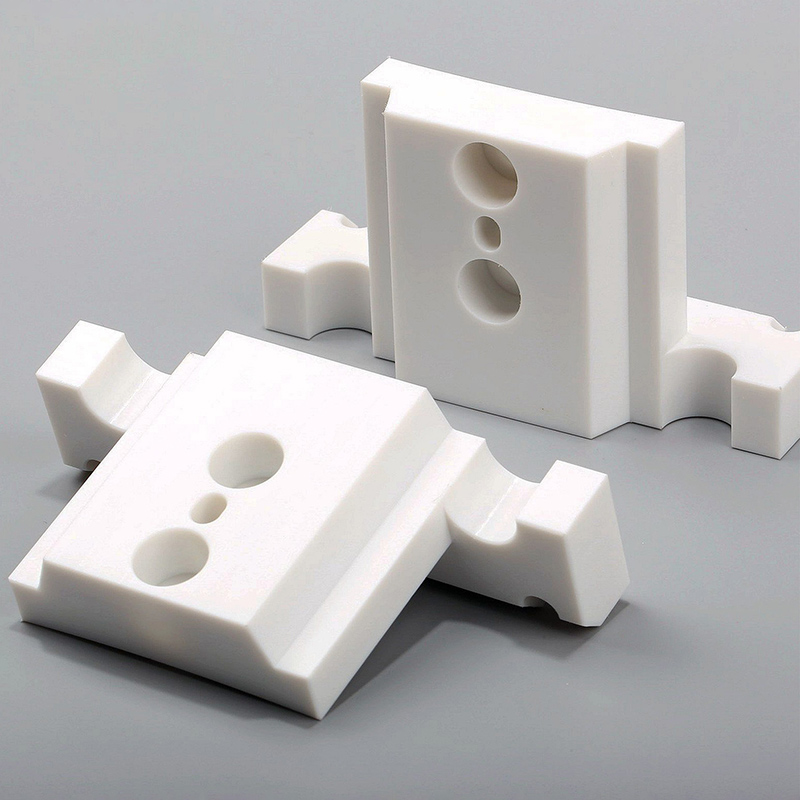

CNC Steel Parts Manufacturer in China: High-Quality Precision Solutions

When it comes to sourcing high-quality CNC steel parts, I can confidently say that partnering with a reliable manufacturer in China has been a game-changer for my business. The precision and durability I’ve experienced from these CNC parts are unmatched. They cater to a wide range of applications, ensuring that my projects are not just completed on time but also exceed industry standards. Navigating the manufacturing process was made seamless with open communication and expert guidance from the Chinese manufacturers I work with. They understand the specific requirements that my business needs, allowing for customized solutions that fit perfectly. The balance of cost-effectiveness and superior quality has transformed my supply chain efficiency, making it easier to meet increased demand. If you are in need of CNC steel parts that deliver both quality and reliability, connecting with manufacturers in China just makes sense. Let's elevate your production capabilities together.

Cnc Steel Parts Stands Out in 2025

In 2025, the CNC steel parts industry is poised for remarkable advancements, driven by innovations in manufacturing technologies and an ever-increasing demand for precision-engineered components across various sectors. As global procurement strategies evolve, companies are looking for suppliers who can not only deliver high-quality products but also adapt quickly to changing industry needs. CNC (Computer Numerical Control) machining stands out as a key solution due to its ability to produce intricate designs with exceptional accuracy and consistency. The rise of automation and smart manufacturing processes is transforming the landscape of CNC steel parts production. Suppliers that embrace cutting-edge technologies such as AI-driven analytics and advanced robotics will enhance their operational efficiencies and quality control measures. This ensures that procurement specialists can rely on their suppliers for timely deliveries of components that meet strict specifications, ultimately reducing time-to-market for finished products. Moreover, sustainability is becoming a vital consideration in procurement decisions. The CNC steel parts sector is making strides in implementing eco-friendly practices, from sourcing recycled materials to optimizing energy consumption during production. By aligning with suppliers committed to sustainable practices, global buyers not only fulfill their environmental responsibilities but also strengthen their brand reputation in an increasingly eco-conscious market. In this dynamic landscape, the ability to provide innovative, high-quality, and sustainable CNC steel parts will be the defining factor for suppliers aiming to thrive in 2025.

Cnc Steel Parts Stands Out in 2025

| Part Type | Material | Dimension (mm) | Weight (kg) | Finish |

|---|---|---|---|---|

| Bracket | Steel | 200 x 100 x 50 | 1.5 | Galvanized |

| Gear | Carbon Steel | 150 x 150 x 30 | 0.8 | Black Oxide |

| Bracket | Stainless Steel | 250 x 120 x 60 | 2.0 | Polished |

| Rivet | Alloy Steel | 10 x 10 x 50 | 0.1 | Zinc Plated |

| Pin | Tool Steel | 25 x 25 x 100 | 0.4 | Nitride |

Related Products

Cnc Steel Parts For the Current Year Service Backed by Expertise

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Kachi machining

-

Top