Products

CNC Machining in Aluminum

CNC Machining In Mild Steel

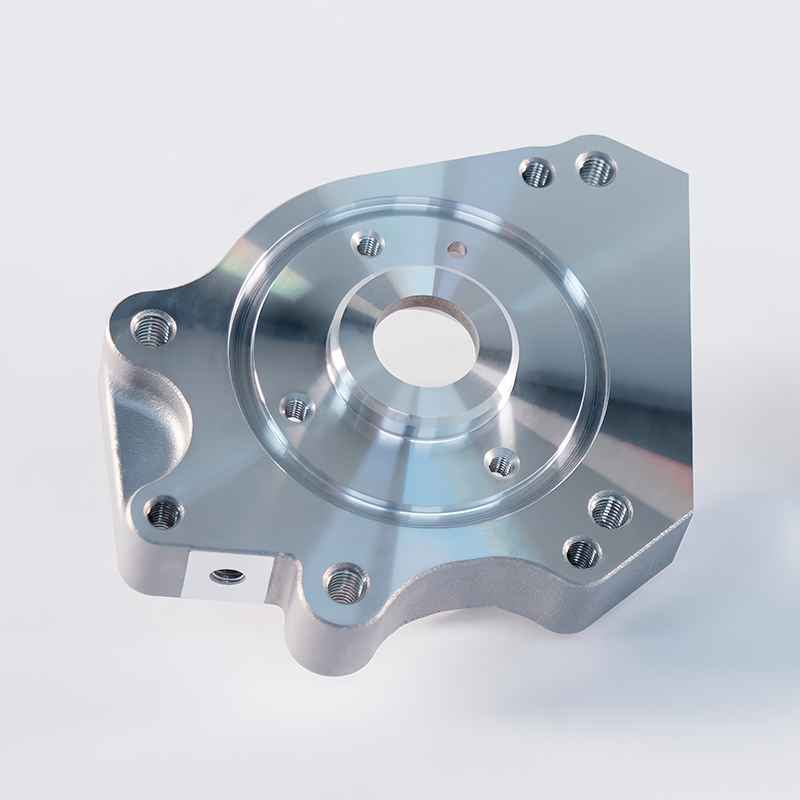

Order CNC machined parts made from mild steel, a low-cost metal alloy with excellent machinability and weldability, as well as high stiffness.

Mild steel can also be carburized to enhance its hardness.

Mild steel materials are commonly used in CNC machining processes.

CNC machining is capable of producing first-class components from mild steel materials, providing excellent mechanical properties, precise dimensions and reliable results. Manufacturing processes can utilize 3-axis or 5-axis CNC milling options to achieve the desired results.

Application

Metal and plastic parts manufactured by CNC machining have excellent mechanical properties, ensuring durability and reliability. Additionally, CNC machining offers exceptional precision in producing the precise dimensions of these components. Moreover, the technology guarantees high repeatability, ensuring consistent and reproducible results. To meet a variety of manufacturing needs, 3-axis and 5-axis CNC milling options are available.

Advantages

CNC machining is known for its superior mechanical properties, which in turn guarantee the quality and durability of the parts produced. Accuracy and repeatability are two key advantages of this manufacturing method, as it ensures precise and consistent results throughout the process.

Disadvantages

Compared to 3D printing, the design possibilities for CNC machining are limited due to stricter restrictions on geometric complexity.

Price

$$$$$

Lead Time

< 10 days

Wall Thickness

0.75mm

Tolerances

±0.125mm (±0.005″)

Max part size

200 x 80 x 100 cm

Mild steel materials

Mild steel, also known as low carbon steel or plain carbon steel, is a type of carbon steel that contains a low amount of carbon (typically less than 0.25%). It is the most common form of steel used in various industries due to its affordability, versatility, and ease of fabrication.

One of the key advantages of mild steel is its excellent weldability. It can be easily welded using various methods, such as arc welding, MIG welding, and TIG welding, making it suitable for joining different components and structures.

Although mild steel has lower strength compared to high-strength steels, it still exhibits sufficient strength for many applications. It also offers good ductility, allowing it to withstand deformation without fracturing. Mild steel can be further strengthened through processes such as cold working or heat treatment.

However, mild steel is susceptible to corrosion, especially in environments with high moisture or exposure to chemicals. To enhance its corrosion resistance, mild steel can be coated with protective coatings such as paint, galvanizing, or powder coating.