Molemo oa Metal Surface Finishing Process

Mesebetsi ea phekolo ea holim'a tšepe e ka akaretsoa ka tsela e latelang:

● Ntlafatsa ponahalo

● Eketsa mebala e metle ka ho khetheha

● Fetola khanya

● Ntlafatsa khanyetso ea lik'hemik'hale

● Eketsa khanyetso ea ho apara

● Fokotsa liphello tsa ho bola

● Fokotsa likhohlano

● Tlosa mefokolo e ka holimo

● Ho hloekisa likarolo

● Sebeletsa e le seaparo sa pele

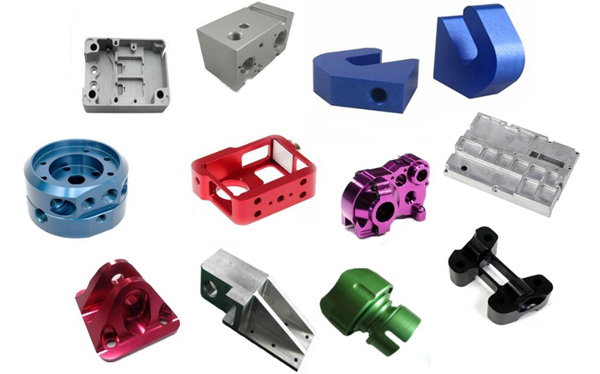

● Fetola boholo

Kachi, sehlopha sa rona sa litsebi sa litsebi se tla eletsa ka mekhoa e metle ea phekolo ea holim'a metsi le mekhoa ea ho qeta ho finyella liphello tsa hau tse lakatsehang. U ka khetha qetello e ntle ka ho fetisisa e matlafatsang le ho sireletsa ponahalo ea likarolo tse entsoeng ka mochine.Mekhoa e teng ea kalafo ea holim'a metsi e kenyelletsa tse latelang:

Anodize

Anodize ke ts'ebetso ea electrolytic passivation e holisang lesela la oxide ea tlhaho likarolong tsa aluminium bakeng sa ts'ireletso khahlanong le ho senyeha le ho bola, hammoho le litlamorao tsa litlolo.

Ho phatloha ha Bead

Ho phatloha ha mecha ea litaba ho sebelisa jete e hatelletsoeng ea mecha ea phatlalatso ea abrasive ho kenya matte, seaparo se tšoanang holim'a likarolo.

Electroplating

Nickel plating ke mokhoa o sebelisetsoang ho electroplate lesela le tšesaane la nickel holim'a karolo ea tšepe.Plating ena e ka sebelisoa bakeng sa kutu le ho hanyetsa ho roala, hammoho le merero ea ho khabisa.

Ho benya

Likarolo tsa mochini oa CNC tse tloahelehileng li bentšoa ka letsoho ka mahlakoreng a mangata.Bokaholimo bo boreleli ebile boa khantša hanyane.

Chromate

Kalafo ea chromate e sebelisa motsoako oa chromium sebakeng sa tšepe, e leng se fanang ka tšepe ea ho qetela e thibelang ho bola.Mofuta ona oa ho qeta holimo o ka boela oa fa tšepe ponahalo ea mokhabiso, 'me ke motheo o atlehang oa mefuta e mengata ea pente.Hase feela hoo, empa hape e lumella tšepe ho boloka motlakase oa eona oa motlakase.

Ho penta

Ho penta ho kenyelletsa ho fafatsa lera la pente holim'a karolo eo.Mebala e ka tsamaellana le nomoro ea 'mala oa Pantone eo moreki a e khethang, ha lipheletso li fapana ho tloha ho matte ho isa ho gloss ho isa ho metallic.

Black oxide

Black oxide ke seaparo sa phetoho se tšoanang le Alodine se sebelisetsoang tšepe le tšepe e sa hloekang.E sebelisoa haholo-holo bakeng sa ponahalo le bakeng sa khanyetso e fokolang ea kutu.

Ho tšoaea karolo

Ho tšoaea karolo ke mokhoa o sa jeng chelete e ngata oa ho kenya li-logo kapa litlhaku tse tloahelehileng ho meralo ea hau, 'me hangata e sebelisoa bakeng sa ho tšoaea karolo e ikhethileng nakong ea tlhahiso e felletseng.

| Ntho | E Fumaneha Surface Finishes | Mosebetsi | Coating Ponahalo | Botenya | Standard | Boitsebiso bo Loketseng |

| 1 | Anodizing | Thibelo ea oxidation, anti-friction, khabisa setšoantšo | Ho hlakile, Botsho, Boputswa, Botala, Khauta, Bofubedu | 20-30μm | ISO7599, ISO8078, ISO8079 | Aluminium le motsoako oa eona |

| 2 | Anodizing e thata | Anti-oxidizing, Anti-stacic, eketsa khanyetso ea abrasion le ho thatafala holimo, ho khabisa | Ntsho | 30-40μm | ISO10074, BS/DIN 2536 | Aluminium le motsoako oa eona |

| 3 | Alodine | Eketsa khanyetso ea kutu, ntlafatsa sebopeho sa bokaholimo le bohloeki | E hlakile, ha e na 'mala, e 'mala o mosehla, o sootho, o moputsoa kapa o moputsoa | 0.25-1.0μm | Mil-DTL-5541, MIL-DTL-81706, Mil-spec litekanyetso | Mefuta e sa tšoaneng ea Metal |

| 4 | Chrome Plating / Hard Chrome Plating | Ho hanyetsa ha kutu, ho eketsa ho thatafala ha bokaholimo le ho haneloa ke mafome, Anti=rusty, ho khabisa | Khauta, silevera e khanyang | 1-1.5μm E thata: 8-12μm | Tlhaloso SAE-AME-QQ-C-320, Sehlopha sa 2E | Aluminium le motsoako oa eona Tšepe le motsoako oa eona |

| 5 | Electroless Nickel Plating | Mokhabiso, thibelo ea mafome, ho matlafatsa ho thatafala, ho hanyetsa kutu | E khanyang, e mosehla o khanyang | 3-5μm | MIL-C-26074, ASTM8733 LE AMS2404 | Mefuta e fapaneng ea tšepe, tšepe le Aluminium alloy |

| 6 | Ho roala Zinc | Anti-rusty, mokhabiso, eketsa khanyetso ea kutu | Boputsoa, Bosoeu, Bokhubelu, Bosehla, Botsho | 8-12μm | ISO/TR 20491, ASTM B695 | Mefuta e sa tšoaneng ea Metal |

| 7 | Khauta / Silver Plating | Eletric le electromagnetic wave conduction, mokhabiso | Khauta, Silivera e Khanyang | Khauta: 0.8-1.2μm Silevera: 7-12μm | MIL-G-45204, ASTM B488, AMS 2422 | Tšepe le motsoako oa eona |

| 8 | Black oxide | Anti-rusty, mokhabiso | Botsho, Boputswa botsho | 0.5-1μm | ISO11408, MIL-DTL-13924, AMS2485 | Tšepe e se nang Mokelikeli, Tšepe ea Chromium |

| 9 | Pente ea phofo / Penta | ho hanyetsa kutu, ho khabisa | Ntsho kapa nomoro efe kapa efe ya Ral kapa nomoro ya Pantone | 2-72μm | Tekanyetso e fapaneng ea k'hamphani | Mefuta e fapaneng ea tšepe |

| 10 | Passivation of Stainless Steel | Anti-rusty, mokhabiso | Ha ho tlhokomeliso | 0.3-0.6μm | ASTM A967, AMS2700&QQ-P-35 | Ts'epe e sa beng le mabali |

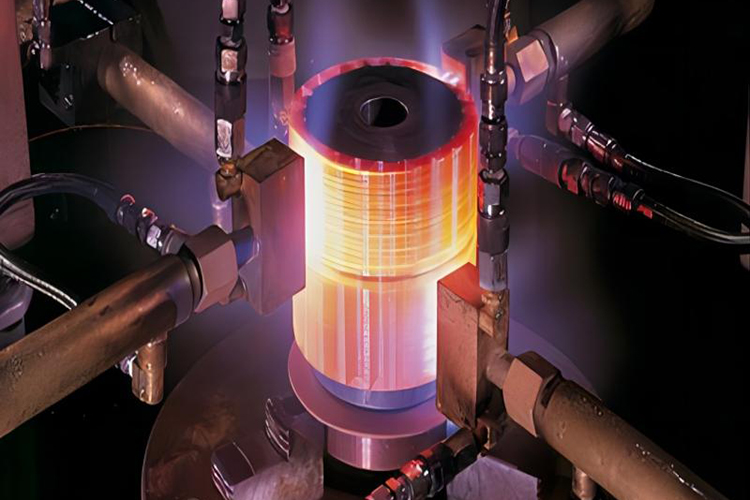

Phekolo ea Mocheso

Phekolo ea mocheso ke mohato oa bohlokoa oa ho sebetsa ka nepo.Leha ho le joalo, ho na le mekhoa e fetang e le 'ngoe ea ho e finyella,' me khetho ea hau ea phekolo ea mocheso e itšetlehile ka thepa, indasteri le kopo ea ho qetela.

Litšebeletso tsa Phekolo ea Mocheso

Phekolo ea mocheso ea metalHeat ke mokhoa oo tšepe e futhumatsang kapa e pholileng sebakeng se laoloang ka thata ho laola thepa ea 'mele e kang ho senyeha ha eona, ho tšoarella, ho sebetsa, ho thatafala le matla.Litšepe tse hloekisitsoeng mocheso li bohlokoa liindastering tse ngata ho kenyeletsoa liindasteri tsa sefofane, likoloi, likhomphutha le lisebelisoa tse boima.Likarolo tsa tšepe tse hloekisang mocheso (joalo ka likurufu kapa libakakete tsa enjine) li etsa boleng ka ho ntlafatsa maemo a tsona a fapaneng le ho sebetsa.

Phekolo ea mocheso ke mehato e meraro.Ntlha ea pele, tšepe e futhumatsoa ho ea mocheso o khethehileng o hlokahalang ho tlisa phetoho e lakatsehang.Ka mor'a moo, mocheso o bolokoa ho fihlela tšepe e futhumetse ka ho lekana.Joale mohloli oa mocheso o tlosoa, ho lumella tšepe hore e pholile ka ho feletseng.

Tšepe ke tšepe e sebelisoang haholo ho phekola mocheso empa ts'ebetso ena e etsoa ho lisebelisoa tse ling:

● Aluminium

● Koporo

● Boronse

● Beha Tšepe

● Koporo

● Hastelloy

● Innele

● Nickel

● Plastiki

● Tšepe e Hloekileng

Likhetho tse fapaneng tsa Phekolo ea Mocheso

Ho thatafatsa:Ho thatafala ho etsoa ho sebetsana le mefokolo ea tšepe, haholo-holo e amang ho tšoarella ka kakaretso.E etsoa ka ho futhumatsa tšepe le ho e tima ka potlako hantle ha e fihla thepa e lakatsehang.Sena se homisa likaroloana e le hore se fumane litšobotsi tse ncha.

Ho thatafatsa:Ho thatafala ho etsoa ho sebetsana le mefokolo ea tšepe, haholo-holo e amang ho tšoarella ka kakaretso.E etsoa ka ho futhumatsa tšepe le ho e tima ka potlako hantle ha e fihla thepa e lakatsehang.Sena se homisa likaroloana e le hore se fumane litšobotsi tse ncha.

Ho tlatsa:E tloaelehileng ka ho fetisisa ka aluminium, koporo, tšepe, silevera kapa koporo, annealing e kenyelletsa ho futhumatsa tšepe ho mocheso o phahameng, ho e tšoara moo le ho e lumella hore e pholile butle-butle.Sena se etsa hore litšepe tsena ho be bonolo ho sebetsa ka sebopeho.Koporo, silevera le koporo li ka folisoa kapele kapa butle, ho latela ts'ebeliso, empa tšepe e tlameha ho lula e pholile butle kapa e ke ke ea khangoa hantle.Hangata sena se etsoa pele ho etsoa machining e le hore lisebelisoa li se ke tsa hloleha nakong ea tlhahiso.

Ho tloaeleha:Hangata e sebelisoa ka tšepe, ho tloaeleha ho ntlafatsa machinability, ductility le matla.Tšepe e futhumala ho likhato tse 150 ho isa ho tse 200 ho feta litšepe tse sebelisoang mekhoeng ea ho anela 'me e tšoareloa moo ho fihlela phetoho e lakatsehang e etsahala.Ts'ebetso e hloka hore tšepe e pholile moeeng e le ho etsa lithollo tse hloekisitsoeng tsa ferritic.Sena se boetse se na le thuso bakeng sa ho tlosa lithollo tsa columnar le karohano ea dendritic, e ka senyang boleng ha e ntse e lahla karolo.

Ho futhumatsa:Mokhoa ona o sebelisoa bakeng sa li-alloys tse entsoeng ka tšepe, haholo-holo tšepe.Li-alloys tsena li thata haholo, empa hangata li brittle bakeng sa merero ea tsona.Ho futhumatsa tšepe ho mocheso ka tlase ho ntlha e mahlonoko, kaha sena se tla fokotsa brittleness ntle le ho sekisetsa ho thatafala.Haeba moreki a lakatsa ho ba le polasetiki e ntlafetseng ka thata le matla a fokolang, re futhumatsa tšepe ho mocheso o phahameng.Leha ho le joalo, ka linako tse ling thepa ha e kokobele, ’me ho ka ’na ha e-ba bonolo ho reka thepa e seng e thatafalitsoe kapa ho e thatafatsa pele ho etsoa mochine.

Ho thatafatsa nyeoe: Haeba u hloka sebaka se thata empa se le bonolo, ho thatafatsa kesi ke bethe ea hau e ntle ka ho fetisisa.Ena ke mokhoa o tloaelehileng oa litšepe tse nang le carbon e nyenyane, joalo ka tšepe le tšepe.Ka mokhoa ona, phekolo ea mocheso e eketsa carbon holim'a metsi.Ka tloaelo u tla odara ts'ebeletso ena ka mor'a hore likotoana li entsoe ka mochini e le hore u ka li etsa hore li tšoarelle nako e telele.E etsoa ka ho sebelisa mocheso o phahameng ka lik'hemik'hale tse ling, kaha seo se fokotsa kotsi ea ho etsa hore karolo e brittle.

Botsofali:E boetse e tsejoa e le ho thatafala ha pula, ts'ebetso ena e eketsa matla a tlhahiso ea litšepe tse bonolo.Haeba tšepe e hloka ho thatafala ho feta sebopeho sa eona sa hajoale, ho thatafala ha pula ho eketsa litšila ho eketsa matla.Ts'ebetso ena hangata e etsahala ka mor'a hore ho sebelisoe mekhoa e meng, 'me e nyolla mocheso ho fihla maemong a bohareng le ho pholisa lintho kapele.Haeba setsebi se etsa qeto ea hore botsofali ba tlhaho bo molemo ka ho fetisisa, lisebelisoa li bolokoa mochesong o pholileng ho fihlela li fihla linthong tse lakatsehang.