The introduction of Computer Numerical Control (CNC) machines has significantly transformed the manufacturing industry, enabling the production of intricate and accurate parts with remarkable ease. By automating the machining process, CNC machines have not only enhanced efficiency but also improved the precision and consistency of manufacturing. This article aims to delve into the various types of CNC machines utilized in manufacturing, exploring their distinct features and the diverse array of parts they can produce.

#1 CNC Lathes and Turning Machines

CNC lathes and turning machines play a pivotal role in manufacturing due to their capacity to rotate materials during the machining process. The cutting tools move linearly along the rotating bar stock, eliminating material around the circumference until the desired diameter and feature are achieved. CNC lathes excel in fabricating internal and external features on components, including drilled holes, bores, reamed holes, slots, tapping, tapers, and threads. The components manufactured using CNC lathes and turning centers encompass screws, bolts, shafts, and poppets.

A subset of CNC lathes includes CNC Swiss lathes, which are operated by Pioneer Service. These lathes enable the bar of material to rotate and slide axially through a guide bushing, offering enhanced support for the material as the tooling machines the part features, resulting in tighter tolerances.

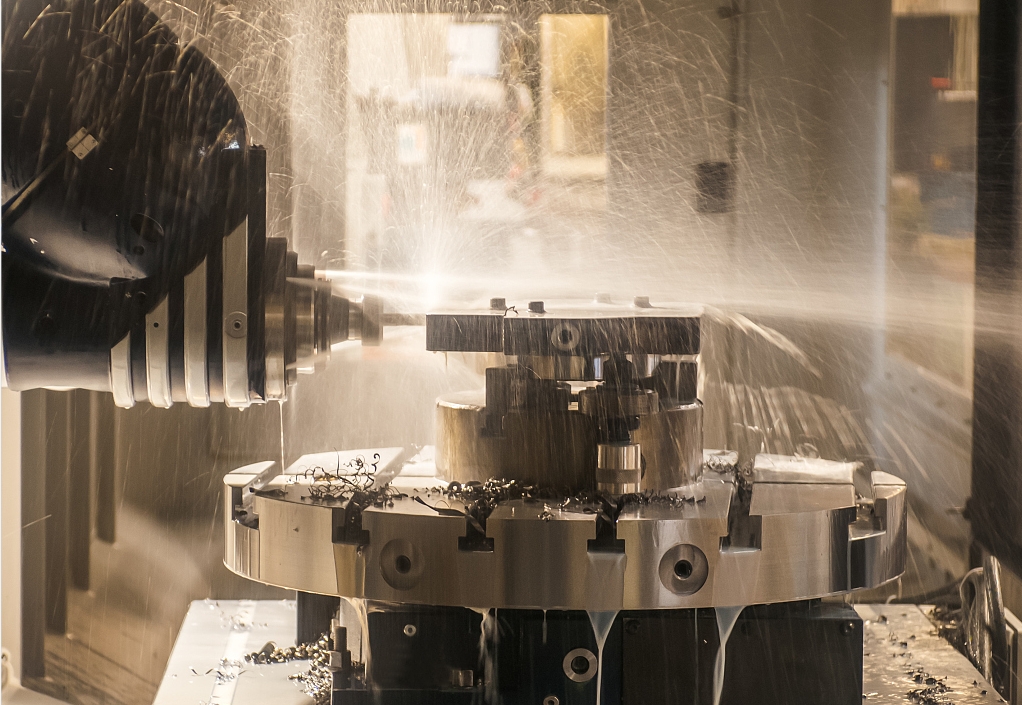

#2 CNC Milling Machines

Renowned for their ability to rotate cutting tools while holding the material workpiece/block stationary, CNC milling machines have the capability to produce a diverse range of shapes. This includes face-milled features such as shallow, flat surfaces and cavities in the workpiece, as well as peripheral milled features like deep cavities such as slots and threads. Components produced on CNC milling machines generally take the form of square or rectangular shapes with a variety of features.

#3 CNC Laser Machines

CNC laser machines are equipped with a pointed router featuring a highly focused laser beam used to precisely cut, slice, or engrave materials. The laser heats the material, causing it to melt or vaporize, thereby creating a cut. Typically used on materials in sheet format, the laser beam moves back and forth over the material to create a precise cut. This process allows for a wider range of designs compared to conventional cutting machines (lathes, turning centers, mills) and often produces cuts and/or edges that do not require additional finishing processes.

CNC laser engravers are frequently employed for part marking and decoration of machined components. For instance, while machining a logo and company name into a CNC-turned or CNC-milled component can be challenging, laser engraving can be utilized to add these details even after the machining operations are complete.

#4 CNC Electrical Discharge Machines (EDM)

A CNC electric discharge machine (EDM) utilizes highly controlled electrical sparks to manipulate materials into a desired shape. Also known as spark eroding, die sinking, spark machining, or wire burning, this process involves positioning a component under the electrode wire and emitting an electrical discharge from the wire, generating intense heat (up to 21,000 degrees Fahrenheit). The material is melted or flushed away with liquid to create the desired shape or feature. EDM is predominantly used to create precise micro holes, slots, tapered or angled features, and a variety of other intricate features in a component or work piece, especially for very hard metals that would be challenging to the machine to the desired shape or feature, such as a gear.

#5 CNC Plasma Cutting Machines

CNC plasma cutting machines are employed to cut materials using a high-powered plasma torch controlled by a computer. Similar in function to a handheld, gas-powered torch used for welding, plasma torches can achieve temperatures of up to 50,000 degrees Fahrenheit. The plasma torch melts through the work piece to create a cut in the material. It's important to note that anytime CNC plasma cutting is employed, the material being cut must be electrically conductive. Typical materials cut using CNC plasma cutting machines include steel, stainless steel, aluminum, brass, and copper.

# Conclusion

In conclusion, the advent of CNC machines has brought about a significant revolution in the manufacturing industry, enabling the production of complex and precise parts with remarkable ease. Each type of CNC machine, including lathes, milling machines, laser machines, EDMs, and plasma cutting machines, possesses unique features and capabilities for producing different parts. Understanding the capabilities of each machine is crucial in determining the optimal method for achieving the desired result. With precision CNC machining, the possibilities are truly endless.

Post time: Nov-15-2023