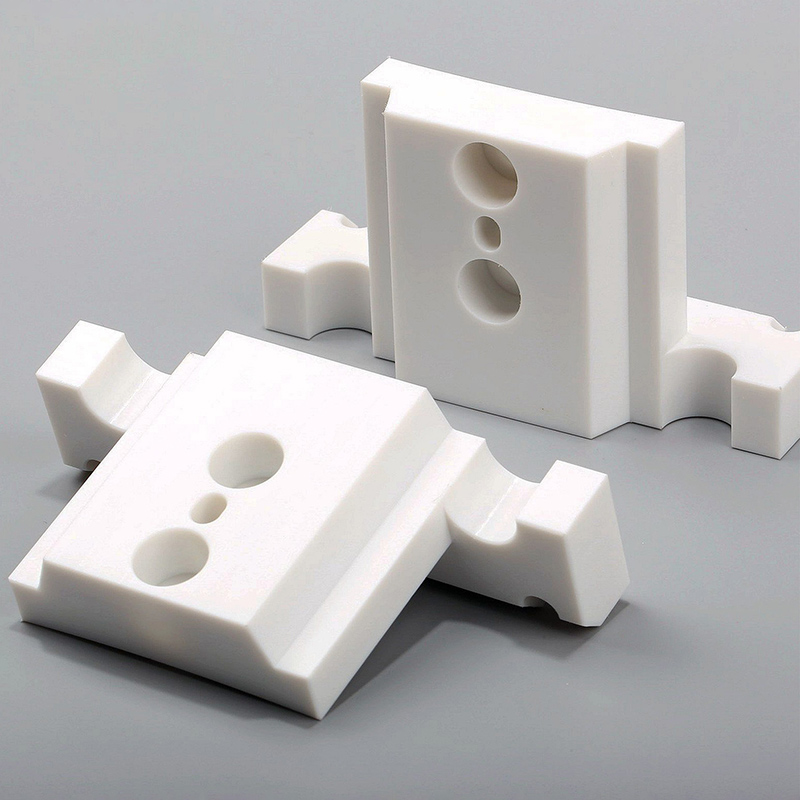

CNC Machining Aluminum Parts Manufacturer in China for Precision Solutions

When it comes to CNC machining aluminum parts, I take great pride in delivering precision and quality. As a trusted manufacturer in China, I understand the importance of reliable components for your projects. My experience ensures that every part is crafted with attention to detail, meeting the highest industry standards. I’m dedicated to providing customized solutions tailored to your specific needs. Whether you need prototypes or large-scale production, I can handle it all. My state-of-the-art equipment and skilled team work together to achieve optimal results, ensuring your satisfaction with each order. I know that choosing the right manufacturer is crucial for your business success, and I'm here to build a lasting relationship. Together, we can enhance your product offerings and meet market demands effectively. Let's collaborate and turn your ideas into high-quality aluminum parts that stand out!

Cnc Machining Aluminum Parts Is The Best in 2025

In 2025, the landscape of CNC machining aluminum parts has evolved significantly, positioning it as the best choice for global buyers seeking precision, durability, and cost-effectiveness. With advancements in technology and manufacturing processes, CNC machining has become increasingly efficient, allowing for the production of complex geometries and tighter tolerances. This means that industries ranging from aerospace to automotive can now leverage high-quality aluminum components that meet stringent specifications while reducing lead times and material waste. Aluminum has established itself as a preferred material due to its lightweight nature, corrosion resistance, and excellent thermal conductivity. As companies strive for sustainability, the recyclability of aluminum enhances its appeal. In addition, the wide array of aluminum alloys available enables engineers to select the best option for their specific applications, ensuring optimal performance and longevity. As global demand for exceptional quality and innovative designs rises, CNC machining processes in 2025 will continue to meet these challenges head-on, providing buyers with tailored solutions that drive their businesses forward. Moreover, the globalization of supply chains means that sourcing CNC machined aluminum parts has never been easier. With enhanced communication technologies and logistics, companies can efficiently connect with manufacturers around the world. This accessibility allows for competitive pricing and exceptional customer service, reinforcing the role of CNC machining in supporting businesses across various sectors. As we look ahead, it’s clear that CNC machining aluminum parts will remain at the forefront of manufacturing capabilities, ready to meet the needs of a dynamic marketplace.

CNC Machining Aluminum Parts Is The Best in 2025

| Part Name | Material | Application | Production Time (Days) | Machining Process |

|---|---|---|---|---|

| Bracket A | Al6061 | Automotive | 10 | Milling |

| Housing B | Al7075 | Aerospace | 15 | Turning |

| Panel C | Al5052 | Electronics | 7 | Drilling |

| Component D | Al2024 | Military | 12 | Waterjet Cutting |

| Fixture E | Al6063 | Manufacturing | 20 | CNC Routing |

Related Products

Cnc Machining Aluminum Parts Industry Giant Your Trusted OEM Partner

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Kachi machining

-

Top