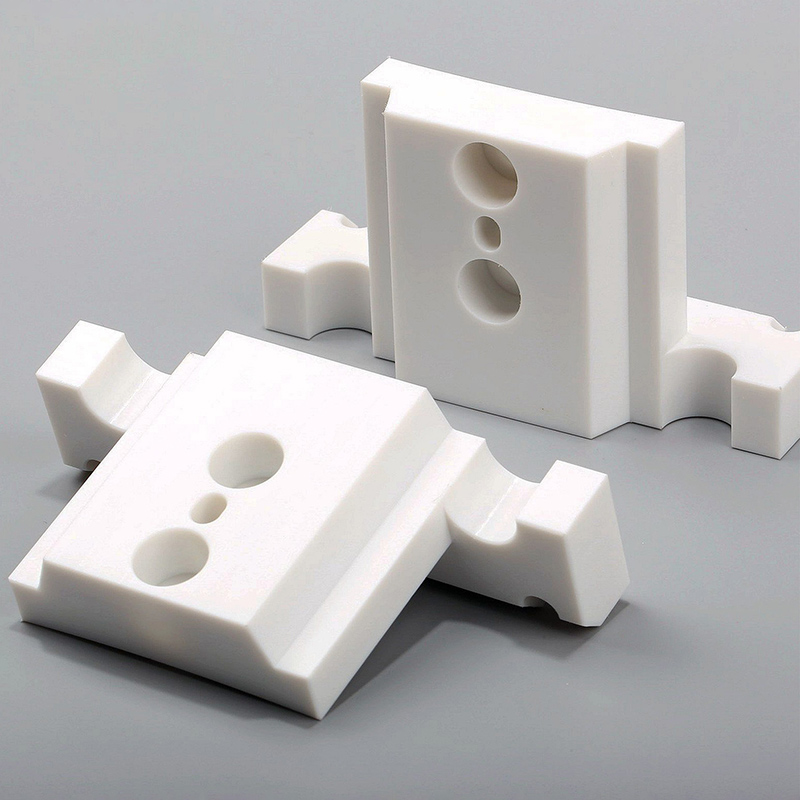

High-Quality Aluminum CNC Turning Parts from China Manufacturer

As a leading manufacturer in China, I pride myself on providing high-quality aluminum CNC turning parts tailored to meet your specific needs. Our precision-engineered components are crafted using advanced CNC machining technology, ensuring exceptional accuracy and durability. Whether you're in the automotive, aerospace, or electronics industry, our parts can enhance your product performance. With robust material selection and stringent quality control, I guarantee that every order meets international standards. You can rely on us for both small and large-scale production, with flexible lead times to keep your project on schedule. I understand the B2B market demands not just quality but reliability and competitive pricing. Let's collaborate to bring your ideas to life with our custom solutions. Get in touch to learn more about how we can support your business with our aluminum CNC turning parts made in China!

Aluminum Cnc Turning Part Service Guarantees Peak Performance

In today's competitive manufacturing landscape, the demand for high-quality aluminum CNC turning parts has surged. These parts are essential for various applications, ranging from automotive to aerospace, where precision and reliability are paramount. By utilizing advanced CNC (Computer Numerical Control) technology, manufacturers can achieve intricate designs, reduce waste, and enhance efficiency. This makes CNC turning an ideal choice for producing aluminum components that meet the stringent quality standards required in global markets. When sourcing aluminum CNC turning parts, it is crucial to partner with a manufacturer that not only understands the complexities of precision machining but also guarantees performance through quality assurance processes. A commitment to excellence ensures that parts are not only manufactured to specifications but are also tested rigorously to withstand the demands of their intended applications. This level of quality assurance minimizes the risk of defects, reduces lead times, and ultimately leads to higher customer satisfaction. Additionally, a reliable service provider understands the importance of customization. No two projects are the same; thus, the ability to adapt design and machining processes to fit unique specifications is essential. Companies that focus on collaborative partnerships with their clients can better align their productions with market needs, ensuring that every component contributes to the overall success of the end product. By prioritizing quality and service, global buyers can confidently invest in CNC turning services that promise peak performance and durability in every turn.

Aluminum CNC Turning Part Service Guarantees Peak Performance

| Part ID | Material | Dimension (mm) | Tolerance | Finishing Type | Weight (kg) |

|---|---|---|---|---|---|

| AP001 | Aluminum 6061 | 50 x 30 x 10 | ±0.05 | Anodized | 0.25 |

| AP002 | Aluminum 7075 | 40 x 20 x 15 | ±0.03 | Polished | 0.2 |

| AP003 | Aluminum 2024 | 60 x 40 x 20 | ±0.04 | Brushed | 0.35 |

| AP004 | Aluminum 5052 | 70 x 30 x 10 | ±0.05 | Anodized | 0.3 |

Related Products

Aluminum Cnc Turning Part Service Where Innovation Meets 2025

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Kachi machining

-

Top