Imikhiqizo

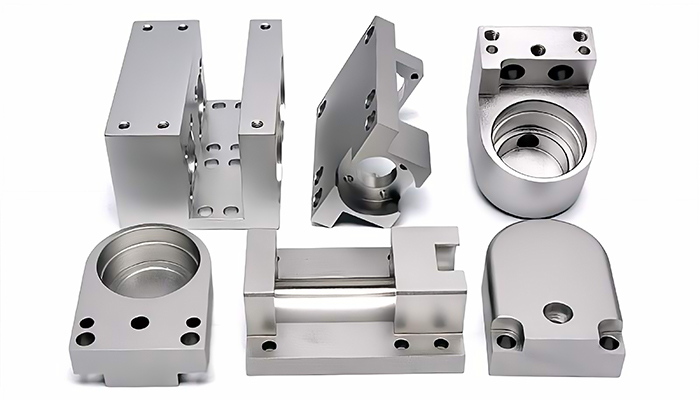

CNC Machining in Aluminium

CNC Machining In Alloy

Izinsimbi ze-alloy, ezihlanganisa izakhi ezengeziwe ze-alloying kanye nekhabhoni, zibonisa ubulukhuni obuthuthukisiwe, ukuqina, ukumelana nokukhathala, nokumelana nokuguga.

Izinto ze-alloys zivame ukusetshenziswa kuzinqubo zemishini ye-CNC.

Imishini ye-CNC yenza kube lula ukukhiqizwa kwezingxenye zesimanje kusetshenziswa izinto zensimbi ye-alloy, ebonisa izakhiwo eziphakeme zemishini, izilinganiso ezinembile kanye nemiphumela enokwethenjelwa.Izinketho zenqubo yomshini zifaka phakathi i-3-eksisi kanye ne-5-eksisi ye-CNC yokugaya ukwandisa ukuguquguquka kokukhiqiza kanye nokuguquguquka.

Isicelo

I-CNC machining iyinqubo enokwethenjelwa yokukhiqiza izingxenye eziphezulu ezivela ezintweni zensimbi nezepulasitiki.Iqinisekisa izici ezinhle kakhulu zemishini, izilinganiso ezinembile kanye nemiphumela engaguquki.Ngaphezu kwalokho, siphinde sinikeze ukugaya okuguquguqukayo kwe-3-eksisi kanye ne-5-eksisi ye-CNC ukuze kuhlangatshezwane nezidingo zokukhiqiza ezihlukene.

Izinzuzo

Izakhiwo ezisezingeni eliphakeme zemishini ye-CNC machining ziqinisekisa ukuqina kanye nekhwalithi yezingxenye ezikhiqizayo.Inikeza ukunemba okuhlaba umxhwele nokuphindaphinda, iqinisekisa imiphumela enembile nengaguquguquki kuyo yonke inqubo yokukhiqiza.

Ukubi

Uma kuqhathaniswa nokuphrinta kwe-3D, ukwenza imishini ye-CNC kubeka izithiyo ezengeziwe kunkimbinkimbi yejiyomethri efinyelelekayo, ekugcineni kunciphisa ububanzi bamathuba edizayini atholakalayo.

Inani

$$$$$

Isikhathi esiholayo

< 2 izinsuku

Ukuqina Kwezindonga

0.75mm

Ukubekezelelana

±0.125mm (±0.005″)

Ubukhulu bengxenye yosayizi

200 x 80 x 100 cm

Ayini ama-alloys

Ama-alloys yizinto zensimbi ezenziwe ngokuhlanganisa izakhi ezimbili noma ngaphezulu, okungenani eyodwa yazo iyinsimbi.Inhlanganisela yezakhi ezahlukene inikeza izici ezithile ku-alloy ehlukile kulezo zezakhi ngazinye.

Izinhlobo zama-alloys:

Kunezinhlobo eziningana zama-alloys ngokusekelwe ezintweni eziqukethe kanye nezakhiwo zazo.Ezinye izinhlobo ezijwayelekile zihlanganisa:

- Insimbi:Insimbi iyingxubevange yensimbi nekhabhoni, okuqukethwe kwekhabhoni kuvame ukusukela ku-0.2% kuya ku-2.1%.Yaziwa ngamandla ayo aphezulu, ukuqina, nokuguquguquka.Insimbi ingabuye ihlanganiswe nezinye izakhi ukuze kuthuthukiswe izakhiwo ezithile.

- Insimbi engagqwali:Insimbi engagqwali iyingxubevange yensimbi, i-chromium, futhi ngezinye izikhathi nezinye izakhi ezifana ne-nickel noma i-molybdenum.Iyakwazi ukumelana nokugqwala, okuyenza ifanelekele ukusetshenziswa lapho kudingeka ukumelana nokugqwala kanye nokubanda.

- Aluminium alloys:Ama-alloys e-aluminium enziwa ngokuhlanganisa i-aluminium nezinye izakhi ezifana nethusi, i-zinc, i-magnesium, noma i-silicon.Lawa ma-alloys anikeza ibhalansi enhle yamandla, izakhiwo ezingasindi, nokumelana nokugqwala.Asetshenziswa kakhulu ezimbonini ezifana ne-aerospace, ezezimoto, nezokwakha.

- Izingxube ze-Titanium:Ama-alloys e-Titanium enziwa ngokuhlanganisa i-titanium nezinye izakhi ezifana ne-aluminium, i-vanadium, noma insimbi.Baziwa ngesilinganiso sabo esiphezulu samandla nesisindo, ukumelana nokugqwala okuhle kakhulu, kanye ne-biocompatibility.Ama-alloys e-Titanium avame ukusetshenziswa ezimbonini ze-aerospace, zezokwelapha, namakhemikhali.

Izakhiwo nezinzuzo:

Ama-alloys ngokuvamile abonisa izakhiwo ezithuthukisiwe uma kuqhathaniswa nezinsimbi ezihlanzekile.Lezi zakhiwo zingabandakanya amandla akhulayo, ukuqina, ukumelana nokugqwala, ukumelana nokushisa, kanye nokuhamba kukagesi.Ama-alloys nawo angafanelana nezinhlelo zokusebenza ezithile ngokulungisa ukwakheka kanye namasu okucubungula.

Izicelo:

Ama-alloys anohlu olubanzi lwezinhlelo zokusebenza kuzo zonke izimboni ezahlukahlukene.Isibonelo, insimbi isetshenziswa emikhakheni yezokwakha, yezimoto, neyokukhiqiza.Insimbi engagqwali ivame ukutholakala ezintweni zikagesi zasekhishini, amathuluzi ezokwelapha, namathuluzi okucubungula amakhemikhali.Ama-alloys e-aluminium asetshenziswa ezindizeni, ezimotweni, nasekupakisheni.Ama-alloys e-Titanium athola ukusetshenziswa ku-aerospace, izimila zezokwelapha, namathuluzi ezemidlalo.

Izinqubo zokukhiqiza:

Ama-alloys angakhiqizwa ngezindlela ezahlukahlukene, kufaka phakathi ukubunjwa, ukubumba, ukukhishwa, kanye ne-powder metallurgy.Ukukhethwa kwenqubo yokukhiqiza kuncike ku-alloy ethile kanye nezakhiwo ezifunwayo.