Stainless Steel CNC Machining: Top China Manufacturer for Precision Parts

When it comes to Stainless Steel CNC Machining, I understand the critical role precision and durability play in your projects. As a leading manufacturer in China, I take pride in delivering high-quality machined components tailored to meet your specific needs. My CNC machining services leverage cutting-edge technology and skilled craftsmanship, ensuring that every piece meets rigorous standards. I’m committed to helping you streamline your production process while saving costs without compromising on quality. Whether you need intricate designs or bulk orders, I can handle it all with efficiency. My dedication to timely delivery and exceptional customer support means you can trust that your projects will stay on track. Let's collaborate to bring your vision to life with precision-engineered stainless steel components that stand the test of time. Reach out today, and let’s discuss how my services can benefit your business!

Stainless Steel Cnc Machining Is The Best For the Current Year

Stainless steel CNC machining has emerged as the premier choice for manufacturers and buyers alike in the current year, thanks to its unparalleled precision, durability, and versatility. As businesses worldwide continue to seek advanced solutions to meet their production demands, the ability to create complex shapes and intricate designs with stainless steel has proven invaluable. This machining process not only enhances the strength of components but also boosts resistance to corrosion and heat, making it ideal for a myriad of industries, including automotive, aerospace, and medical equipment. Moreover, advancements in CNC technology have significantly improved efficiency and reduced lead times, allowing for quicker response to market changes. With automated systems, manufacturers can achieve consistent quality while optimizing material usage, which is critical in today’s cost-sensitive environment. Companies investing in stainless steel CNC machining can expect to see not just enhanced product performance but also a competitive edge in their respective markets. As procurement decisions lean towards sustainable and high-quality manufacturing practices, stainless steel CNC machining stands out as the go-to option for forward-thinking businesses globally. In summary, the transition to stainless steel CNC machining is not merely a trend but a strategic move towards innovation and quality. As global procurement continues to evolve, those who harness the capabilities of this advanced machining method will position themselves as leaders in their industries. Embracing this technology can pave the way for new opportunities, ensuring that businesses remain at the forefront of manufacturing excellence.

Stainless Steel Cnc Machining Is The Best For the Current Year

| Category | Advantage | Application | Material Properties | Surface Finish |

|---|---|---|---|---|

| Aerospace | High strength-to-weight ratio | Aircraft components | Corrosion resistance | Polished |

| Automotive | Durability | Engine parts | High tensile strength | Brushed |

| Medical | Biocompatibility | Surgical instruments | Non-reactive | Matte |

| Construction | Longevity | Structural components | High ductility | Electropolished |

| Food Processing | Hygienic | Processing equipment | Non-porous | Pickled |

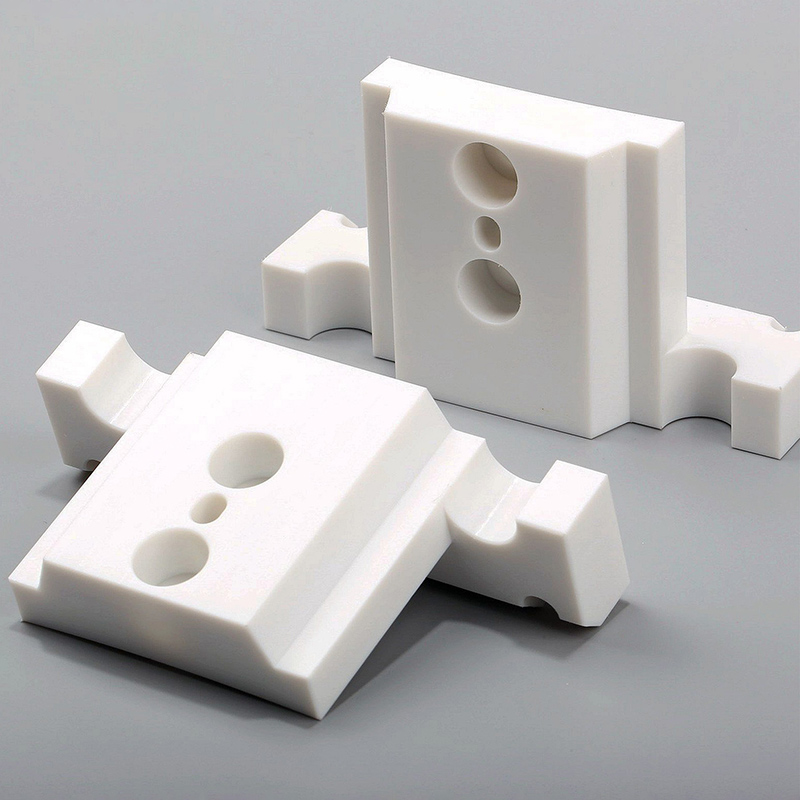

Related Products

Stainless Steel Cnc Machining Leads the Global Market Delivers Unmatched Quality

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Kachi machining

-

Top