Phekolo ea Mocheso

Phekolo ea mocheso ke mohato oa bohlokoa oa ho sebetsa ka nepo.Leha ho le joalo, ho na le mekhoa e fetang e le 'ngoe ea ho e finyella,' me khetho ea hau ea phekolo ea mocheso e itšetlehile ka thepa, indasteri le kopo ea ho qetela.

Litšebeletso tsa Phekolo ea Mocheso

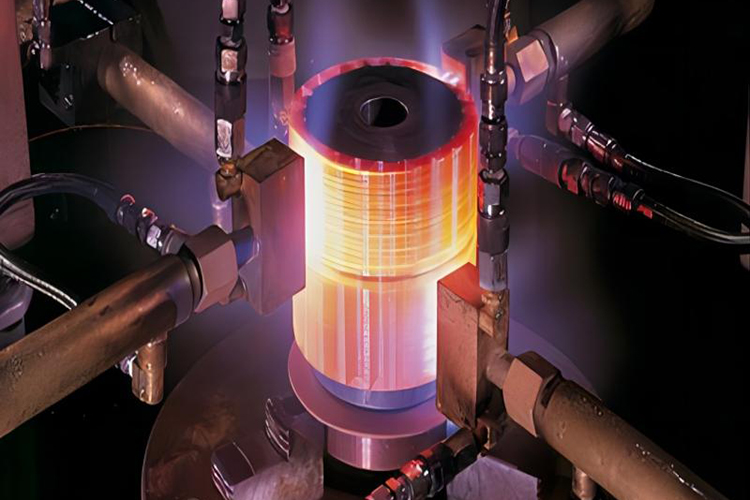

Phekolo ea mocheso ea metalHeat ke mokhoa oo tšepe e futhumatsang kapa e pholileng sebakeng se laoloang ka thata ho laola thepa ea 'mele e kang ho senyeha ha eona, ho tšoarella, ho sebetsa, ho thatafala le matla.Litšepe tse hloekisitsoeng mocheso li bohlokoa liindastering tse ngata ho kenyeletsoa liindasteri tsa sefofane, likoloi, likhomphutha le lisebelisoa tse boima.Likarolo tsa tšepe tse hloekisang mocheso (joalo ka likurufu kapa libakakete tsa enjine) li etsa boleng ka ho ntlafatsa maemo a tsona a fapaneng le ho sebetsa.

Phekolo ea mocheso ke mehato e meraro.Ntlha ea pele, tšepe e futhumatsoa ho ea mocheso o khethehileng o hlokahalang ho tlisa phetoho e lakatsehang.Ka mor'a moo, mocheso o bolokoa ho fihlela tšepe e futhumetse ka ho lekana.Joale mohloli oa mocheso o tlosoa, ho lumella tšepe hore e pholile ka ho feletseng.

Tšepe ke tšepe e sebelisoang haholo ho phekola mocheso empa ts'ebetso ena e etsoa ho lisebelisoa tse ling:

● Aluminium

● Koporo

● Boronse

● Beha Tšepe

● Koporo

● Hastelloy

● Innele

● Nickel

● Plastiki

● Tšepe e Hloekileng