Tšebeletso ea Machining ea CNC

Litharollo tse entsoeng ka mokhoa o ikhethileng bakeng sa likarolo tse entsoeng ka mochini oa CNC.

Ho fana ka li-prototypes tsa nako e le 'ngoe hammoho le tlhahiso ea boima bo feletseng.

Ikopanye le rona kajeno ho kopa quote bakeng sa lits'ebeletso tsa rona tsa mochini oa CNC.

CNC Machining ke Eng?

CNC Machining ke ts'ebetso e laoloang ke komporo e kenyelletsang ho tlosoa ha thepa ho tsoa ho workpiece.

Mokhoa ona o sebetsa hantle haholo, o nepahetse ebile o potlakile ha o bapisoa le mekhoa ea khale ea machining.

CNC Machining e sebelisetsoa eng?

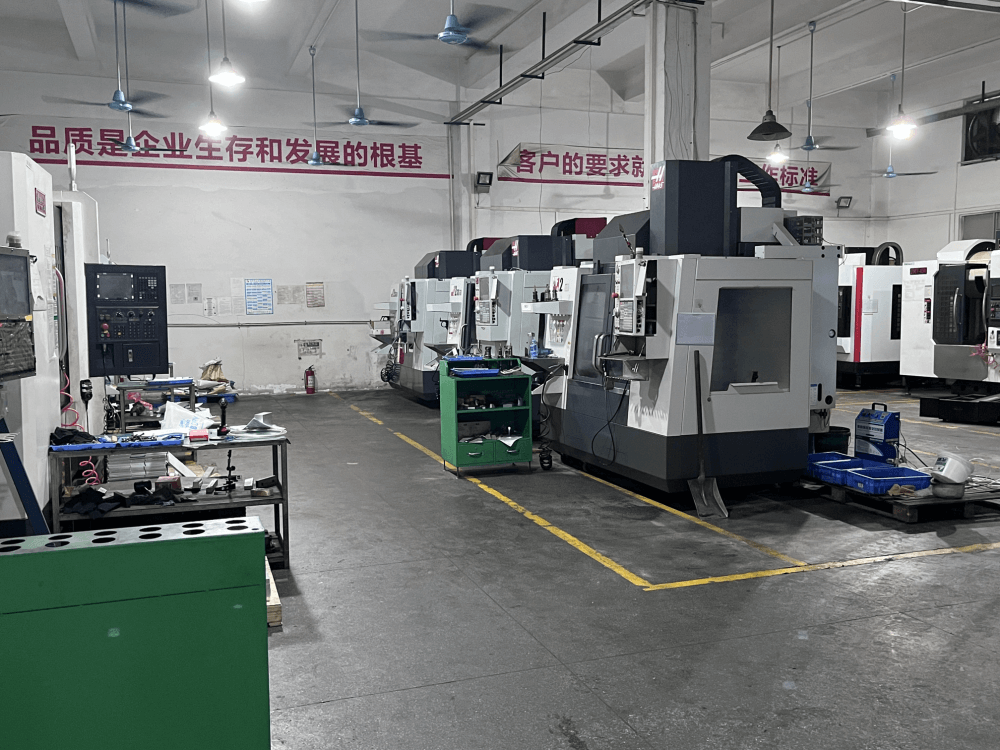

Ho Kachi, re fana ka lits'ebeletso tsa machining tsa CNC tse nepahetseng bakeng sa tlhahiso ea likarolo tse thata tse felileng, likarolo le lisebelisoa tsa ho etsa ente ea polasetiki kapa ho lahla khatello.Ntle le moo, tlhahiso ea CNC e sebelisoa bakeng sa ts'ebetso ea bobeli ea ho cheka, ho tlanya le ho sila likarolong tse entsoeng ka mochini kapa likarolo tse entsoeng ka lits'ebetso tse ling.Sehlopha sa rona se sebelisa mefuta e fapaneng ea lisebelisoa tse khethehileng tsa mochini oa CNC ho etsa ts'ebetso e fapaneng ea lihlahisoa tse tala, empa li-mill tsa CNC ke mechini e sebelisoang haholo le e fapaneng ea li-axis tse ngata ts'ebetsong ea rona ea letsatsi le letsatsi.

Tšebeletso ea rona ea CNC

Kachi e fana ka litšebeletso tsa CNC tsa ho sila le tsa lathe.

Ithute haholoanyane ka litšebeletso tseo re fanang ka tsona.

Litšebeletso tsa ho fetola CNC

Mokhoa o akaretsang oa ho reteleha o kenyelletsa ho potoloha karolo ha sesebelisoa sa ho seha se nang le ntlha e le 'ngoe se tsamaisoa ho bapa le axis ea ho potoloha.Ho reteleha ho ka etsoa karolong e ka ntle ea karolo hammoho le bokaholimo ba ka hare (mokhoa o tsejoang e le boring).Thepa ea ho qala hangata ke sesebelisoa se hlahisoang ke lits'ebetso tse ling tse kang ho lahla, ho forging, extrusion, kapa ho taka.

Litšebeletso tsa Milling tsa CNC

Ho sila ke mokhoa oa ho sebetsa ho sebelisa li-cutters tsa rotary ho tlosa thepa ka ho ntšetsa pele sehaho hore e be sesebedisoa.Sena se ka etsoa ka litsela tse sa tšoaneng holim'a selepe se le seng kapa tse 'maloa, lebelo la ho khaola hlooho le khatello.Ho sila ho akaretsa mefuta e mengata e fapaneng ea ts'ebetso le metjhini e fapaneng, ka sekala ho tloha ho likarolo tse nyane ho isa ho ts'ebetso e kholo, e boima e boima ea litlokotsebe.Ke e 'ngoe ea mekhoa e sebelisoang haholo bakeng sa ho lokisa likarolo tsa moetlo ho mamellana hantle.

Tataiso le mesebetsi bakeng sa ho sila CNC

Melao-motheo ea rona e kenyelletsa lintlha tsa bohlokoa tsa moralo tse reretsoeng ho ntlafatsa tlhahiso, ho ntlafatsa ponahalo, le ho fokotsa nako ea tlhahiso ka kakaretso.

Thepa ea Bokhoni Karolo e Fetola

Ts'ebetso ea rona ea ho fetola CNC e sebetsa hantle haholo ebile e re lumella ho hlahisa li-prototypes le likarolo tsa ho qetela ka nako e nyane joalo ka letsatsi le le leng.Re sebelisa lisebelisoa tsa morao-rao tsa CNC tse nang le lisebelisoa tsa motlakase ho kenya lisebelisoa tse ngata tse kang likoti tsa axial le radial, flats, grooves, le slots.

CNC tuning hangata e sebelisoa maemong a fapaneng, ho kenyelletsa:

- Ho etsa likarolo tsa li-prototype tse sebetsang le lihlahisoa tsa ho qetela

- Ho theha likarolo tse nang le likarolo tsa cylindrical

- Ho hlahisa likarolo tse nang le masoba a axial le radial, flats, grooves le slots

Sehlopha sa rona sa baenjiniere ba nang le boiphihlelo le bo-machinist ba sebetsa haufi-ufi le bareki ho etsa bonnete ba hore likarolo tsa bona li entsoe ho latela litlhaloso tsa bona.Re sebelisa software le lisebelisoa tsa morao-rao ho hlophisa mechini ea rona, ho netefatsa hore karolo e 'ngoe le e 'ngoe e etsoa ka nepo le ka nepo.

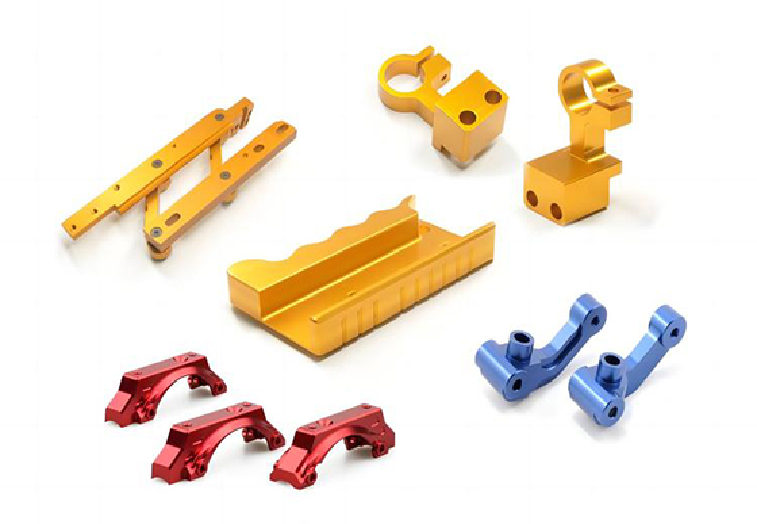

Hang ha ts'ebetso ea mochini e phethiloe, likarolo tsa rona li hlahlojoa ka matla ho netefatsa hore li fihlella litekanyetso tsa rona tse phahameng tsa boleng le botsitso.Re boetse re fana ka mefuta e mengata ea likhetho tsa ho qeta, ho kenyelletsa anodizing le chrome plating, ho fa likarolo tsa rona ponahalo ea setsebi le e bentšitsoeng.

Setsing sa rona, re ikemiselitse ho fa bareki ba rona likarolo le litšebeletso tsa boleng bo holimo.Hore na o hloka prototype e le 'ngoe kapa tlhahiso e kholo ea tlhahiso, re na le boiphihlelo le bokhoni ba ho fihlela litlhoko tsa hau.

Litaelo tsa Moralo bakeng sa Phetoho ea CNC

Litaelo tsa rona li ntlafatsa karolo ea tlhahiso le ho fokotsa nako ea tlhahiso.

| Maximum Dimensions | Diameter | 100.33 limilimithara |

| Bolelele | 228.6 limilimithara | |

| Minimum Dimensions | Diameter | 4.07 limilimithara |

| Bolelele | 1.27 limilimithara | |

| Botenya ba Lerako | 0.51 limilimithara | |

| Lenaka | 30° | |

| Mamello | +/- 0.13mm |

Ho qeta bokaholimo ho kenyelletsa mokhoa oa ho fetola bokaholimo ba tšepe ka ho bopa bocha, ho tlosa kapa ho eketsa, 'me ho sebelisoa ho lekanya sebopeho se akaretsang sa bokaholimo bo khetholloang ke:

Lay - Tataiso ea mokhoa o ka sehloohong oa holim'a metsi (hangata o khethoa ke mokhoa oa tlhahiso).Waviness - E amana le ho se phethahale kapa lintlha tse sa tsitsang, joalo ka libaka tse sothehileng kapa tse khelohileng ho latela litlhaloso.

Lay - Tataiso ea mokhoa o ka sehloohong oa holim'a metsi (hangata o khethoa ke mokhoa oa tlhahiso).Waviness - E amana le ho se phethahale kapa lintlha tse sa tsitsang, joalo ka libaka tse sothehileng kapa tse khelohileng ho latela litlhaloso.

Melemo ea Metal Surface Finishing Process

Mesebetsi ea phekolo ea holim'a tšepe e ka akaretsoa ka tsela e latelang:

- Ntlafatsa ponahalo ea likarolo

-Eketsa mebala e metle e ikhethang

- Fetola khanya

- Ntlafatsa khanyetso ea lik'hemik'hale

-Eketsa khanyetso ea ho apara

- Fokotsa litlamorao tsa kutu

- Fokotsa khohlano

-Tlosa bofokoli ba bokaholimo

-Ho hloekisa likarolo

- E sebetsa joalo ka seaparo sa pele

- Fetola boholo

Kachi CNC Machining Service FAQ

Re bafani ba litšebeletso tse ntle tsa machining tsa CNC mabapi le boiphihlelo, boiphihlelo le botumo.

Mechini ea CNC e ka sebetsa ka mefuta e mengata ea lisebelisoa, ho kenyelletsa le litšepe (tse kang aluminium, koporo le tšepe), lipolasetiki (tse kang ABS, nylon le polycarbonate) le lehong.

Nako eo e e nkang ho hlahisa likarolo ka mochini oa CNC e ipapisitse le lintlha tse 'maloa, ho kenyelletsa le ho rarahana ha karolo, mofuta oa thepa e sebelisoang, le boholo ba tatellano.Leha ho le joalo, ka kakaretso, CNC machining ke ts'ebetso e batlang e potlakile.

Litsenyehelo tsa mochini oa CNC li fapana ho latela lintlha tse 'maloa, ho kenyelletsa le ho rarahana ha karolo, mofuta oa thepa e sebelisoang, le boholo ba tatellano.Leha ho le joalo, ka kakaretso, CNC machining ke mokhoa o theko e boima oa ho hlahisa likarolo le lihlahisoa tsa boleng bo holimo.

Mechine ea rona ea CNC e khona ho fihlela mamello e tloaelehileng ea li-micron tse 0.05 bakeng sa lits'ebetso tse ngata tsa khoebo le tsa indasteri.Haeba o hloka mamello e matla bakeng sa merero e khethehileng, ka kopo ikutloe u lokolohile ho ikopanya le rona bakeng sa lits'ebeletso tsa boeletsi ba litsebi.

Mabaka a ho Khetha Litšebeletso tsa Rōna

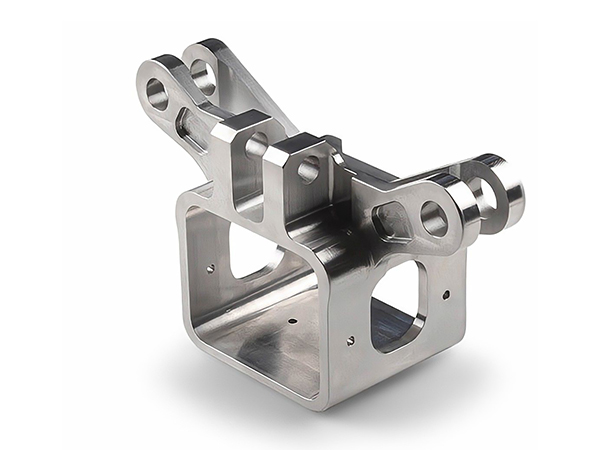

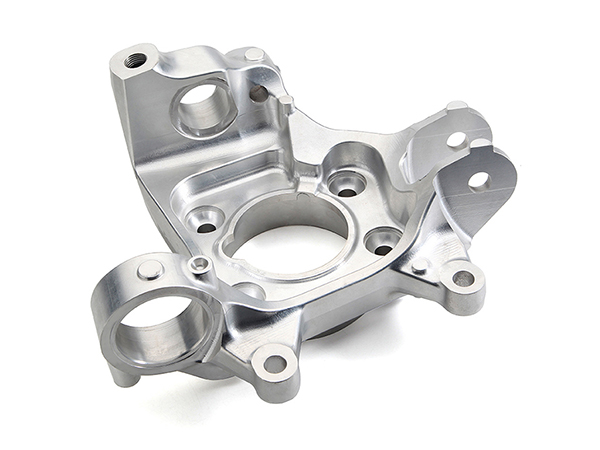

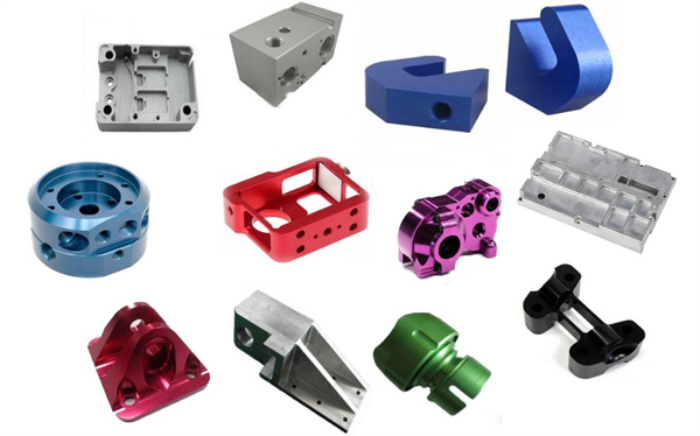

Precision CNC Machined Parts Showcase

Lekola setsi sa rona se pharalletseng sa li-prototypes tsa boleng bo holimo le likarolo tse bonts'ang lihlahisoa tse ikhethileng tse entsoeng ke bareki ba ka ba hlomphuoang.