Automotive development

The automotive industry is developing rapidly. As industry trends such as autonomous driving, in-vehicle connectivity, and hybrid/electric vehicles continue to drive innovation, some automotive components have become more demanding and sophisticated. With the help of rapid digital manufacturing and automated manufacturability feedback, designers and engineers can Reduce design and cost risk while developing a more responsive supply chain to better respond to driver and passenger demands for more customized vehicles.

Application development of new electric vehicle parts

Electric and autonomous vehicles are one of the most prosperous industries currently experiencing rapid growth. As a result, automotive companies are increasingly adapting their strategies and seeking specialized components to meet growing demand.

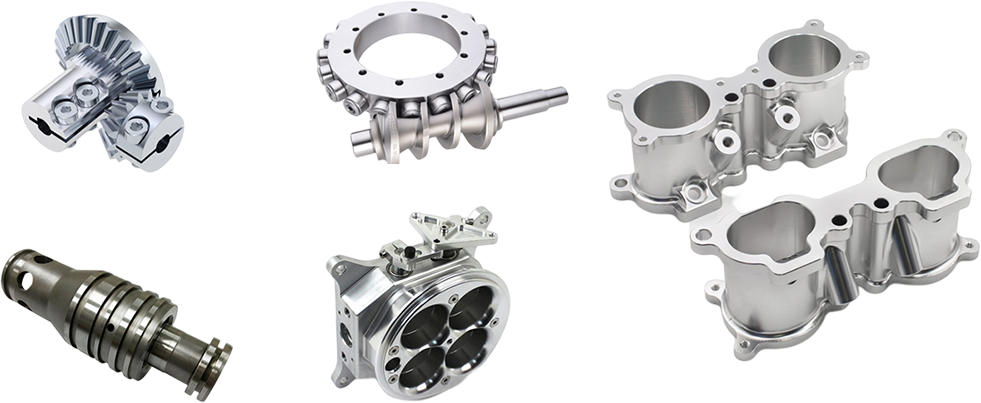

COMMON AUTOMOTIVE APPLICATIONS

Our advanced digital manufacturing capabilities expedite the production of various metal and plastic components for the automotive industry.

● Motor housing

● Battery cover

● Plastic Dashboard Components

● Window trim

● Chassis beam

● Automotive Consumer Electronics

Automotive Manufacturing Capabilities

CNC Machining

From our guarantee in cnc machining to providing custom machined parts that stand the test of time in durable medical grade metals including titanium, stainless steel, cobalt chrome and many copper alloys. It also helps you meet your production goals and accelerate the development of medical products.

Sheet Metal Fabrication

Sheet metal processing plays an important role in the medical field. Through sheet metal processing, various medical equipment and parts can be produced, such as housings, brackets, shields, etc. Sheet metal processing can perform precise cutting, bending, punching and welding processes according to design requirements to produce parts that meet medical device standards.

Surface Treatment

Different surface treatments can improve the corrosion resistance, wear resistance and aesthetics of medical devices. Common surface treatment methods include electroplating, anodizing, spraying, polishing and sandblasting, etc. These treatments can improve the quality and reliability of products, meet the requirements of regulations and standards, and enhance the market competitiveness of products.

Automotive Manufacturing Capabilities

CNC Machining

From our guarantee in cnc machining to providing custom machined parts that stand the test of time in durable medical grade metals including titanium, stainless steel, cobalt chrome and many copper alloys. It also helps you meet your production goals and accelerate the development of medical products.

Sheet Metal Fabrication

Sheet metal processing plays an important role in the medical field. Through sheet metal processing, various medical equipment and parts can be produced, such as housings, brackets, shields, etc. Sheet metal processing can perform precise cutting, bending, punching and welding processes according to design requirements to produce parts that meet medical device standards.

Surface Treatment

Different surface treatments can improve the corrosion resistance, wear resistance and aesthetics of medical devices. Common surface treatment methods include electroplating, anodizing, spraying, polishing and sandblasting, etc. These treatments can improve the quality and reliability of products, meet the requirements of regulations and standards, and enhance the market competitiveness of products.

Which materials are best suited for automotive applications?

Aluminum:

Aluminum alloy is widely used in automobile manufacturing because of its light weight, high strength and good thermal conductivity. For example, parts such as engine blocks, wheels and chassis are often CNC machined from aluminum alloy materials.

Carbon fiber composites:

Carbon fiber composites have excellent strength and stiffness, while being lightweight and corrosion-resistant. In automobile manufacturing, carbon fiber composites are often used to make parts such as body, roof and interior trim.

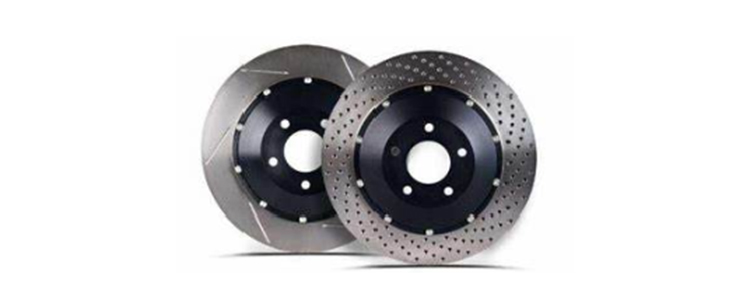

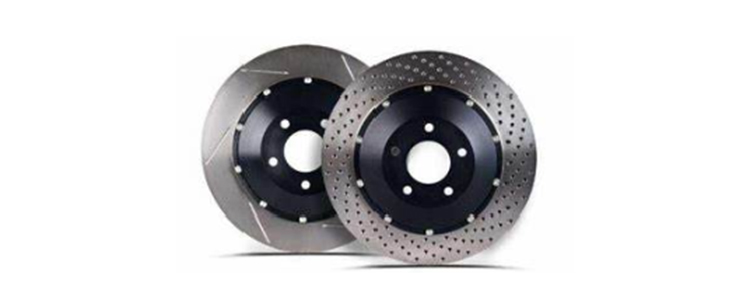

Steel:

Steel has high strength, wear resistance, and corrosion resistance, making it suitable for structural and component parts of automobiles. For example, key components such as body frames, drive trains and brake systems are often CNC machined from steel.

Plastics:

Plastics have good toughness, abrasion and chemical resistance, while being lightweight and low cost. In automobile manufacturing, plastics are commonly used in the manufacture of exterior body parts, interior trim and electrical components, among others.

Which materials are best suited for automotive applications?

Aluminum:

Aluminum alloy is widely used in automobile manufacturing because of its light weight, high strength and good thermal conductivity. For example, parts such as engine blocks, wheels and chassis are often CNC machined from aluminum alloy materials.

Carbon fiber composites:

Carbon fiber composites have excellent strength and stiffness, while being lightweight and corrosion-resistant. In automobile manufacturing, carbon fiber composites are often used to make parts such as body, roof and interior trim.

Steel:

Steel has high strength, wear resistance, and corrosion resistance, making it suitable for structural and component parts of automobiles. For example, key components such as body frames, drive trains and brake systems are often CNC machined from steel.

Plastics:

Plastics have good toughness, abrasion and chemical resistance, while being lightweight and low cost. In automobile manufacturing, plastics are commonly used in the manufacture of exterior body parts, interior trim and electrical components, among others.

Explore More Industries We Support

We have gained the necessary expertise and understanding to provide support across various industries.

To delve deeper into the industries we support, kindly click on the provided link.