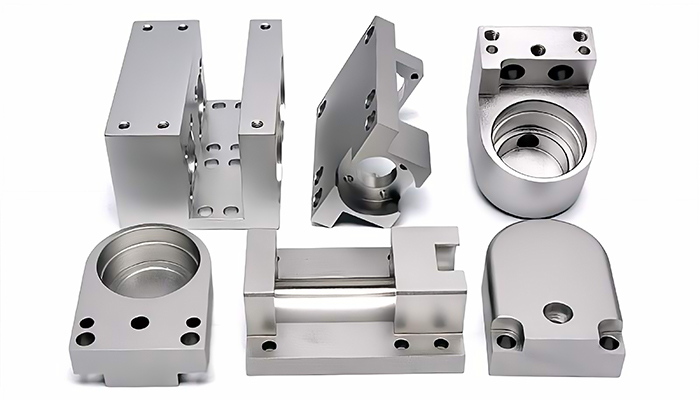

Cov khoom

CNC Machining nyob rau hauv Aluminium

CNC Machining nyob rau hauv Alloy

Alloy steels, uas muaj cov ntsiab lus alloying ntxiv nrog rau cov pa roj carbon monoxide, ua kom muaj zog hardness, toughness, qaug zog tsis kam, thiab hnav tsis kam.

Cov ntaub ntawv alloys feem ntau siv hauv CNC machining txheej txheem.

CNC machining enables zus tau tej cov khoom nyob rau hauv lub xeev-of-the-kos duab siv cov ntaub ntawv hlau alloy, exhibiting superior mechanical zog, meej ntsuas thiab txhim khu kev qha tau.Machining txheej txheem kev xaiv muaj xws li 3-axis thiab 5-axis CNC milling rau kev tsim khoom ntau thiab yooj yim.

Daim ntawv thov

CNC machining yog txheej txheem txhim khu kev qha rau kev tsim cov khoom zoo ntawm cov khoom siv hlau thiab yas.Nws ua kom cov khoom siv kho tshuab zoo heev, kev ntsuas meej thiab cov txiaj ntsig zoo ib yam.Tsis tas li ntawd, peb kuj muab kev hloov pauv 3-axis thiab 5-axis CNC milling kom tau raws li kev tsim khoom sib txawv.

Qhov zoo

Lub superior mechanical zog ntawm CNC machining lav lub durability thiab zoo ntawm cov khoom nws tsim.Nws muab qhov tseeb qhov tseeb thiab rov ua dua, ua kom cov txiaj ntsig zoo thiab zoo ib yam thoob plaws hauv cov txheej txheem tsim khoom.

Qhov tsis zoo

Piv nrog rau 3D luam ntawv, CNC machining qhov chaw muaj ntau qhov kev txwv ntawm qhov ua tiav geometric complexity, thaum kawg txo qhov ntau ntawm cov tsim muaj peev xwm.

Nqe

$$$$$

Lub Sijhawm Lead

<2 hnub

Phab ntsa Thickness

0.75mm ib

Kev kam rau siab

± 0.125 hli (± 0.005 ″)

Max qhov loj me

200 x 80 x 100 cm

Dab tsi yog alloys

Alloys yog cov khoom siv hlau uas yog tsim los ntawm kev sib txuas ob lossis ntau lub ntsiab lus, nrog tsawg kawg ib qho ntawm lawv yog hlau.Kev sib xyaw ntawm cov khoom sib txawv imparts cov khoom tshwj xeeb rau cov hlau uas txawv ntawm cov khoom ntawm tus kheej.

Hom alloys:

Muaj ntau ntau hom alloys raws li cov khoom uas lawv muaj thiab lawv cov khoom.Qee hom muaj xws li:

- Hlau:Cov hlau yog cov hlau thiab cov pa roj carbon, nrog cov ntsiab lus carbon feem ntau yog li ntawm 0.2% mus rau 2.1%.Nws yog lub npe hu rau nws lub zog siab, durability, thiab versatility.Hlau kuj tuaj yeem ua alloyed nrog lwm cov ntsiab lus los txhim kho cov khoom tshwj xeeb.

- Stainless hlau:Stainless hlau yog ib qho alloy ntawm hlau, chromium, thiab qee zaum lwm yam xws li nickel lossis molybdenum.Nws yog heev corrosion-resistant, ua rau nws haum rau daim ntaub ntawv uas yuav tsum tau tiv thaiv xeb thiab staining.

-Aluminium alloys:Aluminium alloys yog tsim los ntawm kev sib txuas ntawm txhuas nrog lwm cov khoom xws li tooj liab, zinc, magnesium, lossis silicon.Cov alloys no muaj qhov sib npaug zoo ntawm lub zog, lub teeb yuag, thiab tiv thaiv corrosion.Lawv tau siv dav hauv kev lag luam xws li aerospace, automotive, thiab kev tsim kho.

- Titanium alloys:Titanium alloys yog tsim los ntawm kev sib txuas titanium nrog lwm cov khoom xws li txhuas, vanadium, lossis hlau.Lawv paub txog lawv lub zog-rau-qhov hnyav piv, zoo heev corrosion kuj, thiab biocompatibility.Titanium alloys feem ntau siv hauv aerospace, kev kho mob, thiab tshuaj lom neeg kev lag luam.

Khoom thiab qhov zoo:

Alloys feem ntau nthuav tawm cov khoom zoo dua qub piv rau cov hlau ntshiab.Cov khoom no muaj xws li muaj zog, hardness, corrosion kuj, kub tsis kam, thiab hluav taws xob conductivity.Alloys kuj tuaj yeem raug kho raws li cov ntawv thov tshwj xeeb los ntawm kev kho cov khoom sib xyaw thiab cov txheej txheem ua haujlwm.

Daim ntawv thov:

Alloys muaj ntau yam kev siv thoob plaws ntau yam kev lag luam.Piv txwv li, steel yog siv nyob rau hauv kev tsim kho, automotive, thiab manufacturing sectors.Stainless hlau feem ntau pom muaj nyob rau hauv cov khoom siv hauv chav ua noj, cov cuab yeej kho mob, thiab cov khoom siv tshuaj.Aluminium alloys yog siv rau hauv dav hlau, tsheb, thiab ntim khoom.Titanium alloys pom cov ntawv thov hauv aerospace, kho mob cog, thiab cov khoom ua si.

Cov txheej txheem tsim khoom:

Alloys tuaj yeem tsim los ntawm ntau txoj hauv kev, suav nrog casting, forging, extrusion, thiab hmoov metallurgy.Kev xaiv ntawm kev tsim khoom yog nyob ntawm qhov tshwj xeeb alloy thiab cov khoom xav tau.