditional CNC turning is better-suited for your needs, working with an experienced manufacturing partner like Kachi can help you make the right decisions to get better quality parts faster. Start making the precision-machined parts you need today — contact us to get started or simply upload your part files to get an instant DFM analysis of your designs, explore material options, and to get a quote online.

Benefits of Swiss Machining

Originally designed for the watch-making industry, Swiss machines have exploded in popularity within precision manufacturing. This is because Swiss type lathes are uniquely capable of producing extremely small, precise parts at a rapid pace. The combination of high precision and high production volume make Swiss machines a critical piece of equipment for shops that must produce a large volume of small and intricate parts with little margin for error.

Key benefits of swiss machining include:

Kachi CNC Swiss Machining FAQS

CNC Swiss Machining can work with a wide range of materials, including stainless steel, titanium, aluminum, brass, copper, plastics, and more.

CNC Swiss Machining is ideal for producing small, complex parts with intricate geometries, such as medical implants, aerospace components, and electronics parts.

CNC Swiss Machining is unique in its ability to machine long, slender parts with high precision and accuracy. It also offers faster cycle times and reduced setup times compared to other machining processes.