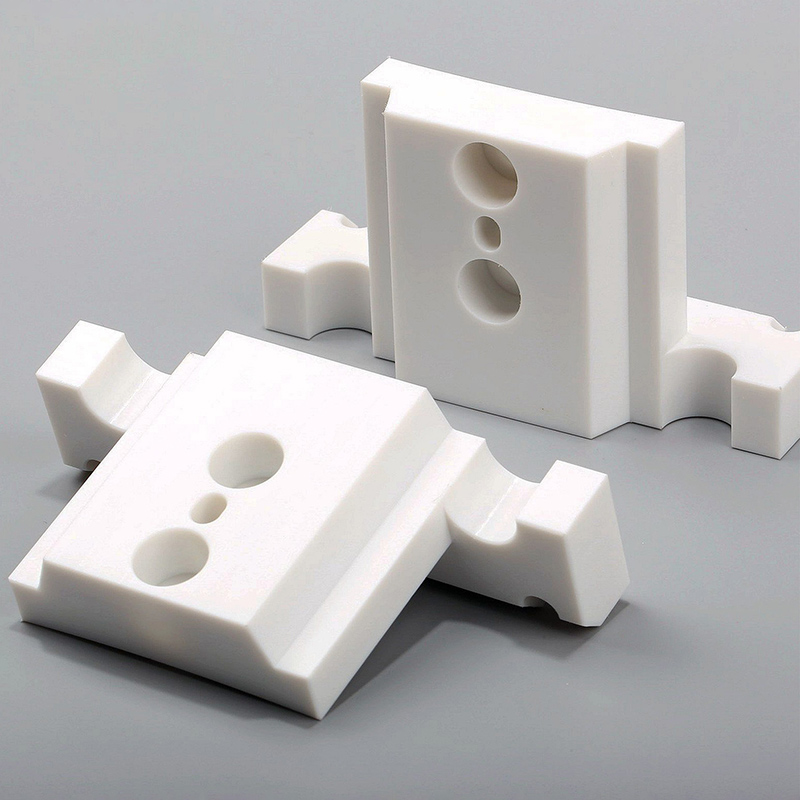

Top China Manufacturer of Aluminum CNC Machining Parts for Your Needs

When searching for high-quality aluminum CNC machining parts, I understand the importance of reliable manufacturing. As a leading manufacturer in China, we specialize in producing precision components tailored to your specific needs. Our state-of-the-art CNC machining technology ensures that each part meets rigorous quality standards, providing you with durability and performance you can count on. I take pride in offering customizable solutions, whether you need a small batch or large-scale production. Our team is dedicated to ensuring timely deliveries, so you can keep your projects on track. By choosing us, you’re not just getting parts; you’re partnering with a manufacturer that values excellence and customer satisfaction. Let us help you streamline your supply chain with superior aluminum CNC machining parts that enhance your products. Together, we can achieve your production goals with efficiency and precision.

Aluminum Cnc Machining Parts Is The Best Pioneers in the Field

In today's competitive manufacturing landscape, aluminum CNC machining parts have emerged as the gold standard for precision and reliability. As industries worldwide continue to innovate, the demand for high-quality components that meet stringent specifications is ever-increasing. CNC machining provides the unparalleled advantage of producing complex geometries while maintaining tight tolerances, making it an essential process for sectors ranging from aerospace to automotive. The lightweight nature of aluminum combined with its excellent strength-to-weight ratio make it an ideal material for a variety of applications. Moreover, its resistance to corrosion and ability to be easily machined allows manufacturers to create intricate designs without compromising on durability. Companies can benefit from shorter lead times and reduced material waste, thus enhancing overall efficiency. By harnessing advanced CNC technology, manufacturers can deliver superior products tailored to the unique needs of their clients, setting them apart in a saturated market. Investing in aluminum CNC machining parts is not just about acquiring components; it's about partnering with pioneers in the field who prioritize quality and precision. Collaborating with experienced manufacturers ensures that clients receive reliable solutions that elevate their projects and drive operational success. In an era where customization and efficiency are vital, aluminum CNC machining is undoubtedly a winning choice for global procurement.

Aluminum CNC Machining Parts Is The Best Pioneers in the Field

| Part Name | Material Type | Dimensional Tolerance | Surface Finish | Application Area |

|---|---|---|---|---|

| Bracket | Aluminum 6061 | ±0.01 mm | Anodized | Automotive |

| Gear Housing | Aluminum 7075 | ±0.02 mm | Powder Coated | Aerospace |

| Connector | Aluminum 6063 | ±0.05 mm | Brushed | Electronics |

| Mounting Plate | Aluminum 2024 | ±0.03 mm | Anodized | Industrial |

| Custom Bracket | Aluminum 5052 | ±0.01 mm | Clear Anodized | Consumer Products |

Related Products

Aluminum Cnc Machining Parts Trusted by Pros Now Trending

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Kachi machining

-

Top