Iimveliso

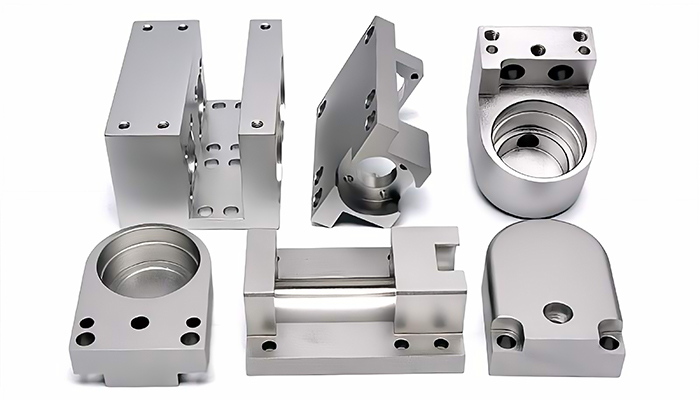

CNC Machining in Aluminiyam

CNC Machining Kwingxubevange

Iintsimbi ze-alloy, ezibandakanya izinto ezongeziweyo ze-alloying kunye nekhabhoni, zibonisa ubulukhuni obuphuculweyo, ukuqina, ukumelana nokudinwa, kunye nokumelana nokunxiba.

Izinto ze-alloys zisetyenziswa ngokuqhelekileyo kwiinkqubo zokutshiza ze-CNC.

Ukucwangciswa kwe-CNC kwenza ukuveliswa kwamacandelo e-state-of-art usebenzisa izinto zentsimbi ye-alloy, ebonisa iimpawu eziphezulu zemishini, imilinganiselo echanekileyo kunye neziphumo ezithembekileyo.Iinketho zenkqubo yoMatshini zibandakanya i-3-axis kunye ne-5-axis ye-CNC yokusila yokwandisa ubuninzi bokuvelisa kunye nokuguquguquka.

Isicelo

I-CNC machining yinkqubo ethembekileyo yokuvelisa amacandelo aphezulu kwintsimbi kunye neplastiki.Iqinisekisa iimpawu ezigqwesileyo zoomatshini, imilinganiselo echanekileyo kunye neziphumo ezihambelanayo.Ukongeza, sikwabonelela nge-flexible 3-axis kunye ne-5-axis CNC yokusila ukuhlangabezana neemfuno ezahlukeneyo zokuvelisa.

Iingenelo

Iimpawu eziphezulu zoomatshini bomatshini be-CNC ziqinisekisa ukuqina kunye nomgangatho weendawo ezizivelisayo.Inika ukuchaneka okuchukumisayo kunye nokuphindaphinda, iqinisekisa iziphumo ezichanekileyo nezingaguqukiyo kuyo yonke inkqubo yokuvelisa.

Iingxaki

Xa kuthelekiswa noshicilelo lwe-3D, i-CNC machining ibeka imiqobo engakumbi kubunzima bejometri obufikelelekayo, ekugqibeleni inciphisa uluhlu lwamathuba oyilo akhoyo.

Ixabiso

$$$$$

Ixesha lokukhokhela

< 2 iintsuku

Ukutyeba kweendonga

0.75mm

Ukunyamezelana

±0.125mm (±0.005″)

Ubungakanani benxalenye enkulu

200 x 80 x 100 cm

Yintoni ialloys

I-alloys zizinto zetsimbi ezenziwe ngokudibanisa izinto ezimbini okanye ngaphezulu, kunye nokuba enye yazo ibe yintsimbi.Ukudibaniswa kwezinto ezahlukeneyo kunika iimpawu ezithile kwi-alloy eyahlukileyo kwizinto ezizimeleyo.

Iindidi ze-alloys:

Kukho iintlobo ezininzi ze-alloys ezisekelwe kwizinto eziziquletheyo kunye neempawu zazo.Ezinye iintlobo eziqhelekileyo ziquka:

-Intsimbi:Intsimbi yingxubevange yentsimbi kunye nekhabhoni, kunye nomxholo wekhabhoni ngokuqhelekileyo ukusuka kwi-0.2% ukuya kwi-2.1%.Yaziwa ngokomelela kwayo okuphezulu, ukuqina, kunye nokuguquguquka.Intsimbi inokudityaniswa nezinye izinto ukukhulisa iipropathi ezithile.

- Yenziwe ngentsimbi eshayinayo:Intsimbi engatyiwa yintsimbi yintsimbi, ichromium, kwaye ngamanye amaxesha nezinye izinto ezifana nenickel okanye imolybdenum.Iyakwazi ukumelana ne-corrosion, iyenza ifaneleke kwizicelo apho ukuxhathisa umhlwa kunye ne-staining kufuneka.

-Aluminiyam ialloys:I-alloys ye-aluminiyam yenziwa ngokudibanisa i-aluminiyam kunye nezinye izinto ezifana nobhedu, i-zinc, i-magnesium, okanye i-silicon.Ezi alloys zinika ibhalansi elungileyo yamandla, iipropathi ezikhaphukhaphu, kunye nokumelana nomhlwa.Zisetyenziswa kakhulu kumashishini afana ne-aerospace, izithuthi, kunye nokwakha.

-Iingxubevange zeTitanium:Iialloyi ze-Titanium zenziwe ngokudibanisa i-titanium nezinye izinto ezifana ne-aluminiyam, i-vanadium, okanye isinyithi.Baziwa ngomlinganiselo wabo wokomelela kubunzima obuphezulu, ukumelana nokugqwesa okugqwesileyo, kunye ne-biocompatibility.Iialloyi ze-Titanium ziqhele ukusetyenziswa kwi-aerospace, amayeza, kunye namashishini ekhemikhali.

Iipropati kunye noncedo:

I-alloys idla ngokubonisa iimpawu eziphuculweyo xa kuthelekiswa neentsimbi ezisulungekileyo.Ezi zakhiwo zinokubandakanya ukonyuka kwamandla, ubunzima, ukuxhathisa ukubola, ukumelana nobushushu, kunye nokuhamba kombane.Ii-alloys nazo ziyakwazi ukulungelelaniswa kwizicelo ezithile ngokulungelelanisa ukubunjwa kunye nobuchule bokucubungula.

Usetyenziso:

I-alloys inoluhlu olubanzi lwezicelo kumashishini ahlukeneyo.Umzekelo, intsimbi isetyenziswa kumacandelo okwakha, eemoto, nakwimveliso.Intsimbi engatyiwa ngokuqhelekileyo ifumaneka kwizixhobo zasekhitshini, izixhobo zonyango, kunye nezixhobo zokulungisa imichiza.Iialloys ze-aluminiyam zisetyenziswa kwiinqwelo-moya, kwiimoto, nasekupakisheni.Iialloys ze-Titanium zifumana izicelo kwi-aerospace, implants zonyango, kunye nezixhobo zemidlalo.

Iinkqubo zokuvelisa:

Ii-alloys zinokuveliswa ngeendlela ezahlukeneyo, kubandakanya ukuphosa, ukubumba, ukukhupha, kunye nomgubo wesinyithi.Ukukhethwa kwenkqubo yokuvelisa kuxhomekeke kwi-alloy ethile kunye neempawu ezifunwayo.