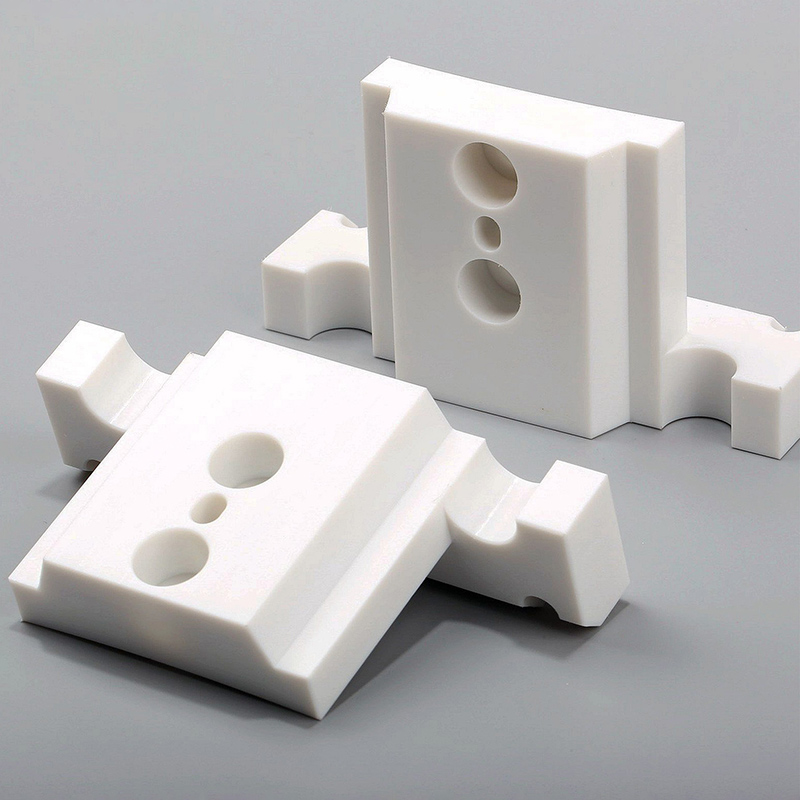

Cnc Aluminum Parts Manufacturer in China: Precision Engineering Solutions

As a seasoned manufacturer of CNC aluminum parts in China, I take pride in delivering high-quality components tailored to meet industry standards. Our parts are crafted using advanced CNC machining technology, ensuring precision and durability for various applications. Whether you’re in aerospace, automotive, or electronics, my CNC aluminum parts are designed to fit your specific needs. I understand that sourcing reliable components can be challenging. That's why I prioritize clear communication and timely delivery to help streamline your production process. With competitive pricing and a commitment to quality, I strive to be your trusted partner in manufacturing. Let me assist you in optimizing your project with our custom CNC aluminum solutions. I’m here to help you navigate the options, ensuring you get exactly what you need, when you need it. Feel free to reach out anytime to discuss how my products can support your business goals.

Cnc Aluminum Parts Products Outperforms the Competition

In the competitive landscape of CNC aluminum parts manufacturing, quality and precision are paramount. The latest advancements in machining technology and the use of high-grade aluminum alloys have positioned top manufacturers to meet the evolving needs of diverse industries. By leveraging state-of-the-art equipment and a skilled workforce, companies are able to deliver aluminum parts with exceptional dimensional accuracy, surface finish, and durability. This not only satisfies the technical requirements of customers but also helps in enhancing the performance of the final products. Moreover, the ability to customize CNC aluminum components enables manufacturers to cater to specific demands across various sectors, such as automotive, electronics, and aerospace. This flexibility in production allows for faster turnaround times and reduced lead times, giving clients a competitive edge in their respective markets. By focusing on continuous improvement and adopting innovative practices, leading manufacturers are exceeding customer expectations and outperforming their competition. The commitment to sustainability in production processes also plays a crucial role in differentiating top CNC aluminum parts suppliers. Sustainable practices not only reduce environmental impact but can also lead to cost savings, which are passed on to clients. As businesses increasingly prioritize eco-friendly solutions, partnering with manufacturers that prioritize sustainability ensures a strategic alignment with market demands and values. Investing in CNC aluminum parts from industry leaders guarantees reliability and performance, setting a solid foundation for long-term business success.

Cnc Aluminum Parts Products Outperforms the Competition

| Product ID | Material Type | Dimension (mm) | Weight (g) | Processing Time (days) | Surface Finish |

|---|---|---|---|---|---|

| 001 | Aluminum Alloy 6061 | 100 x 50 x 10 | 50 | 5 | Anodized |

| 002 | Aluminum Alloy 7075 | 150 x 75 x 5 | 40 | 7 | Brushed |

| 003 | Aluminum Alloy 5052 | 120 x 60 x 8 | 35 | 6 | Polished |

| 004 | Aluminum Alloy 2024 | 130 x 65 x 12 | 55 | 8 | Powder Coated |

Related Products

Cnc Aluminum Parts Application Factory

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Kachi machining

-

Top