I-CNC machining inezinzuzo eziningi, ngakho-ke abakhiqizi bayayikhetha.Yize ukwenziwa kwemishini ye-CNC kusebenza kahle kakhulu futhi kungenaphutha kunomshini ojwayelekile, ukuhlolwa kwekhwalithi kusabalulekile.Ukulawulwa kwekhwalithi nokuhlolwa kwenziwa kuzo zonke izigaba zokucubungula.Ngaphezu kwalokho, ukuqinisekiswa kwekhwalithi nakho kubalulekile, okuwuhlelo lokuhlola ikhwalithi olubekwe izinhlangano nama-ejensi agunyaziwe, okuhlanganisa imibhalo ehlobene.Ukulawulwa kwekhwalithi kubalulekile kuzo zonke izimboni, kungakhathaliseki ukuthi imikhiqizo, izingxenye, izinqubo, amathuluzi, noma imishini.Ukuze kuhlangatshezwane nokulindelwe yikhasimende, izindinganiso zokuhweba, nemithetho yemboni, i-Kachi isebenzisa amathuluzi okulinganisa ahlukahlukene namathuluzi ukulawula ikhwalithi yezingxenye zomshini ze-CNC ezikhiqizwa esitolo sethu semishini.

Lesi sihloko sixoxa ngokubaluleka kwamaphuzu angu-6ukuhlolwa kwekhwalithikanye nezindlela zemishini ye-CNC nezindlela zokulawula ikhwalithi.

Izinkampani zemishini ye-CNC zidlala indima ebalulekile ekwenziweni kwezinkontileka kanye nezinsizakalo zokukopisha ngokushesha.Impumelelo yale misebenzi incike ekugcineni ukubekezelelana okunembe ngokwedlulele, ngokuvamile ezingeni elincane kakhulu.Ukuze ufanekise lokhu, cabangela i-valve yolayini kaphethiloli usayizi wayo kufanele ube phakathi kuka-1 mm wosayizi oshiwo.Noma yikuphi ukuchezuka kule mfuneko kungase kubangele ukuvuza kukawoyela ezinkulungwaneni zezimoto.Imiphumela efanayo engahlosiwe ingase yenzeke ezimbonini ezifana ne-aerospace, ukwakha umkhumbi, nokukhiqiza izinto zikagesi.Ngakho-ke, kubalulekile ukwenza izinyathelo zokulawula ikhwalithi ezisebenzayo.

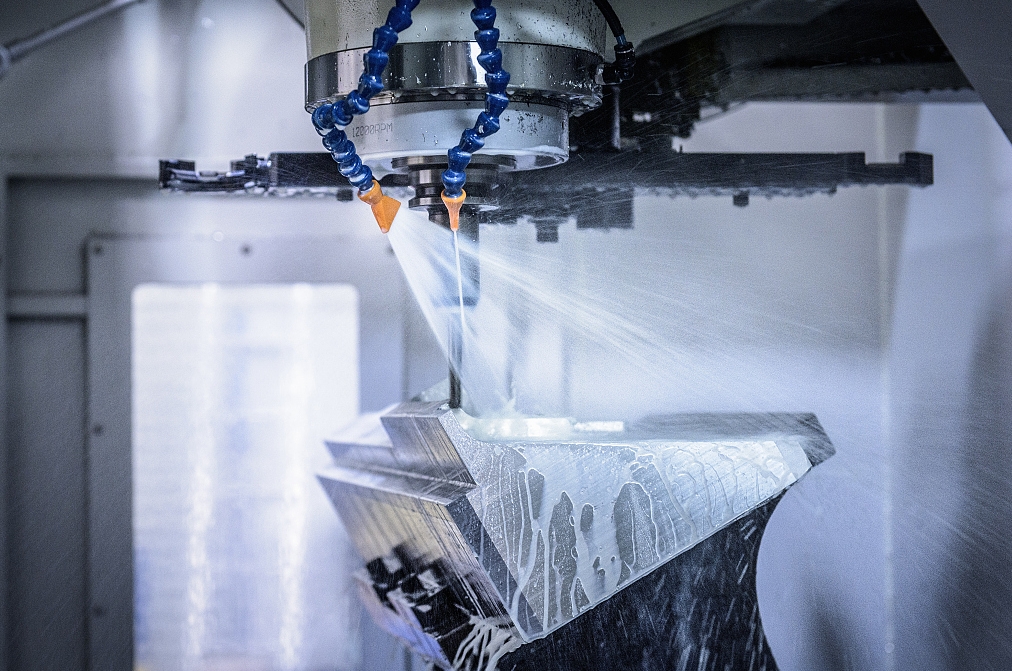

Ukuqinisekisa ukuthi okokusebenza kuyakwazi ukukhiqiza umkhiqizo owufunayo noma i-prototype kuyisinyathelo sokuqala sokulawula ikhwalithi.Imishini ye-CNC ihlanganisa imishini eyahlukene, okuhlanganisa imishini yokugaya, imishini yokugaya, nemishini yokugaya.Lapho uthenga imishini, kunconywa ukuthi ukhethe umthengisi ohloniphekile.Uma ukhetha ukuthenga izinto ezisetshenziswayo ngokuzithenga noma ngokuziqashisa, kufanele ufake isicelo sewaranti.

Ukulinganisa okuvamisile nokuthobela izimiso zokulungisa kuphakathi kwezinqubo ezibucayi kakhulu zokugcina amazinga ekhwalithi ephezulu.Imishini ingalahlekelwa ukulinganiswa ngenxa yokudlidliza, ukushaqeka, nezinye izehlakalo ekubukeni phansi kwemboni.Ngeshwa, kunamaphrothokholi amaningi okulungisa ama-spindles kumishini ye-CNC.Kodwa-ke, ukuzifaka ohlelweni olubanzi lokulungisa kungaletha izinzuzo ezibalulekile ngokunciphisa isikhathi sokuphumula.

Indima yokuhlola mathupha kancane kancane ithathelwa indawo noma yengezelelwe intuthuko yezobuchwepheshe.Abakhiqizi bangasebenzisa izisebenzi zabo zokulawula ikhwalithi (i-QC) ukuze bahlole noma bameme abahloli ezimbonini zabo ukuze bahlolwe.Ukugcina amarekhodi elinye isu elisebenzayo lezitolo ze-CNC ukuthuthukisa ikhwalithi.Ngokurekhoda imiphumela yokuhlolwa nokuyethula ngamagrafu noma amatafula, abasebenzi be-QC bangakwazi ukufinyelela kalula idatha kuyo yonke imishini ye-CNC esesitezi sefekthri.Lokhu kubavumela ukuthi baqaphe izindaba ezijwayelekile nezingajwayelekile.

Ikhwalithi yomshini we-CNC ekugcineni incike kulwazi lomsebenzisi.Nokho, okwamanje kunezikhala zamakhono kubasebenzi, okuhlanganisa nokushoda kwabasebenzi be-CNC.Isixazululo esisodwa saleli gebe ukuthi abakhiqizi bakhe ubudlelwano nezikhungo zemfundo ephakeme zasendaweni futhi banikeze amathuba okufundela umsebenzi kulabo abasafufusa ukuba basebenze ku-CNC.

Isitifiketi se-ISO, esifana ne-ISO 9000, siyimpahla ebalulekile yezinkampani zokwenza imishini ye-CNC.Ukuthola nokugcina isitifiketi se-ISO kungathuthukisa izinqubo zebhizinisi, kunciphise izinsalela nokusebenza kabusha, futhi kunciphise izindleko.Ukwengeza, isitifiketi se-ISO siyithuluzi elinamandla labasebenzi bokuthengisa nabamaketha.Abanye abakhiqizi abanezitifiketi ze-ISO baze bafune ukuthi nabahlinzeki babo nabo bagunyazwe.

Kungani kubalulekile ukulawula izinga?

Ukulawulwa kwekhwalithi wukuhlola okuphelele komkhiqizo kanye nenqubo yokukhiqiza.Emashini e-CNC, ukulawulwa kwekhwalithi kubalulekile ukuze kuqinisekiswe ukuthi imikhiqizo ekhiqiziwe ihlangabezana namazinga nezidingo zebhizinisi, izimboni kanye nekhasimende.Ngaphezu kwalokho, ukulawulwa kwekhwalithi okufanele kwezingxenye ze-CNC kuzogwema imikhiqizo enesici, kunciphise ubungozi, kuqinisekise ukunemba kobukhulu kanye nekhwalithi, konga izinsiza, kunciphise izindleko, futhi kuthuthukise ukusebenza kahle.Lokhu kuyinto enhle kubo bobabili abakhiqizi namakhasimende.

Wenza kanjani ukulawula izinga?

Ukuxhumana kwamakhasimende

Ukuxhumana kwamakhasimende okuphumelelayo kuyisici esibalulekile ekuzuzeni ukwaneliseka kwamakhasimende.Kungakhathaliseki ukuthi ngesikhathi senqubo yokukhiqiza noma ngemva kokuthumela amasampula, ukuxhumana okufika ngesikhathi namakhasimende kusebenza kahle.Abathengi namakhasimende banezidingo ezicacile zokucaciswa komkhiqizo nemisebenzi.Uma sithola uphenyo lwekhasimende, sizoxhumana nekhasimende ngokushesha futhi sinikeze ikhotheshini yamahhala ngokushesha okukhulu.Uma kunenkinga, sizolungisa isisombululo ngokushesha.Sicela usazise kusengaphambili uma unezidingo ezikhethekile.

Qonda ukwakheka komkhiqizo

Lapho amakhasimende ethumela imidwebo ye-CAD yemikhiqizo yokugcina, onjiniyela badinga ukuhlaziya umklamo ngokuningiliziwe, baqonde ukucaciswa komkhiqizo wekhasimende kanye nezimfuneko, futhi bahlole yonke imininingwane ngaphambi kokukhiqiza.Sizosebenzisa isixazululo esingabizi kakhulu ukwenza ingxenye yakho ngomshini, silawule izici kuyo yonke inqubo yemishini ye-CNC, futhi siqinisekise ukuthi izidingo ziyahlangatshezwa.

Imikhiqizo Nesevisi

Izinqubo zokuqapha nokulinganisa zayo yonke imikhiqizo eyenziwe ngomshini ngokunemba zichazwa emidwebeni nasekucacisweni, imizila yokukhiqiza, amadokhumenti okuthenga, kanye nezinqubo zokuhlola nokuhlola.

Ukuqinisekiswa komkhiqizo othengiwe

Yonke imikhiqizo ethengiwe ihlolwa ngokubonwa ngumhloli owamukelayo.Imikhiqizo ekhethiwe futhi ingaphansi kokuhlolwa okuningiliziwe kokulawulwa kwekhwalithi yobuchwepheshe (QC).

Ukuhlolwa kwenqubo

Ukuhlolwa kwenqubo kuthatha uhlobo lokuhlolwa kwe-athikili yokuqala nokuhlolwa komsebenzisi ukuze kuqinisekiswe ikhwalithi kanye nokulethwa ngesikhathi kwama-oda aqediwe kumakhasimende ethu.

Ukuhlolwa kokugcina

Imikhiqizo eqediwe ye-CNC ihlolwa okokugcina kwe-QC.Okokuqala, umhloli uyaqinisekisa ukuthi konke ukuhlolwa okucacisiwe kanye nokuhlolwa okusetshenzwayo sekuqediwe.Bese benza ukuhlola nokuhlola okusele ukuze baqedele isitifiketi somkhiqizo sokuthobela imithetho.Imiphumela yakho konke ukuhlolwa nokuhlolwa izorekhodwa, futhi yimikhiqizo kuphela ephumelela inqubo yokugcina yokuhlola ezopakishwa futhi ithunyelwe.

Ama-opharetha azophatha izingxenye zokugcina ezenziwe ngomshini.Kunamathuluzi ahlukahlukene okulinganisa athuthukile atholakalayo ezilinganisweni eziningi zokuhlola njengosayizi, ubulukhuni, umbala, ukubekezelelana, njll.

Isikhathi sokuthumela: Nov-07-2023