Top China Manufacturer of Precision Steel Machining Services

When it comes to steel machining, our expertise in China as a manufacturer truly sets us apart. We provide precision machining services tailored to your specific needs, ensuring that every part meets the highest quality standards. Our advanced machinery and skilled technicians enable us to handle various steel types, delivering custom solutions that enhance your production processes. I understand that every project is unique, and that’s why I work closely with you to ensure your specifications are met with precision. Whether you need small components or large-scale production runs, my commitment to excellence guarantees your satisfaction. By choosing a reliable steel machining partner in China, you're not just sourcing products; you're investing in quality and efficiency for your business. Let’s collaborate to create exceptional steel components that drive your projects forward. Engage with us today, and let’s discuss how we can meet your machining needs!

Steel Machining Manufacturer Dominates

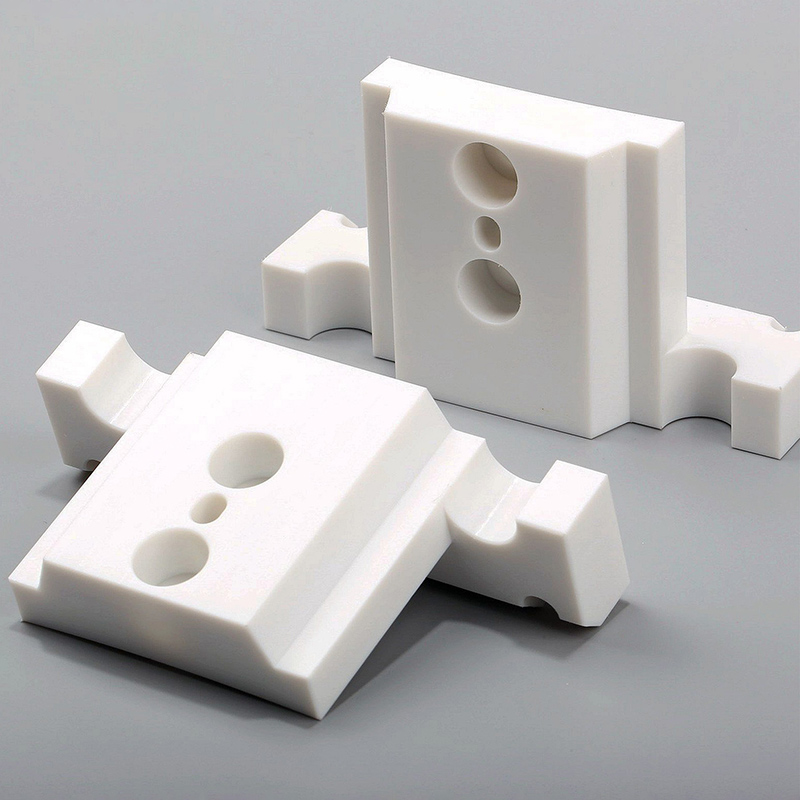

In today's competitive landscape, steel machining manufacturers are playing a pivotal role in various industries, from automotive to aerospace. A standout in this arena is renowned for their state-of-the-art technology and precise engineering processes, enabling them to produce high-quality machined components that meet the stringent demands of global markets. With a focus on precision and reliability, these manufacturers utilize advanced machining techniques and equipment to ensure that every product meets exact specifications, ultimately enhancing the efficiency and performance of end applications. What sets leading steel machining entities apart is their commitment to innovation and quality control. By adopting cutting-edge technologies such as CNC machining and automation, they are not only able to increase production capabilities but also reduce lead times significantly. This positions them as ideal partners for businesses looking to optimize their supply chains. Additionally, these manufacturers understand the importance of customizing solutions to meet specific client requirements, making them a go-to choice for procurement professionals around the world. As global demand for high-quality machined steel parts continues to rise, the industry is witnessing a shift towards sustainable practices and materials. Many manufacturers are now integrating eco-friendly processes that minimize waste and energy consumption, reflecting a commitment to both quality and environmental responsibility. This forward-thinking approach not only appeals to environmentally conscious buyers but also strengthens the manufacturer’s position in a rapidly evolving marketplace. For procurement specialists, partnering with a leading steel machining manufacturer means accessing high-performance solutions that enhance product longevity and overall operational efficiency.

Steel Machining Manufacturer Dominates

| Dimension (mm) | Weight (kg) | Machining Speed (m/min) | Material Type | Tolerance (mm) |

|---|---|---|---|---|

| 100 x 50 x 20 | 5.5 | 150 | Steel Alloy | ±0.1 |

| 120 x 60 x 30 | 7.3 | 140 | Carbon Steel | ±0.2 |

| 150 x 75 x 50 | 10.2 | 130 | Stainless Steel | ±0.15 |

| 200 x 100 x 40 | 12.7 | 125 | Alloy Steel | ±0.2 |

Related Products

Steel Machining Winning in 2025 Where Service Meets Innovation

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Kachi machining

-

Top