Inzuzo ye-Metal Surface Finishing Process

Imisebenzi yokwelashwa kwendawo yensimbi ingafingqwa ngale ndlela elandelayo:

● Thuthukisa ukubukeka

● Engeza imibala ethile emihle

● Shintsha ukubenyezela

● Thuthukisa ukumelana namakhemikhali

● Khulisa ukumelana nokuguga

● Nciphisa imiphumela yokugqwala

● Nciphisa ukungqubuzana

● Susa ukonakala kwendawo

● Ukuhlanza izingxenye

● Khonza njengejazi lokuqala

● Lungisa osayizi

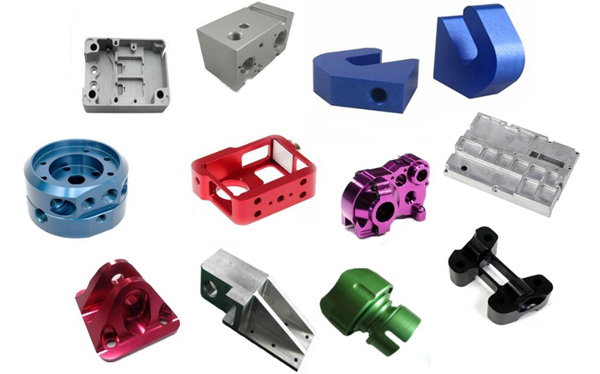

Kwa-Kachi, ithimba lethu lochwepheshe lizokweluleka mayelana nezindlela zokwelapha ezisezingeni eliphezulu nezindlela zokuqeda ukuze uzuze imiphumela oyifunayo.Ungakhetha isiphetho esihle kakhulu esiqinisa futhi sivikele ukubukeka kwezingxenye eziwumshini.Izinqubo zokwelashwa ezikhona zifaka lokhu okulandelayo:

Anodize

I-Anodize iyinqubo ye-electrolytic passivation ekhulisa ungqimba lwemvelo lwe-oxide ezingxenyeni ze-aluminium ukuze luvikeleke ekugugeni nasekugqwaleni, kanye nemiphumela yezimonyo.

Ukuqhunyiswa kobuhlalu

Ukuqhuma kwemidiya kusebenzisa ijethi ecindezelweyo yemidiya elumayo ukuze kufakwe isiphetho se-matte, esifanayo ebusweni bezingxenye.

I-Electroplating

I-Nickel Plating iyinqubo esetshenziselwa ukufaka ungqimba oluncane lwe-nickel engxenyeni yensimbi.Le plating ingasetshenziselwa ukugqwala nokumelana nokugqoka, kanye nezinjongo zokuhlobisa.

Ukupholisha

Izingxenye zokwenza ngokwezifiso ze-CNC zipholishwa ngesandla ngezindlela eziningi.Ingaphezulu libushelelezi futhi liyabonisa kancane.

I-Chromate

Ukwelashwa kwe-chromate kusebenzisa inhlanganisela ye-chromium endaweni yensimbi, okunikeza insimbi isiphetho esimelana nokugqwala.Lolu hlobo lokuqedwa kwendawo lungaphinda lunikeze insimbi ukubukeka kokuhlobisa, futhi kuyisisekelo esisebenzayo sezinhlobo eziningi zopende.Akukhona lokho kuphela, kodwa futhi kuvumela insimbi ukuthi igcine ukuqhutshwa kwayo kagesi.

Ukudweba

Ukudweba kuhilela ukufafaza ungqimba lukapende phezu kwengxenye.Imibala ingafaniswa nenombolo yombala we-Pantone oyikhethayo ikhasimende, kuyilapho ukuqedwa kuhluka ukusuka ku-matte kuye kokucwebezelayo kuye kwensimbi.

I-Black oxide

I-Black oxide iyinalethi yokuguqula efana ne-Alodine esetshenziselwa insimbi nensimbi engagqwali.Isetshenziselwa ikakhulukazi ukubukeka kanye nokumelana nokugqwala okuncane.

Ukumaka ingxenye

Ukumaka ingxenye kuyindlela engabizi kakhulu yokwengeza amalogo noma amagama angokwezifiso emiklamo yakho futhi kuvame ukusetshenziselwa ukumaka ingxenye yangokwezifiso phakathi nokukhiqizwa kwesilinganiso esigcwele.

| Into | I-Surface Finishes etholakalayo | Umsebenzi | Ukubukeka kwe-Coating | Ubukhulu | Okujwayelekile | Impahla Efanelekayo |

| 1 | I-anodizing | Ukuvimbela i-oxidation, anti-friction, ukuhlobisa isibalo | Okucacile, Okumnyama, Okuluhlaza okwesibhakabhaka, Okuhlaza, Okusagolide, Okubomvu | 20-30μm | ISO7599, ISO8078, ISO8079 | I-aluminium kanye ne-alloy yayo |

| 2 | I-Anodizing enzima | I-Anti-oxidizing, i-Anti-stacic, ikhulisa ukumelana nemihuzuko kanye nobulukhuni bobuso, ukuhlobisa | Mnyama | 30-40μm | ISO10074, BS/DIN 2536 | I-aluminium kanye ne-alloy yayo |

| 3 | I-Alodine | Khulisa ukumelana nokugqwala, uthuthukise ukwakheka kwendawo kanye nokuhlanzeka | Icacile, ayinambala, iphuzi, insundu, impunga, noma eluhlaza okwesibhakabhaka | 0.25-1.0μm | Mil-DTL-5541, MIL-DTL-81706, Mil-spec amazinga | I-Metal Ehlukahlukene |

| 4 | I-Chrome Plating / Hard Chrome Plating | Ukumelana nokugqwala, kwandisa ubulukhuni bobuso kanye nokumelana nokuhuzuka, Anti=ukugqwala, ukuhlobisa | Igolide, Isiliva Elikhanyayo | 1-1.5μm Ukuqina: 8-12μm | Ukucaciswa kwe-SAE-AME-QQ-C-320, Ikilasi 2E | I-aluminium kanye ne-alloy yayo Insimbi kanye nengxubevange yayo |

| 5 | I-Electroless Nickel Plating | Ukuhlobisa, ukuvimbela ukugqwala, ukuthuthukisa ubulukhuni, ukumelana nokugqwala | Okukhanyayo, okuphuzi okukhanyayo | 3-5μm | I-MIL-C-26074, ASTM8733 KANYE NE-AMS2404 | Ingxubevange ye-Metal, insimbi ne-Aluminium |

| 6 | I-Zinc Plating | I-Anti-rusty, ukuhlobisa, ukwandisa ukumelana nokugqwala | Okuluhlaza okwesibhakabhaka, Okumhlophe, Okubomvu, Okuphuzi, Okumnyama | 8-12μm | ISO/TR 20491, ASTM B695 | I-Various Metal |

| 7 | Igolide / Isiliva Plating | Eletric and electro-magnetic wave conduction, ukuhlobisa | Igolide, Isiliva Elikhanyayo | Igolide: 0.8-1.2μm Isiliva: 7-12μm | I-MIL-G-45204, ASTM B488, AMS 2422 | Insimbi kanye nengxubevange yayo |

| 8 | I-Black oxide | I-Anti-rusty, ukuhlobisa | Black, Blue black | 0.5-1μm | ISO11408, MIL-DTL-13924, AMS2485 | Insimbi Engagqwali, Insimbi Ye-Chromium |

| 9 | I-Powder Paint / Painting | ukumelana nokugqwala, ukuhlobisa | Mnyama noma iyiphi inombolo ye-Ral noma inombolo yePantoni | 2-72μm | Izinga lenkampani elihlukile | Insimbi ehlukahlukene |

| 10 | Passivation of Stainless Steel | I-Anti-rusty, ukuhlobisa | Akukho ukuxwayisa | 0.3-0.6μm | I-ASTM A967, AMS2700&QQ-P-35 | Insimbi engagqwali |

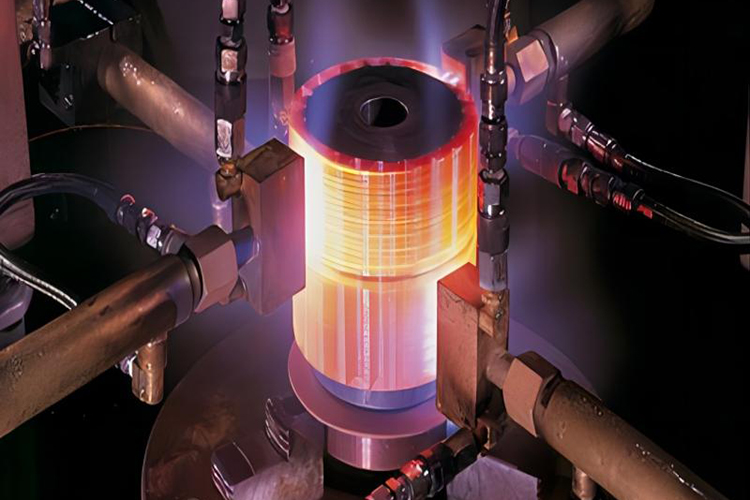

Ukwelapha Ukushisa

Ukwelashwa kokushisa kuyisinyathelo esibalulekile ekwenzeni imishini enembile.Kodwa-ke, kunezindlela ezingaphezu kweyodwa zokukufeza, futhi ukukhetha kwakho ukwelashwa kokushisa kuncike ezintweni, imboni kanye nesicelo sokugcina.

Amasevisi Okwelapha Ukushisa

Ukwelapha i-metalHeat Ukwelashwa kokushisa kuyinqubo lapho insimbi ifudumeza noma ipholiswa khona endaweni elawulwa ngokuqinile ukuze ilawule izinto ezibonakalayo ezifana nokusebenziseka kwayo kalula, ukuqina, ukwenziwa, ubulukhuni, namandla.Izinsimbi ezifakwe ukushisa zibalulekile ezimbonini eziningi ezihlanganisa i-aerospace, izimoto, ikhompyutha, nezimboni zemishini esindayo.Ukushisa izingxenye zensimbi (njengezikulufu noma abakaki benjini) kudala inani ngokuthuthukisa ukuhlukahluka kwazo nokusebenza kwazo.

Ukwelashwa kokushisa kuyisinyathelo esinezinyathelo ezintathu.Okokuqala, insimbi iyashiselwa ezingeni lokushisa elithile elidingekayo ukuze ilethe ushintsho olufunayo.Okulandelayo, izinga lokushisa liyagcinwa kuze kube yilapho insimbi isishiswe ngokulinganayo.Umthombo wokushisa ube usukhishwa, okuvumela insimbi ukuthi iphole ngokuphelele.

Insimbi iyinsimbi evamile ephathwa ngokushisa kodwa le nqubo yenziwa kwezinye izinto:

● I-Aluminium

● Ithusi

● Ithusi

● Insimbi Yokuphonsa

● Ithusi

● I-Hastelloy

● Khipha

● Nickel

● Ipulasitiki

● Insimbi Engagqwali

Izinketho Ezihlukene Zokwelapha Ukushisa

Ukuqina:Ukuqina kwenziwa ukuze kubhekwane nokusilela kwensimbi, ikakhulukazi lokho okuthinta ukuqina kukonke.Yenziwa ngokushisisa insimbi futhi iyicime ngokushesha lapho ifika ezindaweni ezifunwayo.Lokhu kumisa izinhlayiya ukuze kuzuze izimfanelo ezintsha.

Ukuqina:Ukuqina kwenziwa ukuze kubhekwane nokusilela kwensimbi, ikakhulukazi lokho okuthinta ukuqina kukonke.Yenziwa ngokushisisa insimbi futhi iyicime ngokushesha lapho ifika ezindaweni ezifunwayo.Lokhu kumisa izinhlayiya ukuze kuzuze izimfanelo ezintsha.

I-Annealing:Okuvame kakhulu nge-aluminium, ithusi, insimbi, isiliva noma ithusi, i-annealing ihilela ukushisa insimbi ekushiseni okuphezulu, ukuyibamba lapho bese uyivumela ukuthi iphole kancane.Lokhu kwenza lezi zinsimbi zibe lula ukusebenza zibe yisimo.Ithusi, isiliva kanye nethusi kungapholiswa ngokushesha noma kancane, kuye ngokufakwa, kodwa insimbi kufanele ihlale ipholile kancane noma ngeke ikwazi ukudonsa kahle.Lokhu kuvame ukufezwa ngaphambi komshini ukuze izinto zokwakha zingahluleki ngesikhathi sokukhiqiza.

Ukujwayela:Ngokuvamile esetshenziswa ensimbi, normalizing ngcono machinability, ductility namandla.Insimbi ishisa ifike ku-150 kuya ku-200 degrees ukushisa kunezinsimbi ezisetshenziswa ezinqubweni zokudonsa amanzi futhi ibanjelwa lapho kuze kube yilapho kwenzeka uguquko olufunekayo.Inqubo idinga insimbi ukuze iphole ukuze idale izinhlamvu ezicolisisiwe ze-ferritic.Lokhu futhi kuyasiza ekususeni okusanhlamvu kwe-columnar nokuhlukaniswa kwe-dendritic, okungafaka engozini ikhwalithi ngenkathi kukhishwa ingxenye.

Ukufudumala:Le nqubo isetshenziselwa ama-alloys asekelwe ensimbi, ikakhulukazi insimbi.Lawa ma-alloys aqinile ngokwedlulele, kodwa avame ukuba brittle ngokwezinjongo zawo ezihlosiwe.I-Tempering ishisa insimbi ekushiseni okungaphansi nje kwephuzu elibalulekile, njengoba lokhu kuzonciphisa ukuqina ngaphandle kokubeka engcupheni ubulukhuni.Uma ikhasimende lifisa ipulasitiki engcono enobulukhuni obuncane namandla, sishisisa insimbi ibe izinga lokushisa eliphezulu.Nokho, ngezinye izikhathi izinto zokwakha azikwazi ukushiswa, futhi kungase kube lula ukuthenga izinto eseziqinile kakade noma ukuzenza lukhuni ngaphambi komshini.

Ukuqina kwekesi: Uma udinga indawo eqinile kodwa ingqikithi ethambile, ukuqina kwekesi kungukubheja kwakho okuhle kakhulu.Lena inqubo evamile yezinsimbi ezinekhabhoni encane, njengensimbi nensimbi.Ngale ndlela, ukwelashwa kokushisa kwengeza i-carbon ebusweni.Ngokuvamile uzo-oda le sevisi ngemva komshini wezingcezu ukuze uzenze ziqine ngokwengeziwe.Kwenziwa ngokusebenzisa ukushisa okuphezulu namanye amakhemikhali, njengoba lokho kunciphisa ingozi yokwenza ingxenye ibe brittle.

Ukuguga:Eyaziwa nangokuthi ukuqina kwemvula, le nqubo inyusa amandla okukhiqiza ezinsimbi ezithambile.Uma insimbi idinga ukuqina okwengeziwe okungaphezu kwesakhiwo sayo samanje, ukuqina kwemvula kunezela ukungcola ukuze kwandiswe amandla.Le nqubo ivamise ukwenzeka ngemva kokusetshenziswa ezinye izindlela, futhi inyusa amazinga okushisa kuphela aye emazingeni aphakathi nendawo futhi ipholise impahla ngokushesha.Uma uchwepheshe enquma ukuthi ukuguga kwemvelo kungcono kakhulu, izinto ezisetshenziswayo zigcinwa emazingeni okushisa apholile zize zifinyelele izici ezifunwayo.