The advantage of Metal Surface Finishing Process

The functions of metal surface treatment can be summarized as follows:

● Improve the appearance

● Add specific beautiful colors

● Change the luster

● Enhance chemical resistance

● Increase wear resistance

● Limit effects of corrosion

● Reduce friction

● Remove surface defects

● Cleaning the parts

● Serve as a primer coat

● Adjust the sizes

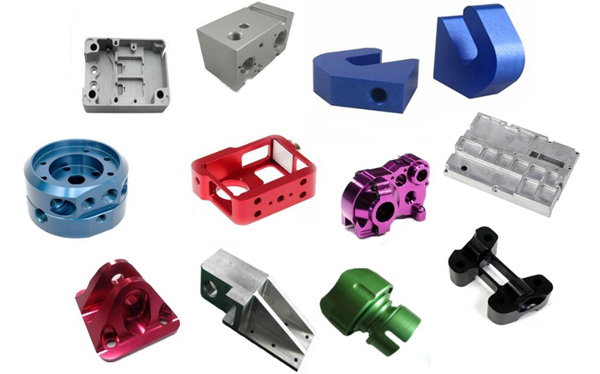

At Kachi, Our professional team of experts will advise on the ideal surface treatments and finishing techniques to achieve your desired results.You can select the best finish that strengthen and protect appearance of machined parts. The existing surface treatment processes include as below:

Anodize

Anodize is an electrolytic passivation process that grows the natural oxide layer on aluminum parts for protection from wear and corrosion, as well as for cosmetic effects.

Bead Blasting

Media blasting uses a pressurized jet of abrasive media to apply a matte, uniform finish to the surface of parts.

Electroplating

Nickel plating is a process used to electroplate a thin layer of nickel onto a metal part. This plating can be used for corrosion and wear resistance, as well as for decorative purposes.

Polishing

Custom CNC machining parts are manually polished in multiple directions. The surface is smooth and slightly reflective.

Chromate

Chromate treatments apply a chromium compound to a metal surface, giving the metal a corrosion-resistant finish. This type of surface finish can also give the metal a decorative appearance, and it’s an effective base for many types of paint. Not only that, but it also allows the metal to keep its electrical conductivity.

Painting

Painting involves spraying a layer of paint onto the surface of the part. Colors can be matched to a Pantone color number of the customer’s choosing, while finishes range from matte to gloss to metallic.

Black Oxide

Black oxide is a conversion coating similar to Alodine that is used for steel and stainless steel. It is used mainly for appearance and for mild corrosion resistance.

Part marking

Part marking is a cost-effective way to add logos or custom lettering to your designs and is often used for custom part tagging during full-scale production.

| Item | Available Surface Finishes | Function | Coating Appearance | Thickness | Standard | Suitable Material |

| 1 | Anodizing | Oxidation prevention, anti-friction, decorate figure | Clear, Black, Blue, Green, Gold, Red | 20-30μm | ISO7599, ISO8078, ISO8079 | Aluminium and its alloy |

| 2 | Hard Anodizing | Anti-oxidizing, Anti-stacic, increase abrasion resistance and surface hardness, decorating | Black | 30-40μm | ISO10074, BS/DIN 2536 | Aluminium and its alloy |

| 3 | Alodine | Increase corrosion resistance, enhance the surface structure and cleaness | Clear, colorless, iridescent yellow, brown, gray, or blue | 0.25-1.0μm | Mil-DTL-5541, MIL-DTL-81706, Mil-spec standards | Various Metal |

| 4 | Chrome Plating / Hard Chrome Plating | Corrosion resistance, increase surface hardness and abrasion resistance, Anti=rusty, decorating | Golden, Bright silver | 1-1.5μm Hard:8-12μm |

Specification SAE-AME-QQ-C-320, Class 2E | Aluminium and its alloy Steel and its alloy |

| 5 | Electroless Nickel Plating | Decoration, rust prevention, enhance hardness, corrosion resistance | Bright, light yellow | 3-5μm | MIL-C-26074, ASTM8733 AND AMS2404 | Various Metal, steel and Aluminium alloy |

| 6 | Zinc Plating | Anti-rusty, decorating, increase corrosion resistance | Blue, White, Red, Yellow, Black | 8-12μm | ISO/TR 20491, ASTM B695 | Varioius Metal |

| 7 | Gold / Silver Plating | Eletric and electro-magnetic wave conduction, decorating | Golder, Bright Silver | Golden:0.8-1.2μm Silver:7-12μm |

MIL-G-45204, ASTM B488, AMS 2422 | Steel and its alloy |

| 8 | Black Oxide | Anti-rusty, decorating | Black, Blue black | 0.5-1μm | ISO11408, MIL-DTL-13924, AMS2485 | Stainless Steel, Chromium Steel |

| 9 | Powder Paint /Painting | corrosion resistance, decorating | Black or any Ral code or Pantone number | 2-72μm | Different company standard | Various metal |

| 10 | Passivation of Stainless Steel | Anti-rusty, decorating | No alernation | 0.3-0.6μm | ASTM A967, AMS2700&QQ-P-35 | Stainless Steel |

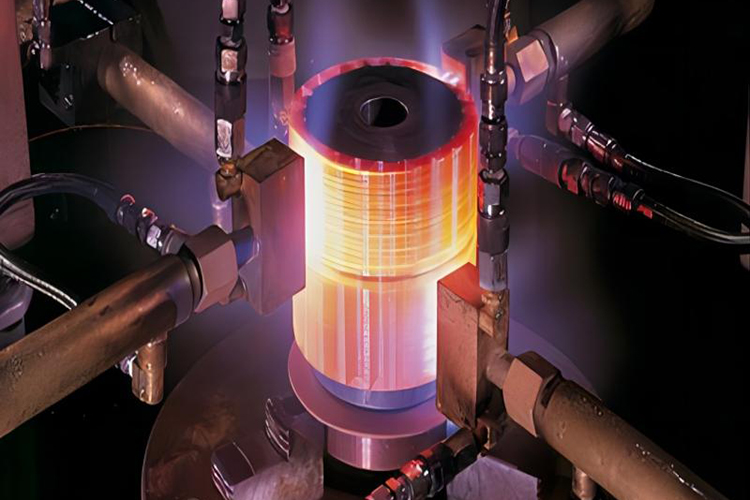

Heat Treating

Heat treatment is an essential step in precision machining. However, there is more than one way to accomplish it, and your choice of heat treatment depends on materials, industry and final application.

Heat Treating Services

Heat treating metalHeat treating is the process by which a metal is heated or cooled in a tightly controlled environment to manipulate physical properties such as its malleability, durability, fabricability, hardness, and strength. Heat-treated metals are imperative to many industries including the aerospace, automotive, computer, and heavy equipment industries. Heat treating metal parts (such as screws or engine brackets) creates value by improving their versatility and applicability.

Heat treatment is a three-step process. First, the metal is heated to the specific temperature needed to bring about the desired change. Next, the temperature is maintained until the metal has been evenly heated. The heat source is then removed, allowing the metal to cool completely.

Steel is the most common heat treated metal but this process is performed on other materials:

● Aluminum

● Brass

● Bronze

● Cast Iron

● Copper

● Hastelloy

● Inconel

● Nickel

● Plastic

● Stainless Steel

The Different Heat Treatment Options

Hardening: Hardening is performed to address metal’s deficiencies, especially those that affect overall durability. It is performed by heating the metal and quenching it quickly right when it reaches the desired properties. This freezes the particles so it gains new qualities.

Hardening: Hardening is performed to address metal’s deficiencies, especially those that affect overall durability. It is performed by heating the metal and quenching it quickly right when it reaches the desired properties. This freezes the particles so it gains new qualities.

Annealing: Most common with aluminum, copper, steel, silver or brass, annealing involves heating metal to a high temperature, holding it there and allowing it to slowly cool. This makes these metals easier to work into shape. Copper, silver and brass can be cooled quickly or slowly, depending on the application, but steel must always cool slowly or it will not anneal properly. This is normally accomplished before machining so materials do not fail during manufacturing.

Normalizing: Often used on steel, normalizing improves machinability, ductility and strength. Steel heats to 150 to 200 degrees hotter than metals used in annealing processes and is held there until the desired transformation occurs. The process requires steel to air cool in order to create refined ferritic grains. This is also useful for removing columnar grains and dendritic segregation, which can compromise quality while casting a part.

Tempering: This process is used for iron-based alloys, especially steel. These alloys are extremely hard, but often too brittle for their intended purposes. Tempering heats metal to a temperature just below the critical point, as this will reduce the brittleness without compromising the hardness. If a customer wishes for better plasticity with less hardness and strength, we heat metal to a higher temperature. Sometimes, though, materials are resistant to tempering, and it may be easier to purchase material that is already hardened or to harden it before machining.

Case hardening: If you need a hard surface but a softer core, case hardening is your best bet. This is a common process for metals with less carbon, like iron and steel. In this method, heat treatment adds carbon to the surface. You will normally order this service after pieces are machined so you can make them extra durable. It is performed by using high heat with other chemicals, as that reduces the risk of making the part brittle.

Aging: Also known as precipitation hardening, this process increases the yield strength of softer metals. If metal requires additional hardening beyond its current structure, precipitation hardening adds impurities to increase strength. This process usually happens after other methods were used, and it only raises temperatures to middle levels and cools material quickly. If a technician decides natural aging is best, materials are stored in cooler temperatures until they reach the desired properties.