Ingabe i-CNC Machining Ifana Nokuphrinta kwe-3D?

Empeleni, azifani.

Ukuphrinta kwe-3D kanye nemishini ye-CNC yomibili yobuchwepheshe bokukhiqiza, kodwa inezinqubo zokukhiqiza ezisobala kakhulu ezisebenzisa izindlela ezihlukile zokwakha izingxenye.Okulandelayo kuchaza umehluko wabo ezicini eziningana.

(Ukuphrinta kwe-3D kanye nemishini ye-CNC ubuchwepheshe bokukhiqiza obuhlukile obunezinqubo ezihlukene zokudala izingxenye.)

1.Ubuchwepheshe

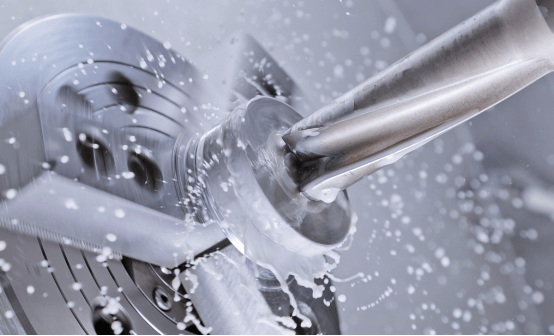

CNC imishiniyakhiwa ngokubhoboza, ukusika, ukugaya, ukugaya, izinto zokusika.

CNC imishiniubuchwepheshe bokukhiqiza obukhiphayo obusebenzisa uchungechunge lwemishini eyinkimbinkimbi efana nezigayo, izinsimbi, izimbobo, amarutha, ama-plasma cutter, ama-laser cutter, nemishini yokugaya ukuze kususwe izingxenye ezingaphezulu ezintweni ezingavuthiwe nokudala izingxenye ezinembayo .Imishini ye-CNC ihlanganisa ukugaya, ukujika, ukubhola nezinye izinsiza.

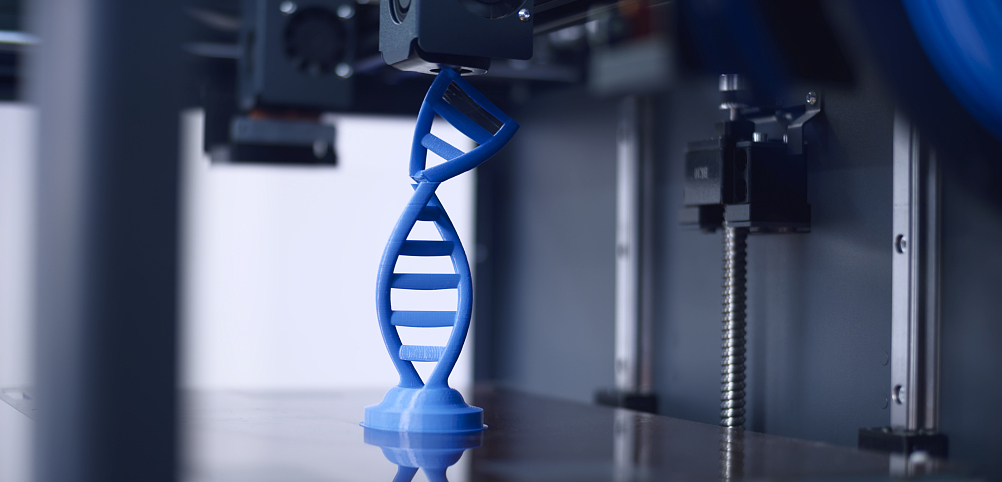

Ukuphrinta kwe-3Dyakhiwa ngokungeza izinto zokwakha

Kuqanjwe kamuva kune-CNC, ukuphrinta kwe-3D kuyinqubo yokukhiqiza okungeziwe eyakha into ye-3D kusukela kumodeli yomklamo osizwa ngekhompuyutha (i-CAD) ngokwengeza isendlalelo esibalulekile ngokwesendlalelo.Ukuphrinta kwe-3D kufaka phakathi i-laser sinter ekhethiwe, ukubumba okupholisa ukukhanya, njll.

2.Igoli

CNC imishini: Ukunemba nokunemba

Imishini ye-CNC ivumela ukukhiqizwa okunembe kakhulu nokunembile.Ukulawulwa kwekhompyutha kuqinisekisa ukuthi umshini ulandela imiyalelo ehleliwe ukuze udale izingxenye ezinokubekezelelana okuqinile nokuphindaphindwa okuphezulu.Futhi umgomo oyinhloko womshini we-CNC uwukwenza ngokuzenzakalelayo nokuthuthukisa inqubo yokukhiqiza, ukuqinisekisa ukunemba, ukusebenza kahle, kanye nokuguquguquka ekukhiqizeni izingxenye nemikhiqizo.

3D ukuphrinta: Ibanga elibanzi lokwenza ngokwezifiso

Ukuphrinta kwe-3D kuvumela ukukhiqizwa kwezinto ezenziwe ngokwezifiso kakhulu neziyingqayizivele.Imiklamo ingavunyelaniswa kalula nezidingo zomuntu ngamunye, iyenze ilungele imikhiqizo yomuntu siqu kanye nama-prototypes.

Futhi umgomo oyinhloko wokuphrinta kwe-3D ukunikeza inqubo yokukhiqiza eguquguqukayo nephumelelayo engakha izinto ezenziwe ngokwezifiso, eziyinkimbinkimbi, nezidingeka kakhulu ezinohlu olubanzi lwezinto.Iguqule indlela imikhiqizo eklanywa ngayo, i-prototype, kanye nokukhiqizwa ngayo, ngezinhlelo zokusebenza ezihlanganisa izimboni nemikhakha eminingi.

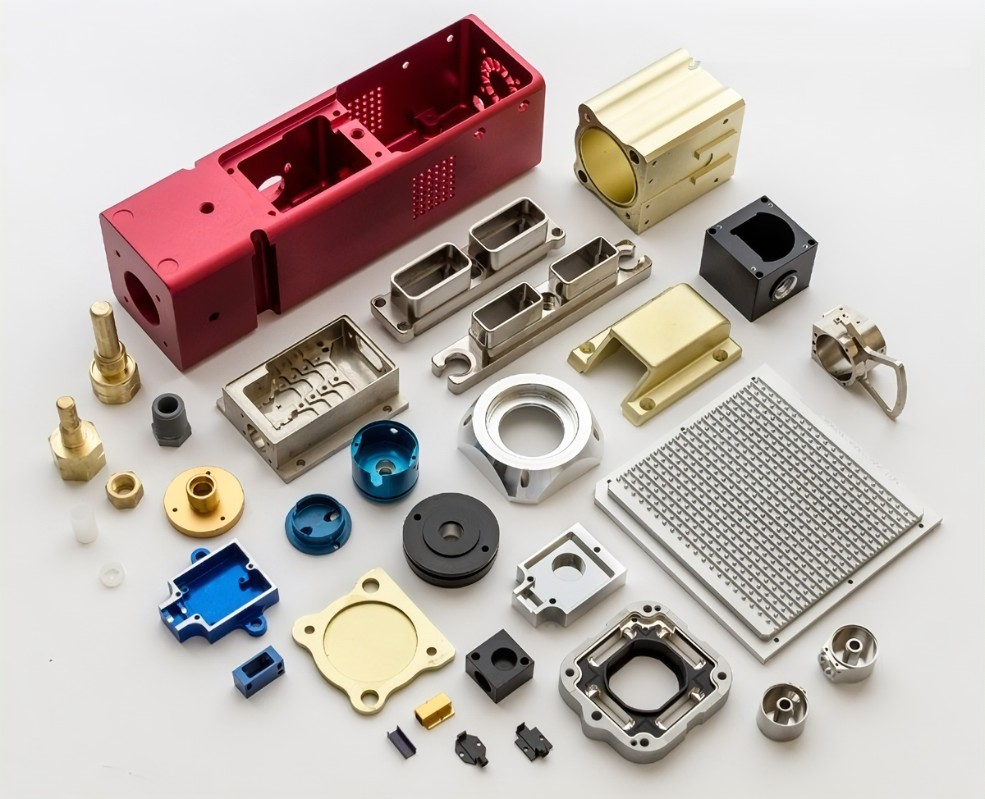

3.Impahla

Iinketho impahla CNC machiningukuphrinta okungaphezu kwe-3D.Izinto zokuphrinta ze-3D ikakhulukazi zifaka inhlaka ewuketshezi, impushana enayiloni, impushana yensimbi, njll. Lezi zinto ezintathu ezihlukene zivame ukusetshenziswa ekunyatheliseni kwe-3D yezimboni.Izinto ezisetshenziswa kakhulu zokucubungula i-CNC ziyiinsimbiamashidi, kodwa ipulasitiki amashidi nezinkuni nakho kungacutshungulwa.

4.Waste material

CNC imishini:Phezulu

Imishini ye-CNC ingakhiqiza imfucuza yezinto ezibonakalayo ngaphezu kokuphrinta kwe-3D.Ekwenziweni kwemishini ye-CNC, ibhulokhi eqinile yezinto ivamise ukusetshenziswa njengendawo yokuqala, futhi impahla iyasuswa ukuze kwakhiwe ingxenye yokugcina.Le nqubo yokukhipha ikhiqiza ama-chips noma ama-swarf njengempahla eyimfucuza.

Emishinini ye-CNC, izinto ezisetshenziswayo zingaphansi kwezinqubo zokusika, ukugaya, nokumba, ezingakhiqiza amandla abaluleke kakhulu futhi ezingaholela ekukhiqizeni ukushisa.Lezi zinqubo zingabangela umonakalo wendawo, njengokuguga kwamathuluzi nokungapheleli kwendawo.

Ukuphrinta kwe-3D:Phansi

Ukuphrinta kwe-3D kuvame ukusebenza kahle ngokwezinto ezibonakalayo uma kuqhathaniswa nemishini ye-CNC.Yengeza ungqimba lwempahla ngongqimba, okunciphisa imfucuza, njengoba kuncane noma kungabibikho okweqile.Nokho, enye imfucumfucu yezinto ezibonakalayo ingenzeka ngenxa yezinto ezifana nezakhiwo zokusekela kanye nokuphrinta okuhlulekile.Futhi ukuphrinta kwe-3D ngokuvamile kuyinqubo ethambile yezinto zokwakha, njengoba ingabandakanyi izinqubo zokusika ngesivinini esiphezulu noma izinga lokushisa eliphezulu.Kodwa-ke, ukusetshenziswa okuphindaphindiwe kokushisa (esimeni se-thermoplastic extrusion) kanye nokupholisa kungase kube nomthelela ezintweni ezibonakalayo, okungase kubangele ukuwohloka okuthile ezicini zokuwumshini.

5.Isivinini

Ukunyathelisa kwe-CNC kuvame ukushesha kunokuphrinta kwe-3D ngokudala izingxenye ezilula, ezincane ukuya ezimaphakathi, ikakhulukazi uma izinto ezisetshenziswayo zidinga ukususwa noma ukulolongwa ngokushesha.Ukuphrinta kwe-3D ngokuvamile kuhamba kancane ngenxa yenqubo yakho yokwengeza isendlalelo nesendlalelo futhi kuvame ukusetshenziselwa izingxenye eziyinkimbinkimbi noma ezenziwe ngokwezifiso, i-prototyping esheshayo, nokukhiqizwa kwevolumu ephansi lapho isivinini singase singabi yinto ekhathaza kakhulu.Kodwa-ke, kubalulekile ukuqaphela ukuthi isivinini sazo zombili izinqubo singathonywa amapharamitha ahlukahlukene, futhi ukukhetha phakathi komshini we-CNC nokuphrinta kwe-3D kufanele kucabangele izici ezingaphezu kwesivinini nje, njengokufaneleka kwezinto, ingxenye eyinkimbinkimbi, kanye nokusebenza kahle kwezindleko.

Isiphetho:

I-CNC machining kanye nokunyathelisa kwe-3D ubuchwepheshe obuhlukene bokukhiqiza, futhi izinqubo zabo zokukhiqiza kanye nezinhloso zihlukile ngokusobala. Imishini ye-CNC noma ukuphrinta kwe-3D kudinga ukucatshangelwa ngokuphelele.

Isikhathi sokuthumela: Nov-04-2023