Since the 19th century, cars have become an indispensable presence. The advent of the automobile changed the course of civilization, providing rapid personal transportation for most people, spawning new job opportunities, and ushering in a new pop culture.

The automotive manufacturing industry is currently spread across the globe. At the beginning of the 20th century, the United States was the dominant player in automobile manufacturing. Today, however, cars are mass-produced across the globe. For example, China is currently the largest manufacturer of road vehicles in the world. In 2018 alone, global car sales reached 81.5 million vehicles.

In the century and a half since the first car was invented, the methods used to build cars have evolved tremendously. When mass production of automobiles began, much of the assembly was done by hand, especially during the time Ford was producing the legendary Model T.

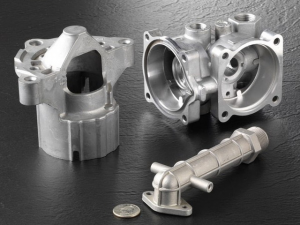

Since the 1960s, however, robots have become more popular. These machines can complete tasks such as welding and assembly in less time than human hands. CNC machining technology, which uses computers and automation to perform activities such as drilling and boring, is currently a viable option for prototyping and production of specific automotive parts. This process involves performing tasks such as drilling and boring. Milling of automotive parts is both common and useful, and many automotive supply chains rely on OEMs (original equipment manufacturers) that provide CNC machining services.

CNC machines take digital files and convert them into computer instructions. These instructions are then sent to power tools such as drills, lathes or milling machines. Blocks of material, called workpieces, are transformed into final products using machine tools, which can provide greater precision than traditionally machined components.

Which automotive parts are produced using CNC machining?

1: Engine block

The engine block is an important component of the engine. CNC processing can ensure the accuracy of its internal space and the smoothness of its surface. CNC machining can ensure the dimensional accuracy of key parts such as the cylinder bore and piston ring groove of the cylinder block, thereby improving the efficiency and stability of the engine.

2: Brake disc

As the core component of the braking system, the manufacturing accuracy of the brake disc is directly related to the driving safety of the car. Using CNC machining can ensure that the flatness and roundness of the brake disc meet higher requirements, and improve the braking performance and wear resistance of the brake disc.

3: Wheel bearings

Wheel bearings are key components that support wheel rotation. CNC processing can improve their accuracy and wear resistance, thereby extending their service life. CNC machining can ensure the dimensional accuracy of the inner hole and outer circle of the bearing, and improve the working stability and safety of the bearing.

4: Steering mechanism

The steering mechanism is directly related to the car’s handling performance, and CNC processing can ensure the accuracy and stability of the steering mechanism. CNC machining can improve the matching accuracy of components of the steering mechanism, thereby improving the vehicle’s handling and safety.

The use of CNC machining technology in the automotive industry has many advantages, including:

High precision: CNC machining can achieve high-precision parts processing, ensuring the accuracy and consistency of auto parts, helping to improve the performance and quality of the entire vehicle.

Production efficiency: CNC processing can realize automated production, improve production efficiency and output, shorten the production cycle, and reduce costs, thereby allowing automobile manufacturers to meet market demand faster.

Flexibility: CNC machining can be quickly adjusted and processed according to different design requirements and specifications, providing automakers with greater flexibility and customization capabilities.

Complex parts processing: CNC processing can process parts with complex shapes and structures, including curves, holes and threads, etc., to meet the diversified and complex manufacturing needs of automotive parts.

Resource saving: CNC processing can minimize the waste of raw materials, improve resource utilization, and is conducive to environmental protection and sustainable development.

Post time: Jan-10-2024