Cov khoom

CNC Machining nyob rau hauv Aluminium

CNC Machining hauv Mild Steel

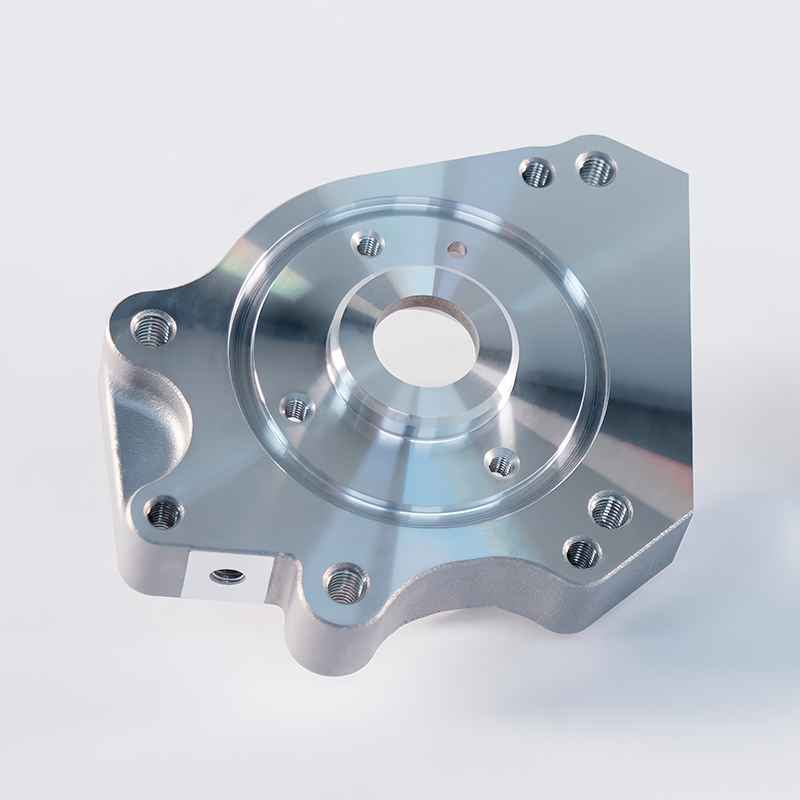

Txiav CNC machined qhov chaw ua los ntawm cov hlau me me, tus nqi qis hlau alloy nrog zoo heev machinability thiab weldability, nrog rau siab nruj.

Cov hlau me me kuj tuaj yeem ua tau carburized los txhim kho nws cov hardness.

Cov ntaub ntawv me me steel feem ntau yog siv hauv CNC machining txheej txheem.

CNC machining muaj peev xwm tsim cov khoom hauv chav kawm thawj zaug los ntawm cov khoom siv hlau me me, muab cov khoom siv kho tshuab zoo, qhov ntev thiab cov txiaj ntsig txhim khu kev qha.Cov txheej txheem tsim khoom tuaj yeem siv 3-axis lossis 5-axis CNC milling kev xaiv kom ua tiav cov txiaj ntsig xav tau.

Daim ntawv thov

Hlau thiab yas qhov chaw tsim los ntawm CNC machining muaj cov cuab yeej zoo heev, ua kom ruaj khov thiab kev ntseeg tau.Tsis tas li ntawd, CNC machining muaj qhov tshwj xeeb tshwj xeeb hauv kev tsim cov qhov ntev ntawm cov khoom no.Ntxiv mus, thev naus laus zis guarantees siab repeatability, kom ntseeg tau tias zoo ib yam thiab reproducible.Txhawm rau ua tau raws li ntau yam kev xav tau, 3-axis thiab 5-axis CNC milling xaiv muaj.

Qhov zoo

CNC machining paub txog nws cov cuab yeej zoo tshaj plaws, uas nyob rau hauv lem lav qhov zoo thiab durability ntawm cov khoom tsim.Qhov tseeb thiab rov ua tau zoo yog ob qho txiaj ntsig tseem ceeb ntawm txoj kev tsim khoom no, vim nws ua kom cov txiaj ntsig zoo thiab zoo ib yam thoob plaws hauv cov txheej txheem.

Qhov tsis zoo

Piv rau 3D luam ntawv, qhov tsim muaj peev xwm rau CNC machining raug txwv vim muaj kev txwv nruj dua ntawm geometric complexity.

Nqe

$$$$$

Lub Sijhawm Lead

<10 hnub

Phab ntsa Thickness

0.75mm ib

Kev kam rau siab

± 0.125 hli (± 0.005 ″)

Max qhov loj me

200 x 80 x 100 cm

Cov khoom siv hlau me me

Cov hlau me, tseem hu ua cov pa roj carbon tsawg lossis cov pa roj carbon steel, yog ib hom carbon steel uas muaj cov pa roj carbon tsawg (feem ntau tsawg dua 0.25%).Nws yog ntau hom steel siv nyob rau hauv ntau yam lag luam vim nws pheej yig, versatility, thiab yooj yim ntawm fabrication.

Ib qho txiaj ntsig tseem ceeb ntawm cov hlau me me yog nws cov weldability zoo heev.Nws tuaj yeem yooj yim welded siv ntau txoj hauv kev, xws li arc vuam, MIG vuam, thiab TIG vuam, ua rau nws tsim nyog rau kev koom nrog cov khoom sib txawv thiab cov qauv.

Txawm hais tias cov hlau me me muaj lub zog qis dua piv rau cov hlau muaj zog, nws tseem muaj zog txaus rau ntau daim ntawv thov.Nws kuj muaj qhov zoo ductility, cia nws tiv taus deformation yam tsis muaj kev tawg.Cov hlau me me tuaj yeem ua kom muaj zog ntxiv los ntawm cov txheej txheem xws li kev ua haujlwm txias lossis kev kho cua sov.

Txawm li cas los xij, cov hlau me me yog qhov cuam tshuam rau corrosion, tshwj xeeb tshaj yog nyob rau hauv ib puag ncig uas muaj dej noo siab lossis raug tshuaj lom neeg.Txhawm rau txhim kho nws cov kev tiv thaiv corrosion, cov hlau me me tuaj yeem raug coated nrog cov txheej txheem tiv thaiv xws li xim, galvanizing, lossis hmoov txheej.