Isevisi yemishini ye-CNC

Izixazululo zokukhiqiza ezenziwe ngokwezifiso zezingxenye zomshini we-CNC.

Ukuhlinzeka ngama-prototypes aphuma kanye kanye nokukhiqizwa kwenani eligcwele.

Thintana nathi namuhla ukuze ucele ikhotheshini yezinsizakalo zethu zemishini ye-CNC.

Iyini i-CNC Machining?

I-CNC Machining iyinqubo elawulwa ngekhompuyutha ebandakanya ukukhishwa kwempahla kucezu lokusebenza.

Le ndlela iphumelela kakhulu, inembile, futhi iyashesha uma iqhathaniswa namasu okugaya endabuko.

Iyini Imishini Ye-CNC Isetshenziselwa?

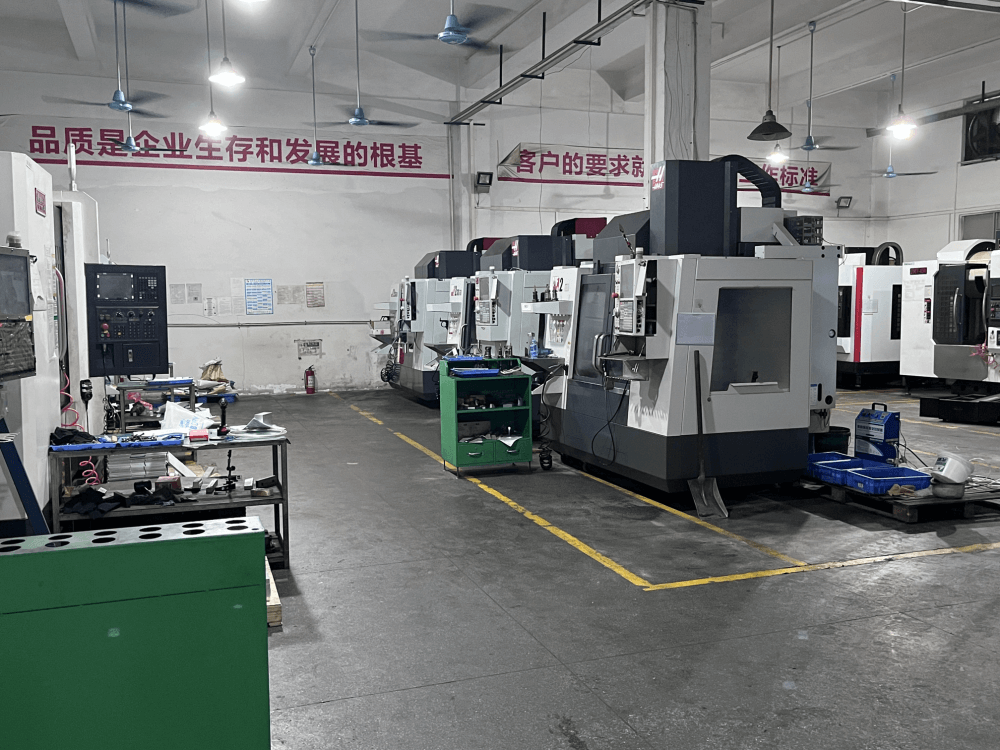

E-Kachi, sinikezela ngezinsizakalo zokunemba ze-CNC zokukhiqiza izingxenye eziqediwe eziyinkimbinkimbi, izakhi, namathuluzi wokubumba umjovo wepulasitiki noma ukufakwa kwe-pressure die cast.Ukwengeza, ukukhiqizwa kwe-CNC kusetshenziselwa ukubhola kwesibili, ukuthepha, kanye nokusebenza kokugaya ezingxenyeni zomshini noma izingxenye ezenziwe ngezinye izinqubo.Ithimba lethu lisebenzisa izinhlobonhlobo zamathuluzi omshini we-CNC akhethekile ukwenza imisebenzi ehlukahlukene esitokweni esingavuthiwe, kodwa izigayo ze-CNC ziyimishini esetshenziswa kakhulu futhi eguquguqukayo yama-axis amaningi ekusebenzeni kwethu kwansuku zonke.

Isevisi yethu ye-CNC

I-Kachi ihlinzeka ngezinsizakalo zokugaya kanye ne-lathe yangokwezifiso ye-CNC.

Funda kabanzi mayelana nokuthi yimaphi amasevisi esiwanikezayo.

CNC Turnign Services

Inqubo evamile yokuphenduka ihilela ukuzungezisa ingxenye kuyilapho ithuluzi lokusika elinephoyinti elilodwa lihanjiswa ngokuhambisana ne-eksisi yokuzungezisa.Ukuphenduka kungenziwa endaweni yangaphandle yengxenye kanye nangaphakathi (inqubo eyaziwa ngokuthi i-boring).Izinto zokuqala ngokuvamile ziwucezu lokusebenza olukhiqizwa ezinye izinqubo ezifana nokulingisa, ukufoja, ukukhipha, noma ukudweba.

CNC Milling Services

Ukugaya kuyinqubo yomshini usebenzisa ama-rotary cutters ukuze asuse izinto ngokuthuthukisa i-cutter ibe ucezu lokusebenza.Lokhu kungenziwa ngokuhlukahluka kwezikhombisi-ndlela ku-ax eyodwa noma eziningana, isivinini sekhanda lokusika, nokucindezela.Ukugaywa kuhlanganisa imisebenzi nemishini eyahlukene, esikalini kusukela ezingxenyeni ezihlukene ngazinye kuya emisebenzini emikhulu yokugaya yamaqembu ezigelekeqe.Kungenye yezinqubo ezisetshenziswa kakhulu ukwenza izingxenye zangokwezifiso ukuze zibekezelelane ngokuqondile.

Imihlahlandlela nemisebenzi yokugaya i-CNC

Izimiso zethu ezibalulekile zihlanganisa izici ezibalulekile zedizayini ezihloselwe ukuthuthukisa ukwenziwa, ukuthuthukisa ukubukeka, kanye nokunciphisa sonke isikhathi sokukhiqiza.

Ukuphenduka Kwesigaba Sesisetshenziswa Sekhono

Inqubo yethu yokuguqula i-CNC isebenza kahle kakhulu futhi isivumela ukuthi sikhiqize ama-prototypes angokwezifiso kanye nezingxenye zokugcina esikhathini esincane nje sosuku olulodwa.Sisebenzisa amalebula e-CNC esimanje ahlonyiswe ngamathuluzi kagesi ukuze sishise izinhlobonhlobo zezici ezifana nezimbobo ze-axial kanye ne-radial, amaflethi, ama-grooves, nezikhala.

Ukushuna kwe-CNC kuvame ukusetshenziswa ezimeni ezahlukahlukene, kufaka phakathi:

- Ukukhiqiza izingxenye zama-prototypes asebenzayo nemikhiqizo yokugcina

- Ukudala izingxenye ezinezici ze-cylindrical

- Ukukhiqiza izingxenye ezinezimbobo ze-axial kanye ne-radial, amafulethi, ama-grooves, kanye nezikhala

Ithimba lethu lonjiniyela abanolwazi kanye nochwepheshe bemishini basebenzisana eduze namakhasimende ukuqinisekisa ukuthi izingxenye zabo zenziwe ngomshini ngendlela ezicaciswa ngayo.Sisebenzisa isofthiwe yakamuva namathuluzi ukuhlela imishini yethu, siqinisekisa ukuthi zonke izingxenye zenziwa ngokunemba nangokunemba.

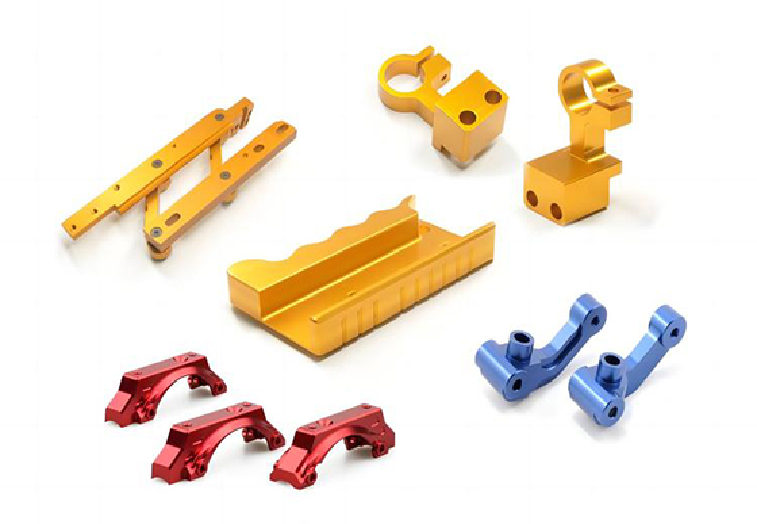

Uma inqubo yokwenza imishini isiqediwe, izingxenye zethu zihlolwa ngokuqinile ikhwalithi ukuze kuqinisekiswe ukuthi zihlangabezana nezindinganiso zethu eziphakeme zekhwalithi nokungaguquguquki.Siphinde sinikeze ngezinketho zokuqeda, okuhlanganisa i-anodizing kanye ne-chrome plating, ukunikeza izingxenye zethu ukubukeka okuphrofeshinali nokupholishiwe.

Esikhungweni sethu, sizimisele ukuhlinzeka amakhasimende ethu ngezingxenye namasevisi asezingeni eliphezulu kakhulu.Kungakhathaliseki ukuthi udinga i-prototype eyodwa noma ukukhiqizwa okukhulu, sinolwazi namakhono okuhlangabezana nezidingo zakho.

Izinkombandlela Zokuklama Zokuguqula i-CNC

Imihlahlandlela yethu ithuthukisa ukwenziwa kwengxenye futhi yehlise nesikhathi sokukhiqiza.

| Ubukhulu bobukhulu | Ububanzi | 100.33mm |

| Ubude | 228.6mm | |

| Ubuncane bobukhulu | Ububanzi | 4.07mm |

| Ubude | 1.27mm | |

| Ukuqina Kwezindonga | 0.51mm | |

| I-engeli | 30° | |

| Ukubekezelelana | +/- 0.13mm |

Ukuqedela okungaphezulu kuhilela inqubo yokuguqula indawo yensimbi ngokubunjwa kabusha, ukususa noma ukwengeza, futhi kusetshenziselwa ukukala ukuthungwa okuphelele kwendawo ebonakala ngokuthi:

I-Lay - Isiqondiso sephethini yendawo ephezulu (evame ukunqunywa inqubo yokukhiqiza).I-Waviness - Iphathelene nokungapheleli kwemininingwane emihle noma ukungalungi kahle, okufana nezindawo ezisontekile noma eziphambukile ekucacisweni.

I-Lay - Isiqondiso sephethini yendawo ephezulu (evame ukunqunywa inqubo yokukhiqiza).I-Waviness - Iphathelene nokungapheleli kwemininingwane emihle noma ukungalungi kahle, okufana nezindawo ezisontekile noma eziphambukile ekucacisweni.

Izinzuzo ze-Metal Surface Finishing Process

Imisebenzi yokwelashwa kwendawo yensimbi ingafingqwa ngale ndlela elandelayo:

-Thuthukisa ukubukeka kwezingxenye

-Engeza imibala ethile emihle

- Shintsha ukukhanya

-Thuthukisa ukumelana namakhemikhali

-Khulisa ukumelana nokugqoka

-Nciphisa imiphumela yokugqwala

-Yehlisa ukungqubuzana

-Susa amaphutha angaphezulu

- Ukuhlanza izingxenye

-Isebenza njengejazi lokuqala

-Lungisa osayizi

I-Kachi CNC Machining Service FAQ

Singabahlinzeki besevisi bemishini be-CNC abakhulu ngokwesipiliyoni, ubuchwepheshe kanye nedumela.

Imishini ye-CNC ingasebenza ngezinto eziningi ezihlukahlukene, okuhlanganisa izinsimbi (njenge-aluminium, ithusi, nensimbi), amapulasitiki (njenge-ABS, inayiloni, ne-polycarbonate), kanye nokhuni.

Isikhathi esisithathayo ukukhiqiza izingxenye ezinomshini we-CNC sincike ezintweni ezimbalwa, okuhlanganisa ubunkimbinkimbi bengxenye, uhlobo lwento esetshenzisiwe, kanye nosayizi we-oda.Ngokuvamile, nokho, ukwenza imishini ye-CNC kuyinqubo eshesha kakhulu.

Izindleko zomshini we-CNC ziyahlukahluka kuye ngezinto ezimbalwa, okuhlanganisa ubunzima bengxenye, uhlobo lwento esetshenzisiwe, kanye nosayizi we-oda.Ngokuvamile, nokho, ukwenza imishini ye-CNC kuyindlela engabizi kakhulu yokukhiqiza izingxenye nemikhiqizo yekhwalithi ephezulu.

Imishini yethu ye-CNC ikwazi ukuzuza ukubekezelelwa okujwayelekile kwama-microns angu-0.05 ezinhlelweni eziningi zezohwebo nezimboni.Uma udinga ukubekezelelana okuqinile kumaphrojekthi akhethekile, sicela ukhululeke ukuxhumana nathi ukuze uthole izinsizakalo zokubonisana ezichwepheshile.

Izizathu Zokukhetha Izinkonzo Zethu

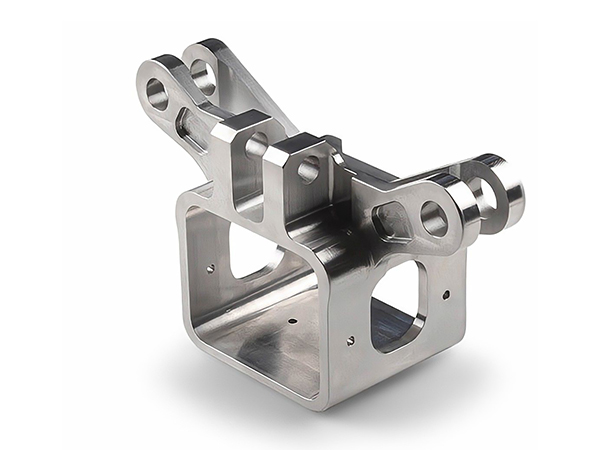

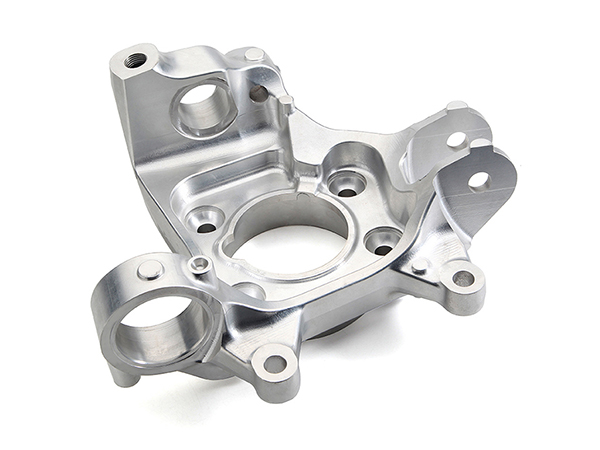

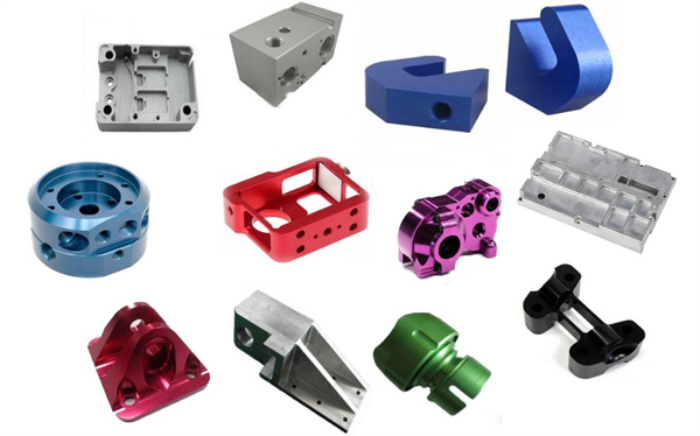

I-Precision CNC Machined Parts Showcase

Hlola igalari yethu ebanzi yama-prototypes ekhwalithi ephezulu nezingxenye ezibonisa imikhiqizo yangokwezifiso eyenziwe amakhasimende ami ahloniphekile