Shin CNC Machining abu ɗaya ne da Buga 3D?

A gaskiya, ba abu ɗaya ba ne.

3D bugu da CNC machining duka biyu na masana'antu fasahar, amma suna da a fili daban-daban masana'antu tafiyar matakai da yin amfani da daban-daban hanyoyi don ƙirƙirar sassa.Mai zuwa yana bayyana bambance-bambancen su daga bangarori da yawa.

(Buga 3D da injina na CNC sune fasahohin masana'antu daban-daban tare da matakai daban-daban don ƙirƙirar sassa.)

1.Fasahar

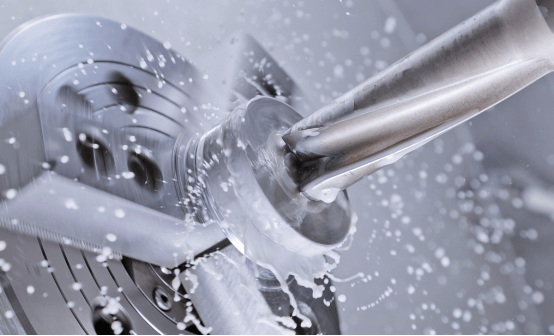

Injin CNCan gina shi ta hanyar hakowa, yankan, niƙa, niƙa, kayan yankan.

Injin CNCfasaha ce ta keɓancewa wacce ke amfani da jerin injunan hadaddun injuna kamar injin niƙa, lathes, drills, masu ba da hanya tsakanin hanyoyin sadarwa, masu yankan plasma, masu yankan Laser, da injunan niƙa don cire ɓangarorin da suka wuce kima daga albarkatun ƙasa da ƙirƙirar sashe daidai.CNC machining rufe niƙa, juyawa, hakowa da sauran ayyuka.

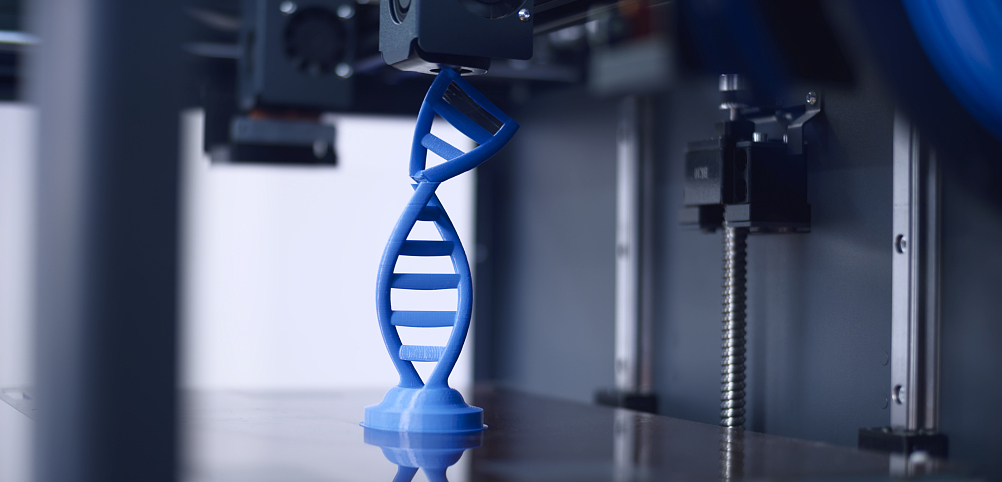

3D buguana gina ta ta hanyar ƙara kayan aiki

Ƙirƙirar ƙirƙira daga baya fiye da CNC, 3D bugu wani ƙari ne na masana'anta wanda ke gina abu na 3D daga ƙirar ƙira mai taimakon kwamfuta (CAD) ta ƙara Layer Layer Layer.3D bugu ya haɗa da zaɓaɓɓen laser sinter, haske curing gyare-gyare, da dai sauransu.

2.Manufa

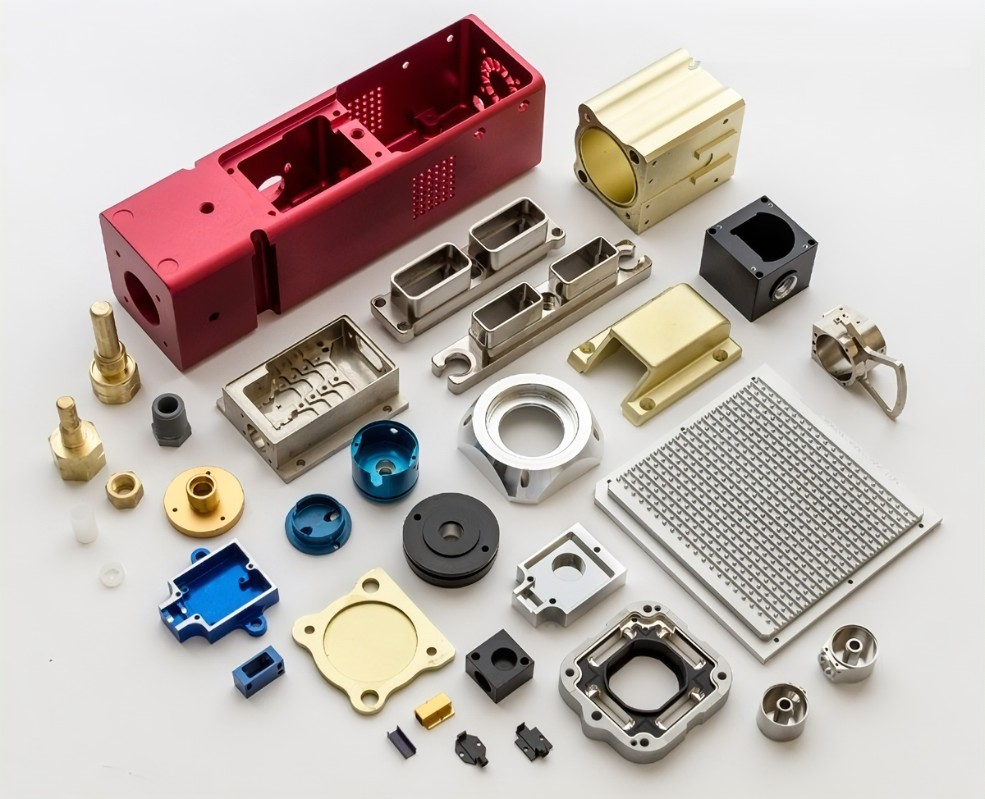

Injin CNC: daidaito da daidaito

CNC machining yana ba da damar samar da daidaitattun daidaito da daidaito.Kwamfuta kula da tabbatar da cewa inji ya bi shirye-shirye umarnin don ƙirƙirar sassa tare da m tolerances da high repeatability.And babban burin CNC machining shi ne don sarrafa kansa da kuma inganta masana'antu tsari, tabbatar da daidaito, yadda ya dace, da kuma versatility a samar da sassa da kayayyakin.

3D bugu: Faɗin keɓancewa

3D bugu yana ba da damar samar da abubuwa na musamman da na musamman.Za a iya keɓance ƙira cikin sauƙi ga buƙatun mutum ɗaya, yana mai da shi manufa don samfuran keɓaɓɓu da samfura.

Kuma babban makasudin bugu na 3D shine bayar da ingantaccen tsari mai inganci wanda zai iya ƙirƙirar abubuwan da aka keɓance, hadaddun, da abubuwan buƙatu tare da abubuwa masu yawa.Ya kawo sauyi yadda aka tsara samfuran, samfuri, da ƙera su, tare da aikace-aikacen da suka mamaye masana'antu da sassa da yawa.

3.Material

TheZaɓin kayan aikin CNC machiningfiye da 3D bugu.3D bugu kayan yafi hada da ruwa guduro, nailan foda, karfe foda, da dai sauransu Wadannan uku daban-daban kayan da aka saba amfani da masana'antu 3D bugu.Abubuwan da aka fi amfani da su don sarrafa CNC sunekarfezanen gado, amma filastik Za a iya sarrafa zanen gado da itace.

4.Sharar gida

Injin CNC: Babban

CNC machining iya samar da karin kayan sharar gida fiye da 3D bugu.A cikin mashin ɗin CNC, ana amfani da ƙaƙƙarfan shinge na abu sau da yawa azaman wurin farawa, kuma ana cire kayan don ƙirƙirar ɓangaren ƙarshe.Wannan tsarin cirewa yana haifar da kwakwalwan kwamfuta ko swarf azaman kayan sharar gida.

A cikin mashin ɗin CNC, ana aiwatar da kayan aikin yankan, niƙa, da hakowa, wanda zai iya haifar da ƙarin ƙarfi kuma yana iya haifar da haɓakar zafi.Waɗannan matakai na iya haifar da lalacewar kayan da aka keɓance, kamar lalacewa na kayan aiki da rashin lahani.

3D bugu: Kasa

3D bugu sau da yawa ya fi dacewa da kayan aiki idan aka kwatanta da injinan CNC.Yana ƙara kayan abu ta Layer, wanda ke rage sharar gida, saboda babu ɗan abin wuce gona da iri.Duk da haka, wasu sharar gida na iya faruwa saboda dalilai kamar tsarin tallafi da gazawar kwafi.Kuma bugu na 3D gabaɗaya tsari ne mai sauƙi don kayan aiki, saboda ba ya haɗa da yanke saurin sauri ko matakan zafi.Koyaya, maimaita aikace-aikacen zafi (a cikin yanayin extrusion thermoplastic) da sanyaya na iya yin tasiri ga kaddarorin kayan, mai yuwuwar haifar da lalacewa a cikin kayan injin.

5.Guri

CNC machining gabaɗaya sauri fiye da bugu na 3D don ƙirƙirar sassauƙa, ƙanana zuwa sassa masu girma, musamman lokacin da ake buƙatar cire kayan ko siffa da sauri.3D bugu yawanci yana sannu a hankali saboda tsarin ƙari na Layer-by-Layer kuma ana amfani dashi sau da yawa don hadaddun sassa ko keɓancewa, saurin samfuri, da samar da ƙananan ƙaranci inda gudun ƙila ba shine babban abin damuwa ba.Koyaya, yana da mahimmanci a lura cewa saurin tafiyar matakai biyu na iya yin tasiri ta sigogi daban-daban, kuma zaɓi tsakanin mashin ɗin CNC da bugu na 3D yakamata suyi la'akari da abubuwan da suka wuce saurin kawai, kamar dacewa da kayan aiki, haɓakar sashi, da ƙimar farashi.

Kammalawa:

CNC machining da 3D bugu ne biyu daban-daban masana'antu fasahar, da kuma masana'antu matakai da kuma manufofin ne a fili daban-daban.A takaice dai, dangane da takamaiman bukatun na aikin, ciki har da kayan, part complexity, tolerances, samar girma da sauran dalilai, da zabi na. CNC machining ko 3D bugu yana buƙatar yin la'akari sosai.

Lokacin aikawa: Nuwamba-04-2023