Custom Sheet Metal

Sabis na Kera

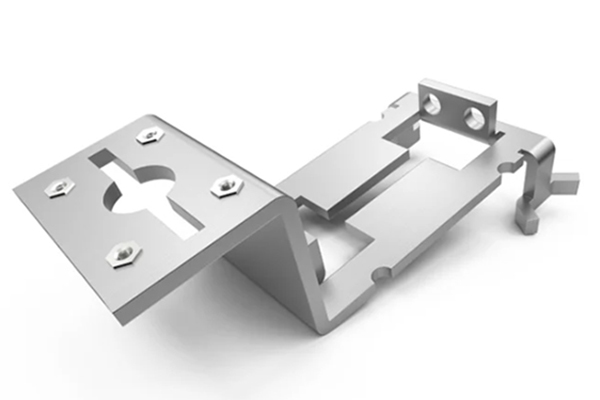

Aikin Karfe Sheet

The sheet karfe sarrafa fasahar ne hadaddun da bambancin, yafi ciki har da yankan, blanking, lankwasawa, da dai sauransu A lokaci guda, shi ma bayar da ayyuka kamar Laser yankan, spraying allo bugu, da taro bisa ga abokin ciniki ta zane zane bukatun.

Bari mu fara da kallon abin da ƙirƙira ƙirar takarda ta ƙunshi kafin mu ci gaba zuwa matakan mutum ɗaya waɗanda ke haifar da sassan ƙarfe da samfuran.

CNC Machined Metal Prototypes

Hanyar gargajiya don yin samfuran ƙarfe shine ta hanyar injin CNC.Za mu yi amfani da haɗin injin niƙa da lathe don ƙirƙirar samfurin ku.

Wannan zaɓin yana ɗaukar ɗan lokaci kaɗan fiye da bugu na 3D ko amfani da ƙarfe na takarda, amma an bar ku da wani sashi mai ƙarfi.Hakanan, injunan CNC na iya ɗaukar nau'ikan zaɓin kayan abu da kauri, don haka kuna da 'yanci da yawa idan ya zo ga ƙira.

Za mu iya amfani da matakan ƙarewa zuwa wani ɓangaren injin CNC, canza launi da halaye na farfajiya.

CNC machining na iya zama mafi tsada, dangane da takamaiman samfurin ku.Har yanzu babban zaɓi ne don gudanar da ƙarancin tsari, kuma zaku iya amfani da aikin injin ɗin CNC iri ɗaya don yin matsakaicin matsakaicin samarwa.

Kayan Injiniya Don Ƙirƙirar Ƙarfe na Ƙarfe

Ƙirƙirar samfurin samfur naku zai iya taimaka muku zaɓi madaidaicin kayan ƙarfe don samfurin ku, tweak girma, da haɓaka ayyuka.Ƙarshe, wannan yana sa samar da kayan aiki na ƙarshe ya fi tsada da lokaci mai kyau.

Ana amfani da nau'ikan karafa daban-daban don ƙirƙirar samfuran ƙarfe na takarda dangane da aikace-aikacen da matsayin.Masu sana'a suna amfani da nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan samfura don ƙirar samfuran ƙarfe.Wasu zaɓuɓɓukan ƙarfe waɗanda za a iya amfani da su don samfuran ƙarfe sune:

| Aluminum | jan karfe | Karfe |

| Aluminum 1050 | Copper 1020 | Bakin Karfe 301 |

| Aluminum 5052 | Copper 1100 | Bakin Karfe 303 |

| Aluminum 6061 | Copper 2100 | Bakin Karfe 304 |

| Aluminum 6063 | Copper 2200 | Bakin Karfe 430 |

| Aluminum 1100 | Copper 2300 | Bakin Karfe 316/316L |

| Copper 2400 | Karfe, Low Carbon | |

| Copper 260 (Brass) |

Yaya Sheet Metal Fabrication ke Aiki

Ya danganta da nau'in ɓangaren da za a kera, ƙayyadaddun ƙira da ƙarewar da ake so, ana iya samar da zanen ƙarfe a cikin matakai 3 masu sauƙi waɗanda suke yanke, kafawa, da haɗawa.(majalisa)

- Yanke

Za'a iya yin ayyukan yankan a cikin sarrafa ƙarfe ba tare da ƙarasa ba. - Hanyoyin yankan shear

Su ne blanking, yanke, da shearing.Hanyoyin da ba su da ƙarfi sun fi daidai kuma an keɓance su don ingantaccen samfuran ƙarshen masana'antu. - Hanyoyin da ba su da ƙarfi

Haɗa yankan katako na Laser, yankan jet na ruwa, yankan plasma, da machining.Sun fi dacewa da amfani da masana'antu a cikimotada Aerospace,robotics, wani lokacin kuma aikin injiniya. - Yanke Laser:

Yana amfani da hasken haske mai mai da hankali kan Laser don yanke ta cikin zanen ƙarfe.Hakanan za'a iya amfani dashi don sassaka karafa.

- Yanke jet na ruwa:

Babban tsari mai sauri wanda ke jagorantar rafukan ruwa masu tashe-tashen hankula a takardar don yanke cikin kayan. - Injiniya:

Zai iya zama na al'ada ko tushen CNC.Wannan tsari ya ƙunshi yin amfani da kayan aiki (dill bits ko lathe blades) don cire guntun kayan cikin tsari cikin tsari.CNC niƙa, kadi, da kuma juya su ne wasu shahararrun matakai. - Plasma:

Yankewar Plasma yana amfani da iskar gas mai ionized mai zafi wanda ke tafiya cikin sauri kuma yana gudanar da wutar lantarki don yanke kai tsaye a takardar ƙarfe. - Samar da:

Ƙirƙira ita ce laima ta gaba ɗaya don matakai kamar tambari, shimfiɗawa, naɗa, da lankwasawa.Ba kamar yanke inda aka cire kayan daga karfen takarda ba, ƙirƙira yana amfani da kayan aikin ƙirƙira kawai don sake fasalin ɓangaren zuwa lissafin da ake so. - Tambari:

Dabarar ƙira ta ƙunshi amfani da mutun biyu don danna ƙarfe zuwa siffar da ake so. - Lankwasawa:

Yana daidaita karfen takarda, kuma ana iya yin shi da hannu ko latsa birki, yayin da yin nadi yana amfani da juzu'i biyu don aiwatar da tsayin dakakken karfen a cikin nada. - Shiga:

Haɗuwa yawanci amma ba dole ba ne tsari na ƙarshe a cikin ƙirƙira ƙarfe na takarda.Ya ƙunshi matakai kamar riveting, adhesives, brazing, kuma mafi mashahuri, walda. - Walda:

Yana iya zama Stick, MIG, ko TIG.Tsarin da gaske yana haɗa zanen ƙarfe biyu ko sama da haka ta hanyar amfani da harshen wuta don narke su tare a gaban mai filler. - Riveting

Haɗa karafa tare ta hanyar haɗa ƙananan sassa na ƙarfe ta cikin zanen gado biyu. - Adhesives:

Manne-ƙarshen manne waɗanda ke da ikon riƙe karafa tare da kansu ko lokacin amfani da su tare da kowane tsarin haɗawa. - Brazing:

Brazing yana kama da walda, tare da kawai bambanci shine cewa ba a narkar da zanen karfe ba, sai dai filler.

Da zarar an ƙirƙira ɓangaren ƙarfe kuma an haɗa shi, ana iya amfani da ɗimbin ayyukan gamawa (dakikan da ke ƙasa) don haɓaka kaddarorinsa da bayyanarsa.

Nemi Magana

Shirya don Fara Aikin Haɓaka Ƙarfe na Musamman na Sheet tare da Kachi?

Danna nan don tuntuɓar mu kuma samun ƙimar kyauta yanzu!