Puas yog CNC Machining tib yam li 3D Printing?

Qhov tseeb, lawv tsis yog tib yam.

3D luam ntawv thiab CNC machining yog ob qho tib si ntawm kev tsim thev naus laus zis, tab sis lawv muaj cov txheej txheem tsim khoom sib txawv uas siv cov txheej txheem sib txawv los tsim cov khoom.Cov hauv qab no piav qhia lawv qhov sib txawv ntawm ntau yam.

(3D luam ntawv thiab CNC machining yog cov cuab yeej tsim khoom sib txawv nrog cov txheej txheem sib txawv rau kev tsim cov khoom.)

1.Technology

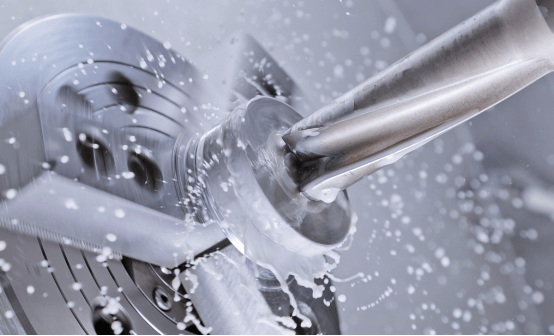

CNC machiningyog tsim los ntawm drilling, txiav, sib tsoo, milling, txiav cov ntaub ntawv.

CNC machiningyog lub tshuab rho tawm uas siv cov tshuab ua haujlwm nyuaj xws li grinders, lathes, laum, routers, plasma cutters, laser cutters, thiab milling machines kom tshem tawm cov khoom seem ntawm raw khoom thiab tsim precision qhov chaw.CNC machining npog milling, tig, drilling thiab lwm yam kev pabcuam.

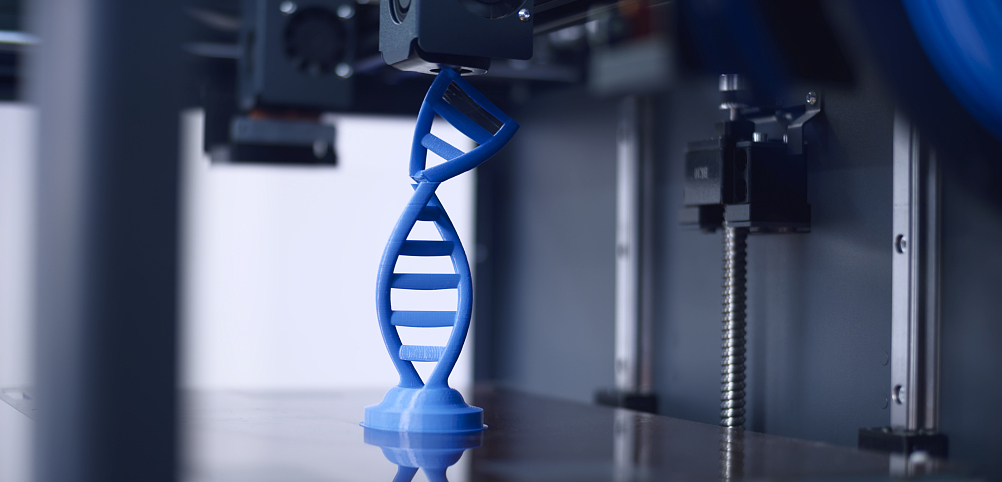

3D luam ntawvyog tsim los ntawm kev ntxiv cov ntaub ntawv

Invented tom qab CNC, 3D luam ntawv yog ib tug additive manufacturing txheej txheem uas tsim ib tug 3D khoom los ntawm lub computer-aided tsim (CAD) qauv los ntawm kev ntxiv cov khoom txheej los ntawm txheej.3D luam ntawv muaj xws li xaiv laser sinter, lub teeb curing molding, thiab lwm yam.

2. Lub hom phiaj

CNC machining: Precision thiab raug

CNC machining tso cai rau kev tsim khoom zoo heev thiab raug.Lub tshuab computer tswj xyuas kom meej tias lub tshuab ua raws li cov lus qhia los tsim cov khoom nrog nruj tolerances thiab siab repeatability.Thiab lub hom phiaj tseem ceeb ntawm CNC machining yog automate thiab optimize cov txheej txheem tsim, xyuas kom meej precision, efficiency, thiab versatility nyob rau hauv zus tau tej cov khoom thiab cov khoom.

3D luam ntawv: Ntau yam ntawm customization

3D luam ntawv tso cai rau kev tsim cov khoom tsim tshwj xeeb thiab tshwj xeeb.Cov qauv tsim tuaj yeem tsim tau yooj yim raws li tus neeg yuav tsum tau ua, ua rau nws zoo tagnrho rau cov khoom ntiag tug thiab cov qauv tsim.

Thiab lub hom phiaj tseem ceeb ntawm 3D luam ntawv yog muab cov txheej txheem tsim khoom muaj ntau yam thiab ua tau zoo uas tuaj yeem tsim cov khoom customized, complex, thiab raws li xav tau nrog ntau yam khoom siv.Nws tau hloov pauv li cas cov khoom tsim, qauv, thiab tsim, nrog rau kev siv ntau yam kev lag luam thiab kev lag luam.

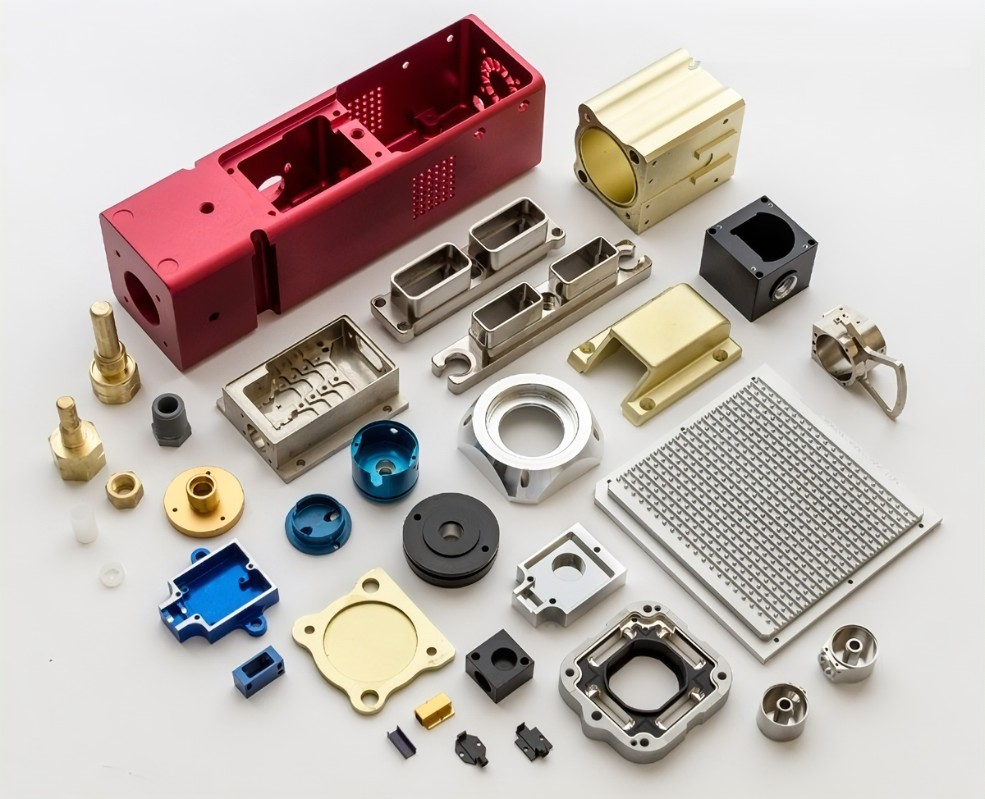

3. Khoom siv

Covcov khoom xaiv ntawm CNC machiningntau tshaj 3D luam ntawv.3D luam ntawv cov ntaub ntawv feem ntau muaj xws li cov kua resin, nylon hmoov, hlau hmoov, thiab lwm yam. Peb cov ntaub ntawv sib txawv no feem ntau siv hauv kev lag luam 3D luam ntawv.Cov khoom siv feem ntau siv rau kev ua CNC yoghlaunplooj ntawv, tab sis yas nplooj ntawv thiab ntoo kuj tuaj yeem ua tiav.

4. Cov khoom pov tseg

CNC machining: Siab

CNC machining tuaj yeem tsim cov khoom pov tseg ntau dua li 3D luam ntawv.Hauv CNC machining, ib qho khoom thaiv ntawm cov khoom siv feem ntau yog siv los ua qhov pib, thiab cov khoom raug tshem tawm los tsim qhov kawg.Cov txheej txheem rho tawm no tsim cov chips lossis swarf ua cov khoom pov tseg.

Hauv CNC machining, cov khoom yuav raug txiav, milling, thiab drilling txheej txheem, uas tuaj yeem tsim muaj zog ntau dua thiab tuaj yeem ua rau lub sijhawm cua sov.Cov txheej txheem no tuaj yeem ua rau muaj kev puas tsuaj rau cov khoom siv hauv zos, xws li cov cuab yeej hnav thiab qhov chaw tsis zoo.

3D luam ntawv: Tsawg

3D luam ntawv feem ntau yog cov khoom siv ntau dua piv rau CNC machining.Nws ntxiv cov ntaub ntawv txheej los ntawm txheej, uas txo cov pov tseg, vim tias tsis muaj cov khoom siv ntau dhau.Txawm li cas los xij, qee cov ntaub ntawv pov tseg tuaj yeem tshwm sim vim muaj yam xws li kev txhawb nqa cov qauv thiab cov ntawv luam tawm ua tsis tiav.Thiab 3D luam ntawv feem ntau yog cov txheej txheem maj mam rau cov ntaub ntawv, vim nws tsis cuam tshuam nrog kev txiav ceev lossis cov txheej txheem kub.Txawm li cas los xij, rov qab thov cov cua sov (nyob rau hauv cov ntaub ntawv ntawm thermoplastic extrusion) thiab cua txias tuaj yeem cuam tshuam cov khoom siv, uas ua rau qee qhov degradation hauv cov khoom siv tshuab.

5. Ceev

CNC machining feem ntau sai dua 3D luam ntawv rau kev tsim cov khoom yooj yim, me me mus rau nruab nrab qhov loj me, tshwj xeeb tshaj yog thaum cov ntaub ntawv yuav tsum tau muab tshem tawm lossis zoo li sai tau.3D luam ntawv feem ntau qeeb qeeb vim nws txheej txheej txheej txheej txheej txheej thiab feem ntau yog siv rau qhov nyuaj lossis kho qhov chaw, kev tsim qauv sai, thiab cov khoom ntim qis uas ceev yuav tsis yog thawj qhov kev txhawj xeeb.Txawm li cas los xij, nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias qhov ceev ntawm ob txoj kev tuaj yeem cuam tshuam los ntawm ntau yam tsis sib xws, thiab kev xaiv ntawm CNC machining thiab 3D luam ntawv yuav tsum xav txog ntau tshaj qhov ceev, xws li cov khoom tsim nyog, ib feem complexity, thiab nqi-zoo.

Xaus:

CNC machining thiab 3D luam ntawv yog ob txoj kev tsim khoom sib txawv, thiab lawv cov txheej txheem tsim khoom thiab cov hom phiaj yog qhov sib txawv.Nyob rau hauv luv luv, nyob ntawm seb cov kev xav tau tshwj xeeb ntawm qhov project, nrog rau cov ntaub ntawv, ib feem complexity, tolerances, ntau lawm ntim thiab lwm yam, kev xaiv ntawm CNC machining lossis 3D luam ntawv yuav tsum tau txiav txim siab.

Post lub sij hawm: Nov-04-2023