Maganin Zafi

Maganin zafi muhimmin mataki ne a cikin ingantattun injina.Duk da haka, akwai fiye da hanya ɗaya don cika shi, kuma zaɓinku na maganin zafi ya dogara da kayan aiki, masana'antu da aikace-aikace na ƙarshe.

Ayyukan Maganin Zafi

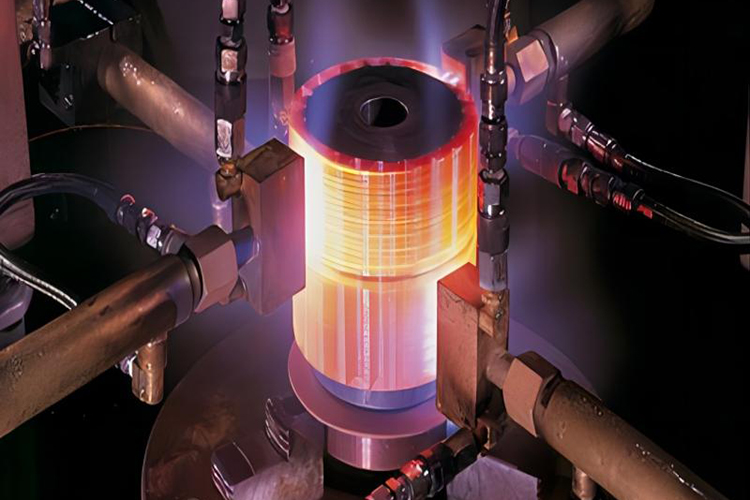

Maganin zafi mai zafi shine tsarin da ƙarfe ke yin zafi ko sanyaya a cikin yanayi mai ƙarfi don sarrafa kaddarorin jiki kamar rashin ƙarfi, karko, ƙirƙira, tauri, da ƙarfi.Ƙarfe-ƙarfa masu zafi suna da mahimmanci ga masana'antu da yawa waɗanda suka haɗa da sararin samaniya, motoci, kwamfuta, da masana'antar kayan aiki masu nauyi.Zafi na maganin sassa na ƙarfe (kamar sukurori ko madaidaicin injin) yana haifar da ƙima ta haɓaka haɓakarsu da aiki.

Maganin zafi tsari ne mai matakai uku.Na farko, ana ƙona ƙarfe zuwa takamaiman zafin jiki da ake buƙata don kawo canjin da ake so.Na gaba, ana kiyaye zafin jiki har sai karfe ya yi zafi sosai.Ana cire tushen zafi, yana barin ƙarfe ya yi sanyi gaba ɗaya.

Karfe shine karfen da aka fi yi da zafi amma ana yin wannan tsari akan wasu kayan:

● Aluminum

● Tagulla

● Tagulla

● Zuba Ƙarfe

● Tagulla

● Hastelloy

● Inconel

● Nickel

● Filastik

● Bakin Karfe