I-Custom Sheet Metal

Izinkonzo Zokwenziwa

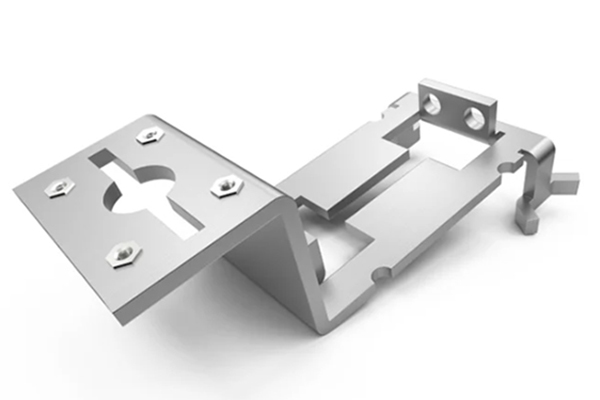

Ishidi Metal Processing

Ubuchwepheshe bokucubungula insimbi yeshidi buyinkimbinkimbi futhi buhlukahlukene, ikakhulukazi okuhlanganisa ukusika, ukuvala, ukugoba, njll. Ngesikhathi esifanayo, futhi inikeza izinsizakalo ezifana nokusika i-laser, ukuphrinta isikrini sokufafaza, nokuhlanganisa ngokuvumelana nezidingo zokuklama umdwebo wekhasimende.

Ake siqale ngokubheka ukuthi ukwakhiwa kwensimbi yeshidi kuhilelani ngaphambi kokudlulela esinyathelweni ngasinye esiholela ezingxenyeni zensimbi nemikhiqizo.

I-CNC Machined Metal Prototypes

Indlela yendabuko yokwenza ama-prototypes ensimbi ngokusebenzisa imishini ye-CNC.Sizosebenzisa inhlanganisela yomshini wokugaya kanye ne-lathe ukudala i-prototype yakho.

Le nketho ithatha isikhathi eside kunokuphrinta kwe-3D noma ukusebenzisa ishidi lensimbi, kodwa usele nengxenye eqinile.Futhi, imishini ye-CNC ingakwazi ukuphatha izinhlobonhlobo zezinketho zezinto ezibonakalayo nobukhulu, ngakho-ke unenkululeko eningi uma kuziwa ekuklameni.

Singafaka izinyathelo zokuqedela engxenyeni emshini we-CNC, sishintsha umbala nezici zangaphezulu.

Imishini ye-CNC ingase ibize kakhulu, kuye ngomkhiqizo wakho othize.Kuseyinketho enhle yokugijima kokukhiqizwa kwenqwaba ephansi, futhi ungasebenzisa umsebenzi ofanayo womshini we-CNC ukwenza ukukhiqizwa okuphakathi nendawo.

Izinto Zobunjiniyela Zokwenziwa Kwe-Sheet Metal Prototype

Ukudala i-prototype yomkhiqizo wakho kungakusiza ukuthi ukhethe insimbi efanele yomkhiqizo wakho, ulungise ubukhulu, futhi uthuthukise ukusebenza.Ekugcineni, lokhu kwenza ukukhiqizwa kokugcina kusebenze izindleko ezengeziwe nesikhathi.

Izinsimbi ezihlukahlukene zisetshenziselwa ukudala ama-prototypes ensimbi yeshidi kuye ngohlelo lokusebenza nezindima.Abakhiqizi basebenzisa izinsimbi zebanga elihlukile ukwenza imikhiqizo yensimbi ye-prototyping.Ezinye izinketho zensimbi ezingasetshenziswa kuma-prototypes ensimbi yilezi:

| I-Aluminium | ithusi | Insimbi |

| I-Aluminium 1050 | I-Copper 1020 | Insimbi Engagqwali 301 |

| I-Aluminium 5052 | I-Copper 1100 | Insimbi Engagqwali 303 |

| I-Aluminium 6061 | I-Copper 2100 | Insimbi Engagqwali 304 |

| I-Aluminium 6063 | I-Copper 2200 | Insimbi Engagqwali 430 |

| I-Aluminium 1100 | I-Copper 2300 | Insimbi Engagqwali 316/316L |

| I-Copper 2400 | Insimbi, Ikhabhoni Ephansi | |

| I-Copper 260(Ithusi) |

Isebenza kanjani i-Metal Fabrication

Kuye ngohlobo lwengxenye okufanele yenziwe, ubunkimbinkimbi bomklamo kanye nesiphetho esifunwayo, amashidi ensimbi angase akhiwe ngezinyathelo ezi-3 ezilula okungukuthi ukusika, ukwakha, nokuhlanganisa.(umhlangano)

- Ukusika

Imisebenzi yokusika ekucubunguleni insimbi yeshidi ingase yenziwe nge/ngaphandle kokugunda. - Izinqubo zokusika i-shear

Abanalutho, bayasikwa futhi bayagunda.Izinqubo ezingagundi zinembe kakhudlwana futhi zenzelwe imikhiqizo yokugcina yezimboni enembayo. - Izinqubo zokungagundi

Bandakanya ukusika kwe-laser beam, ukusika ijethi yamanzi, ukusika i-plasma, nokwenza imishini.Afaneleka kakhulu ukusetshenziswa ezimboniniezezimotokanye ne-aerospace,amarobhothi, futhi ngezinye izikhathi ubunjiniyela. - Ukusika i-Laser:

Isebenzisa i-laser-focused light beam ukusika amashidi ensimbi.Ingasetshenziselwa nokuqopha izinsimbi zeshidi.

- Ukusika indiza yamanzi:

Inqubo yesivinini esiphezulu eqondisa imifudlana yamanzi abrasive-concentrate eshidini ukuze isike ibe into. - Ukwenza imishini:

Kungaba ezejwayelekile noma CNC-based.Le nqubo ibandakanya ukusetshenziswa kwethuluzi (izingcezu zokubhoboza noma ama-lathe blades) ukuze kukhishwe ngohlelo izingcezu zento ethile engxenyeni.Ukugaya kwe-CNC, ukuphotha, nokuphenduka ngezinye zezinqubo ezidume kakhulu. - I-Plasma:

Ukusika kwe-Plasma kusebenzisa amagesi e-ionized acindezelwe ukushisa ahamba ngesivinini esikhulu futhi ahambise ugesi ukuze aqondise ukusikeka eshidini lensimbi. - Ukubumba:

Ukwakhiwa yisambulela esijwayelekile sezinqubo ezifana nokunyathela, ukwelula, ukwakha ama-roll, nokugoba.Ngokungafani nokusika lapho impahla isuswa khona eshidini lensimbi, ukwakha kumane kusebenzisa amathuluzi okwakha ukuze kumise ingxenye kujometri oyifunayo. - Ukugxiviza:

Indlela yokwenza ihlanganisa ukusetshenziswa kwama-dies amabili ukuze ucindezele insimbi ibe yisimo oyifunayo. - Ukugoba:

Ijikisa insimbi yeshidi, futhi ingenziwa ngesandla noma ngokucindezela amabhuleki, kuyilapho ukwenza ama-roll kusebenzisa ipheya yamaroli ukuze kucutshungulwe ubude beshidi lensimbi libe ikhoyili. - Ukujoyina:

Ukujoyina ngokuvamile kodwa akuyona inqubo yokugcina ekwenziweni kweshidi lensimbi.Kubandakanya izinqubo ezifana nokufaka ama-riveting, ama-adhesives, brazing, futhi okudume kakhulu, ukushisela. - Ukushisela:

Kungaba yiStick, MIG, noma TIG.Inqubo ihlanganisa amashidi ensimbi amabili noma ngaphezulu ngokusebenzisa ilangabi ukuze liwancibilikise ndawonye phambi kwesigcwalisi. - I-Riveting

Ihlanganisa izinsimbi zeshidi ndawonye ngokushumeka izingxenye zensimbi ezincane kuwo womabili amashidi. - Izinamathiselo:

Amaglue asezingeni eliphezulu akwazi ukubamba izinsimbi zeshidi ndawonye ngokwawo noma uma esetshenziswa ngokuhambisana nanoma iyiphi enye inqubo yokuhlanganisa. - I-Brazing:

I-Brazing ifana ne-welding, umehluko kuphela ukuthi amashidi ensimbi awancibiliki, kuphela i-filler.

Uma ingxenye yensimbi seyenziwe futhi yahlanganiswa, inqwaba yezinqubo zokuqeda (eningiliziwe ngezansi) ingasetshenziswa ukuthuthukisa izakhiwo zayo nokubukeka kwayo.

Cela I-Quote

Usulungele Ukuqala Iphrojekthi Yakho Yangokwezifiso Yokwenziwa Kwensimbi Nge-Kachi?

Chofoza lapha ukuze uxhumane nathi futhi uthole lesisho samahhala manje!