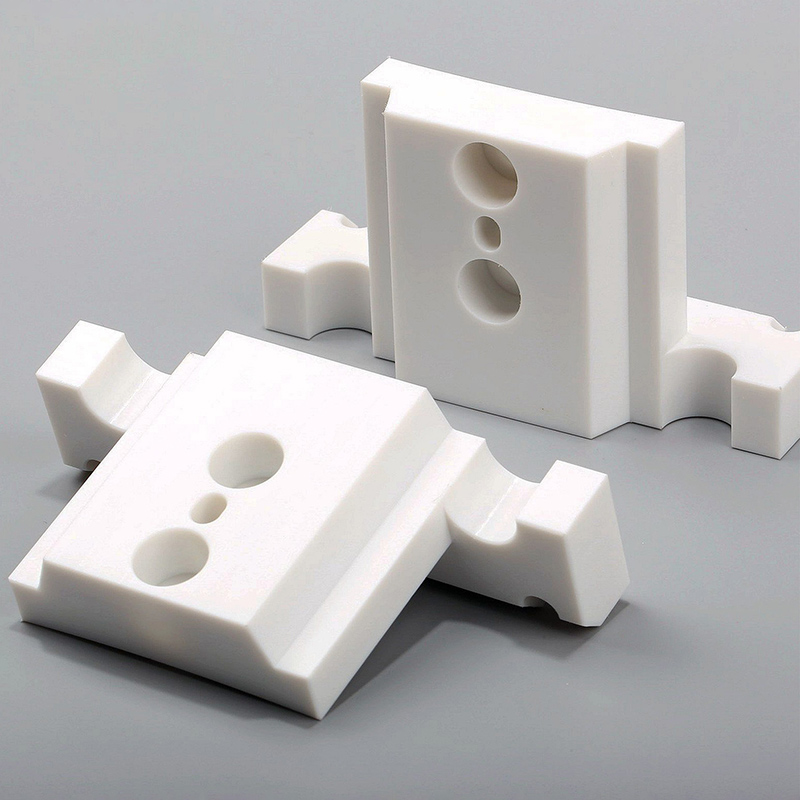

Cnc Aluminum Milling Parts Manufacturer in China - Quality & Precision

As a manufacturer of high-quality CNC aluminum milling parts in China, I understand the importance of precision and durability in every component. Our CNC aluminum milling parts are designed to meet the strictest industry standards, ensuring that they not only fit perfectly but also perform reliably in demanding applications. With advanced machining technology and skilled engineers, we customize each part to suit your specific requirements, whether you need small batches or large production runs. I pride myself on delivering exceptional quality while maintaining competitive pricing. Our commitment to customer satisfaction means that you’ll receive prompt support and timely delivery, making your procurement process smooth and efficient. If you’re looking to source top-notch CNC aluminum milling parts, let’s collaborate to bring your project to life with precision and excellence. Together, we can achieve the results that drive your business forward.

Cnc Aluminum Milling Parts Is The Best Winning in 2025

As we look toward 2025, the demand for precision-engineered components continues to rise, with CNC aluminum milling parts leading the charge. These parts are not just components; they represent the pinnacle of manufacturing innovation, delivering unparalleled accuracy and efficiency that modern industries crave. From aerospace to automotive and electronics, CNC aluminum milling plays a pivotal role in meeting stringent production standards while ensuring lightweight durability. One of the key advantages of CNC aluminum milling components is their versatility. Manufacturers can produce complex geometries and intricate designs that were once deemed impossible with traditional machining methods. This capability not only enhances product performance but also optimizes supply chains by reducing material waste and production times. As global industries prioritize sustainability and efficiency, embracing CNC aluminum milling parts can be a strategic move for procurement professionals seeking reliable suppliers. By investing in advanced CNC aluminum milling technology now, companies will be well-positioned to capitalize on the growing market opportunities in 2025. As the manufacturing landscape continues to evolve, partnering with experts in precision machining can provide a competitive edge, ensuring that they remain at the forefront of innovation and meet their customers' ever-changing demands.

Cnc Aluminum Milling Parts Is The Best Winning in 2025

| Part Name | Material | Dimensions (mm) | Weight (g) | Surface Finish |

|---|---|---|---|---|

| CNC Bracket | Aluminum 6061 | 100 x 50 x 10 | 150 | Anodized |

| CNC Housing | Aluminum 7075 | 150 x 100 x 20 | 300 | Powder Coated |

| CNC Plate | Aluminum 6063 | 200 x 150 x 5 | 80 | Brushed |

| CNC Base | Aluminum 6061 | 250 x 200 x 15 | 400 | Anodized |

Related Products

Cnc Aluminum Milling Parts Factory Custom Solutions,

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Kachi machining

-

Top