I-CNC machining ineenzuzo ezininzi, ngoko ke abavelisi bayayikhetha.Nangona ukwenziwa komatshini we-CNC kusebenza ngakumbi kwaye kungenazimpazamo kunomatshini wemveli, ukuhlolwa komgangatho kusafuneka.Ukulawulwa komgangatho kunye nokuhlolwa kwenziwa kuwo onke amanqanaba okucubungula.Ukongezelela, ukuqinisekiswa komgangatho kubalulekile, okuyinkqubo yokuhlolwa komgangatho ebekwe yimibutho kunye nee-arhente ezigunyazisiweyo, kubandakanywa namaxwebhu ahambelanayo.Ulawulo lomgangatho lubalulekile kuwo onke amashishini, nokuba ziimveliso, iinxalenye, iinkqubo, izixhobo, okanye oomatshini.Ukuhlangabezana nokulindela kwabathengi, imigangatho yokurhweba, kunye nemimiselo yoshishino, i-Kachi isebenzisa izixhobo ezahlukeneyo zokulinganisa kunye nezixhobo zokulawula umgangatho we-CNC owenziwe ngomatshini oveliswe kwivenkile yethu yomatshini.

Eli nqaku lithetha ngokubaluleka kweengongoma ezi-6ukuhlolwa komgangathokunye neendlela ze-CNC zomatshini kunye neendlela zokulawula umgangatho.

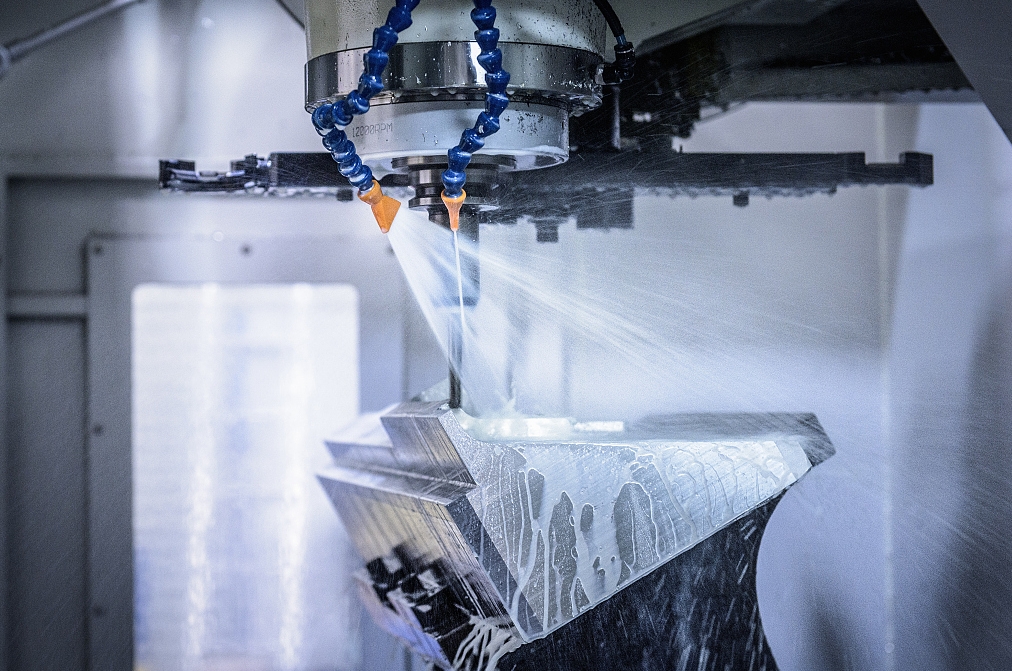

Iinkampani zoomatshini zeCNC zidlala indima ebalulekileyo kwimveliso yekhontrakthi kunye neenkonzo zokuchwetheza ngokukhawuleza.Impumelelo yale misebenzi ixhomekeke ekugcineni unyamezelo oluchane kakhulu, ngokufuthi kwinqanaba lemicroscopic.Ukubonisa oku, qwalasela ivalve yomgca wamafutha obungakanani bayo kufuneka bube ngaphakathi kwe-1 mm yobukhulu obuchaziweyo.Nakuphi na ukutenxa kule mfuneko kunokukhokelela ekuvuzeni kwe-oyile kumawaka ezithuthi.Iziphumo ezifanayo ebezingalindelekanga zinokwenzeka kumashishini afana ne-aerospace, ukwakhiwa kweenqanawa, kunye nokuveliswa kwezixhobo zombane.Ngoko ke, kubalulekile ukuphumeza amanyathelo okulawula umgangatho asebenzayo.

Ukuqinisekisa ukuba isixhobo siyakwazi ukuvelisa imveliso efunwayo okanye iprototype linyathelo lokuqala kulawulo lomgangatho.Izixhobo ze-CNC zibandakanya oomatshini abahlukeneyo, kubandakanya oomatshini bokucola, oomatshini bokungqusha, kunye noomatshini bokungqusha.Xa kuthengwa izixhobo, kucetyiswa ukuba ukhethe umthengisi ohloniphekileyo.Ukuba ukhetha ukuthenga izixhobo ezisetyenzisiweyo ngokuzithenga okanye ngokuziqeshisa, kufuneka ufake isicelo sewaranti.

Ulungelelwaniso rhoqo kunye nokuthotyelwa kwemigaqo yogcino zezinye zeendlela ezibaluleke kakhulu zokugcina imigangatho ekumgangatho ophezulu.Oomatshini banokuphulukana nokulinganisa ngenxa yokungcangcazela, ukothuka, kunye nezinye iziganeko kumzi-mveliso ojonge umgangatho.Ngelishwa, zininzi iiprothokholi zokulondolozwa kwee-spindles kwizixhobo ze-CNC.Nangona kunjalo, ukubabandakanya kwisicwangciso esibanzi sokugcinwa kunokuvelisa izibonelelo ezibalulekileyo ngokunciphisa ixesha lokuphumla.

Indima yokuhlola ngezandla ngokuthe ngcembe ithathelwa indawo okanye incediswe yinkqubela phambili yobuchwepheshe.Abavelisi banokusebenzisa ulawulo lwabo lomgangatho (QC) abasebenzi ukuba bahlole okanye bameme abavavanyi kwiifektri zabo ukuze bahlolwe.Ukugcinwa kweerekhodi sesinye isicwangciso esisebenzayo kwiivenkile ze-CNC ukuphucula umgangatho.Ngokurekhoda iziphumo zokuhlola kunye nokuzinikezela kwiigrafu okanye kwiitafile, abasebenzi be-QC banokufikelela ngokulula kwidatha kuwo wonke umatshini we-CNC kumgangatho wefektri.Oku kubavumela ukuba babeke iliso kwimiba eqhelekileyo kunye nengaqhelekanga.

Umgangatho womatshini we-CNC ekugqibeleni uxhomekeke kubuchule bomsebenzisi.Nangona kunjalo, okwangoku kukho izithuba zezakhono kubasebenzi, kubandakanywa ukunqongophala kwabaqhubi be-CNC.Esinye isisombululo kulo msantsa kukuba abavelisi benze ubambiswano namaziko emfundo ephakamileyo asekuhlaleni kwaye babonelele ngamathuba okufundela umsebenzi kwabo banqwenela ukuba ngabaqhubi be-CNC.

Isiqinisekiso se-ISO, esinje nge-ISO 9000, yi-asethi enexabiso kwiinkampani zomatshini ze-CNC.Ukufumana kunye nokugcina isatifikethi se-ISO kunokuphucula iinkqubo zoshishino, ukunciphisa i-scrap kunye nokusebenza kwakhona, kunye nokunciphisa iindleko.Ukongeza, isatifikethi se-ISO sisixhobo esinamandla sokuthengisa kunye nabasebenzi bezentengiso.Abanye abavelisi abaqinisekisiweyo be-ISO bade bafune nababoneleli babo ukuba nabo baqinisekiswe.

Kutheni kubalulekile ukulawula umgangatho?

Ulawulo lomgangatho luhlolo olubanzi lwemveliso kunye nenkqubo yokuvelisa.Kumatshini we-CNC, ulawulo lomgangatho lubalulekile ukuze kuqinisekiswe ukuba iimveliso ezenziweyo zihlangabezana nemigangatho yeshishini, ishishini, kunye neemfuno zabathengi.Ukongeza, ulawulo olululo lomgangatho wamacandelo e-CNC luya kuphepha iimveliso ezingalunganga, ukunciphisa imingcipheko, ukuqinisekisa ukuchaneka komgangatho kunye nomgangatho, ukonga izixhobo, ukunciphisa iindleko, kunye nokuphucula ukusebenza kakuhle.Oku kuyinto entle kubo bobabini abavelisi kunye nabathengi.

Ulwenza njani ulawulo lomgangatho?

Unxibelelwano lwabathengi

Unxibelelwano olusebenzayo lwabathengi luyinto ebalulekileyo ekuphumezeni ukwaneliseka kwabathengi.Ingaba ngexesha lenkqubo yokuvelisa okanye emva kokuthumela iisampuli, unxibelelwano olufike ngexesha kunye nabathengi lusebenza kakuhle.Abathengi kunye nabathengi baneemfuno ezicacileyo zenkcazo yemveliso kunye nemisebenzi.Xa sifumana umbuzo womthengi, siya kuqhagamshelana nomthengi ngokukhawuleza kwaye sinike i-quotation yamahhala ngokukhawuleza.Ukuba kukho ingxaki, siya kulungelelanisa isisombululo ngokukhawuleza.Nceda usazise kwangaphambili ukuba unazo naziphi na iimfuno ezikhethekileyo.

Qonda uyilo lwemveliso

Xa abathengi bethumela imizobo ye-CAD yeemveliso zokugqibela, iinjineli kufuneka zihlalutye uyilo ngokweenkcukacha, ziqonde iinkcukacha zemveliso yomthengi kunye neemfuno, kwaye zijonge zonke iinkcukacha phambi kwemveliso.Siza kusebenzisa esona sisombululo sinexabiso eliphantsi kumatshini inxalenye yakho, izinto zokulawula kuyo yonke inkqubo yomatshini ye-CNC, kunye nokuqinisekisa ukuba iimfuno ziyafezekiswa.

Iimveliso kunye neNkonzo

Iinkqubo zokubeka iliso kunye nemilinganiselo yazo zonke iimveliso ezichanekileyo zichazwe kwimizobo kunye neenkcukacha, iindlela zokuvelisa, amaxwebhu okuthenga, kunye neenkqubo zokuhlola kunye nokuvavanya.

Ukuqinisekiswa kwemveliso ethengiweyo

Zonke iimveliso ezithengiweyo zihlolwe ngokubonakalayo ngumhloli ofumanayo.Iimveliso ezikhethiweyo zikwaphantsi kolawulo oluneenkcukacha lobugcisa (QC) .

Ukuhlolwa kwenkqubo

Ukuhlolwa kwenkqubo kuthatha uhlobo lokuhlolwa kwenqaku lokuqala kunye nokuhlolwa kwabaqhubi ukuqinisekisa umgangatho kunye nokuhanjiswa kwangexesha kwee-odolo ezigqityiweyo kubathengi bethu.

Uvavanyo lokugqibela

Iimveliso ezigqityiweyo ze-CNC zihlolwa okokugqibela kwe-QC.Okokuqala, umhloli uqinisekisa ukuba lonke uhlolo oluchaziweyo kunye nokuhlolwa kwenkqubo kugqityiwe.Emva koko benza uhlolo oluseleyo kunye novavanyo ukugqiba isiqinisekiso sokuthotyelwa kwemveliso.Iziphumo zazo zonke iimvavanyo kunye neemvavanyo ziya kubhalwa, kwaye kuphela iimveliso eziphumelele inkqubo yokuhlola yokugqibela ziya kupakishwa kwaye zithunyelwe.

Abaqhubi baya kusingatha iindawo zokugqibela zoomatshini.Kukho izixhobo ezahlukeneyo zokulinganisa eziphambili ezikhoyo kwimilinganiselo yokuhlola emininzi njengobukhulu, ubunzima, umbala, ukunyamezela, njl.

Ixesha lokuposa: Nov-07-2023