China Manufacturer of Aluminum Precision Machining for Optimal Performance

When it comes to Aluminum Precision Machining, I've seen firsthand how vital it is for achieving high-quality, precise components. Our manufacturing capabilities in China allow us to provide exceptional precision and cost-effective solutions that elevate your projects. I personally oversee the processes to ensure that our state-of-the-art equipment meets the rigorous standards expected in today's competitive market. What sets us apart is our commitment to collaboration. Understanding your specific requirements helps us deliver tailored solutions that fit seamlessly within your production line. Whether you’re in automotive, aerospace, or electronics, my team and I are dedicated to producing parts that not only meet but often exceed expectations. Choosing a reliable manufacturer doesn’t have to be daunting. With our expertise in Aluminum Precision Machining, you can trust that you’re getting quality and performance without compromise. Let’s talk about how we can help you achieve your objectives and drive your business forward.

Aluminum Precision Machining Supplier Service Backed by Expertise

In the competitive landscape of precision manufacturing, sourcing high-quality aluminum components is critical for businesses across various industries. As a leading supplier, we prioritize delivering exceptional machining services, utilizing state-of-the-art technology and skilled personnel. Our expertise in aluminum precision machining ensures that we can meet the specific requirements of each project, providing customized solutions that enhance performance and durability. We understand the unique challenges faced by global procurement professionals. Our commitment to quality control and rigorous testing processes guarantees that every component meets international standards. By leveraging advanced machining techniques, we offer greater efficiency and precision in production, allowing our clients to reduce lead times and increase their operational efficiency. Our dedicated team is always available to provide consultation and support, ensuring that our clients receive the best advice and solutions tailored to their needs. Partnering with a reliable supplier not only simplifies the procurement process but also opens up new opportunities for innovation. With our extensive experience in the field, we can assist businesses in navigating complex manufacturing challenges while maintaining a competitive edge. Trust us to deliver not just products, but a partnership built on expertise, reliability, and a shared commitment to excellence.

Aluminum Precision Machining Supplier Service Backed by Expertise

| Service Type | Material Specifications | Machining Techniques | Applications | Lead Time |

|---|---|---|---|---|

| CNC Milling | 6061-T6 Aluminum | 3-Axis and 5-Axis Machining | Aerospace, Automotive Components | 2-4 Weeks |

| CNC Turning | 7075 Aluminum | Automatic and Manual Turning | Medical Devices, Electronics | 3-5 Weeks |

| Sheet Metal Fabrication | 5052 Aluminum | Laser Cutting, Bending, Welding | Housing, Framework | 4-6 Weeks |

| Surface Finishing | ALUMINUM ALLOYS | Anodizing, Powder Coating | Consumer Products, Automotive | 1-3 Weeks |

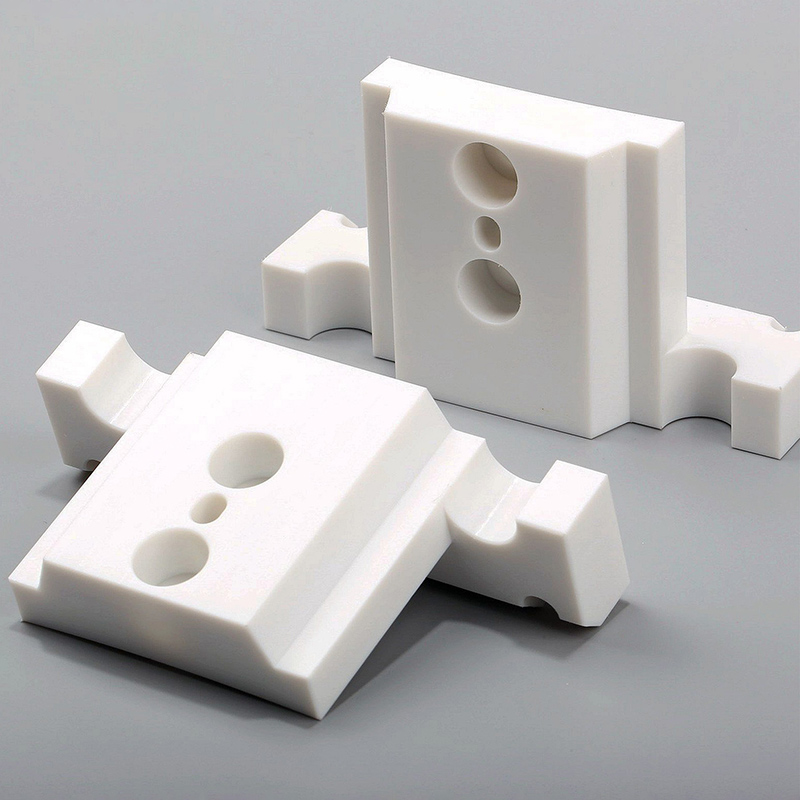

Related Products

Aluminum Precision Machining in 2025 For the Current Year

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Kachi machining

-

Top