Is CNC Machining The Same Thing As 3D Printing?

Actually, they are not the same thing.

3D printing and CNC machining are both of manufacturing technologies, but they have very obvious different manufacturing processes that use distinct methods to create parts. The following explains their differences from several aspects.

(3D printing and CNC machining are distinct manufacturing technologies with different processes for creating parts.)

1.Technology

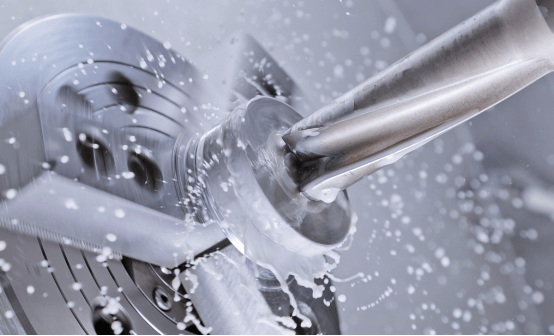

CNC machining is constructed by drilling, cutting, grinding, milling, cutting materials.

CNC machining is a subtraction manufacturing technology that uses a series of complex machines such as grinders, lathes, drills, routers, plasma cutters, laser cutters, and milling machines to remove excess parts from raw materials and create precision parts . CNC machining covers milling, turning, drilling and other services.

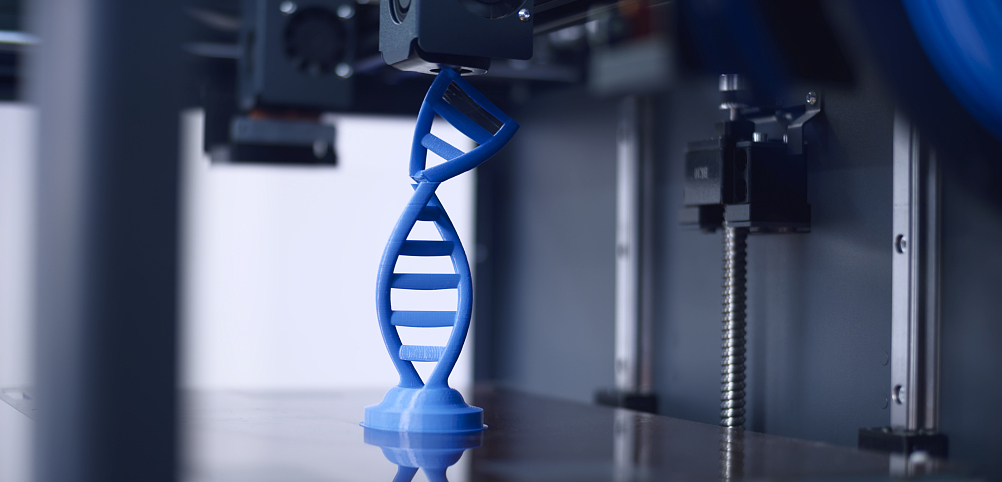

3D printing is construct by adding materials

Invented later than CNC, 3D printing is an additive manufacturing process that builds a 3D object from a computer-aided design (CAD) model by adding material layer by layer. 3D printing includes selective laser sinter, light curing molding, etc.

2.Goal

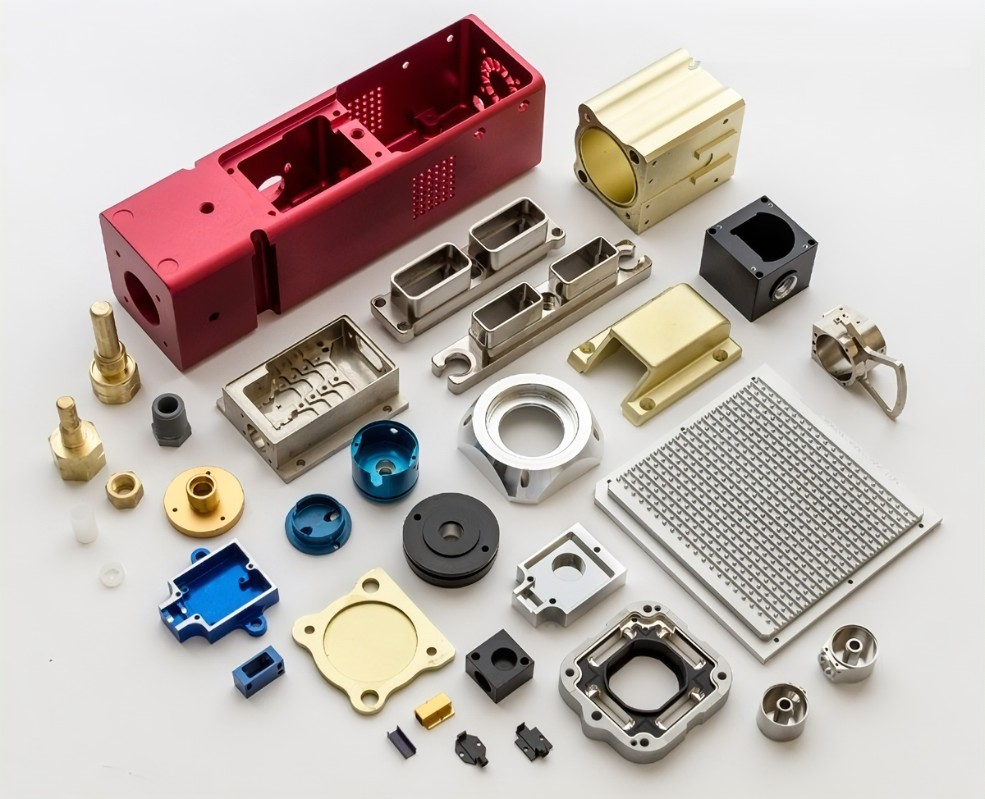

CNC machining: Precision and accuracy

CNC machining allows for extremely precise and accurate production. Computer control ensures that the machine follows programmed instructions to create parts with tight tolerances and high repeatability.And the primary goal of CNC machining is to automate and optimize the manufacturing process, ensuring precision, efficiency, and versatility in the production of parts and products.

3D printing: Wide range of customization

3D printing allows for the production of highly customized and unique objects. Designs can be easily tailored to individual requirements, making it ideal for personalized products and prototypes.

And the primary goal of 3D printing is to offer a versatile and efficient manufacturing process that can create customized, complex, and on-demand objects with a wide range of materials. It has revolutionized how products are designed, prototype, and manufactured, with applications spanning multiple industries and sectors.

3.Material

The material option of CNC machining more than 3D printing. 3D printing materials mainly include liquid resin, nylon powder, metal powder, etc. These three different materials are commonly used in industrial 3D printing. The most commonly used materials for CNC processing are metal sheets, but plastic sheets and wood can also be processed.

4.Waste material

CNC machining:High

CNC machining can generate more material waste than 3D printing. In CNC machining, a solid block of material is often used as the starting point, and material is removed to create the final part. This subtraction process generates chips or swarf as waste material.

In CNC machining, the material is subjected to cutting, milling, and drilling processes, which can produce more significant forces and may lead to the generation of heat. These processes can cause localized material damage, such as tool wear and surface imperfections.

3D printing:Low

3D printing is often more material-efficient compared to CNC machining. It adds material layer by layer, which minimizes waste, as there is little to no excess material. However, some material waste can occur due to factors like support structures and failed prints. And 3D printing is generally a gentler process for materials, as it doesn't involve high-speed cutting or high-temperature processes. However, the repeated application of heat (in the case of thermoplastic extrusion) and cooling can impact the material properties, potentially causing some degradation in mechanical properties.

5.Speed

CNC machining is generally faster than 3D printing for creating simple, small to medium-sized parts, especially when materials need to be removed or shaped quickly. 3D printing is typically slower due to its layer-by-layer additive process and is often used for complex or customized parts, rapid prototyping, and low-volume production where speed may not be the primary concern. However, it's important to note that the speed of both processes can be influenced by various parameters, and the choice between CNC machining and 3D printing should consider factors beyond just speed, such as material suitability, part complexity, and cost-effectiveness.

Conclusion :

CNC machining and 3D printing are two different manufacturing technologies, and their manufacturing processes and goals are obviously different.In short, depending on the specific requirements of the project, including materials, part complexity, tolerances, production volume and other factors, the choice of CNC machining or 3D printing needs to be comprehensively considered.

Post time: Nov-04-2023