CNC Machining Aluminum Services by Leading China Manufacturer

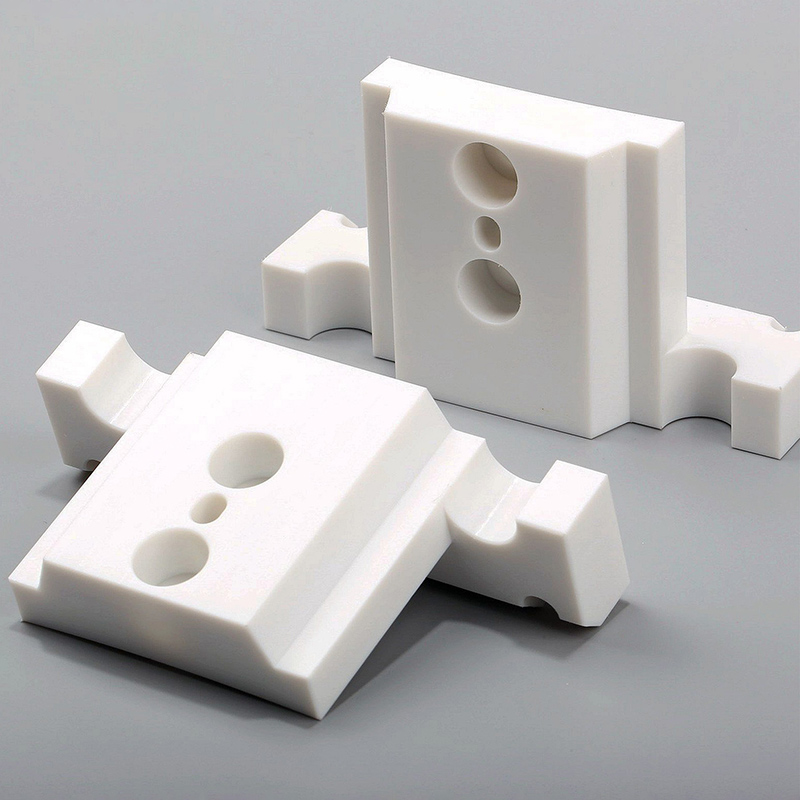

As a leading manufacturer in China specializing in CNC machining aluminum, we understand the unique needs of B2B purchasers. Our precision machining services ensure top-quality components tailored to your specifications. With advanced technology and a skilled team, we produce aluminum parts that meet rigorous standards, optimizing performance for a variety of applications. We take pride in our ability to handle both small and large production runs, delivering consistency and reliability every time. Our commitment to customer satisfaction means we’re here to support you throughout the entire process, from initial design to final delivery. Partnering with us, you'll benefit from competitive pricing without compromising on quality. Let us help you elevate your projects with our expert CNC machining services in aluminum. If you're seeking a dependable manufacturer in China, look no further—together, we can achieve outstanding results that drive your business forward.

Cnc Machining Aluminum Custom Solutions, Where Service Meets Innovation

In today's rapidly evolving manufacturing landscape, the demand for precision and customization has never been higher. CNC machining aluminum offers a flexible and innovative solution for businesses seeking high-quality components tailored to their specific needs. Whether it's intricate designs or large production runs, leveraging cutting-edge CNC technology allows for unparalleled accuracy and efficiency in the manufacturing process. Our commitment to service excellence ensures that each project, no matter how complex, is approached with a client-centric focus. We collaborate closely with our partners to understand their unique requirements, providing expert guidance from design through to production. This synergy not only enhances the quality of the final product but also fosters innovation, as we strive to develop solutions that push the boundaries of traditional machining practices. By choosing our CNC machining solutions, global buyers are not only investing in top-tier manufacturing capabilities but also in a partnership that prioritizes their goals. This blend of service and technology empowers businesses to stay competitive in their respective markets, confidently meeting the ever-increasing demands for precision-engineered aluminum components.

Cnc Machining Aluminum Custom Solutions, Where Service Meets Innovation

| Solution Type | Application | Material | Tolerance | Lead Time |

|---|---|---|---|---|

| Anodizing | Aerospace Components | 6061 Aluminum | ±0.005" | 4 weeks |

| CNC Milling | Automotive Parts | 7075 Aluminum | ±0.001" | 6 weeks |

| Laser Cutting | Medical Devices | 5052 Aluminum | ±0.02" | 3 weeks |

| Bending | Construction Fixtures | 2154 Aluminum | ±0.005" | 5 weeks |

Related Products

Cnc Machining Aluminum Stands Out Where Innovation Meets 2025

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Kachi machining

-

Top