Custom CNC Aluminum Parts Manufacturer in China - Precision Engineering Solutions

When I first started sourcing custom CNC aluminum parts, I realized the importance of finding a reliable manufacturer in China. The quality and precision offered by Chinese manufacturers are truly impressive. My experience with custom CNC aluminum fabrication has shown that we can get tailored solutions that meet specific needs, whether for prototyping or large-scale production. The attention to detail, coupled with competitive pricing, makes China an ideal choice for many businesses. I’ve seen firsthand how working closely with a skilled manufacturer allows for quick turnaround times and adaptability to changes in design. It’s essential to choose a partner who understands the intricacies of your project and can bring visions to life efficiently. If you’re in search of high-quality custom CNC aluminum products, collaborating with a trusted manufacturer can be a game-changer for your business. Let’s take the next step together to achieve your manufacturing goals!

Custom Cnc Aluminum Manufacturers You Can Rely On Custom Solutions,

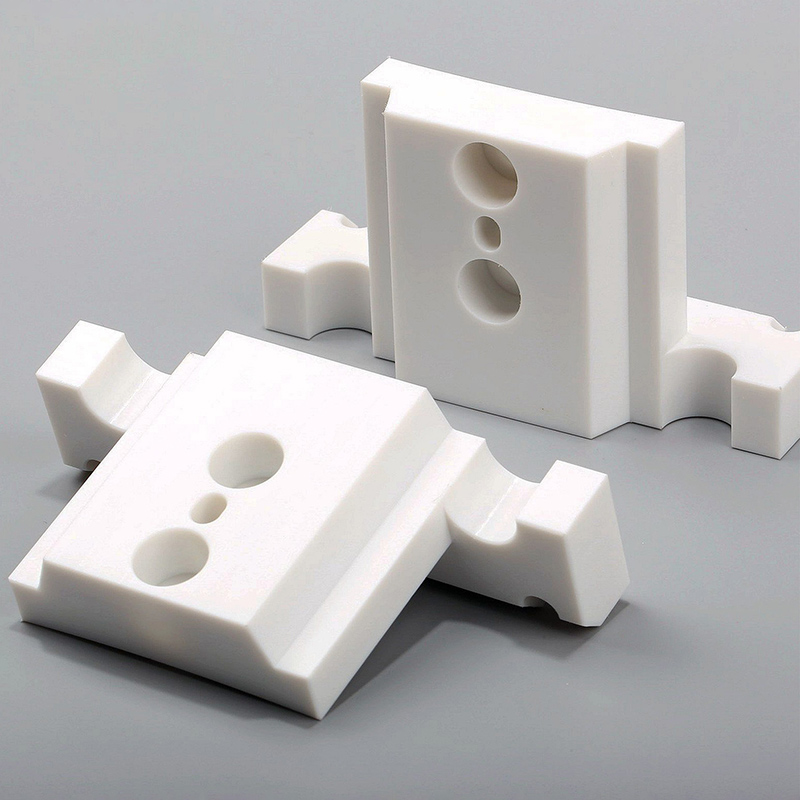

In today’s competitive manufacturing landscape, finding reliable custom CNC aluminum manufacturers is essential for businesses seeking high-quality solutions tailored to their specific needs. When it comes to sourcing precision aluminum components, companies must prioritize manufacturers that boast not only advanced technology but also a commitment to quality and customer service. By partnering with manufacturers known for excellence, businesses can ensure that their unique specifications are met consistently. The right manufacturer offers a wealth of customization options, enabling clients to get exactly what they need for their projects, whether it involves intricate designs or large-scale production runs. Advanced machining techniques and quality control processes guarantee that every piece meets stringent requirements, reducing the risk of defects and ensuring seamless integration into larger systems. Moreover, strong communication throughout the production process fosters trust and helps to effectively resolve any issues that may arise. By choosing dependable custom CNC aluminum manufacturers, global buyers can benefit from improved efficiency and cost-effectiveness. This collaboration not only accelerates production timelines but also supports innovation, allowing businesses to stay competitive in their respective markets. It’s crucial to conduct thorough research and engage with manufacturers that exhibit proven experience in delivering high-quality custom solutions that align perfectly with your operational goals.

Custom CNC Aluminum Manufacturers You Can Rely On Custom Solutions

| Manufacturer | Location | Specialization | Capabilities | Lead Time |

|---|---|---|---|---|

| Manufacturer A | California, USA | CNC Milling and Turning | 5-axis machining, prototyping | 2-3 weeks |

| Manufacturer B | Ontario, Canada | CNC Aluminum Extrusions | Custom extrusion shapes, assembly | 3-4 weeks |

| Manufacturer C | Bavaria, Germany | CNC Laser Cutting | High precision cutting, engraving | 1-2 weeks |

| Manufacturer D | Shenzhen, China | CNC Machining Services | Rapid prototyping, large batch production | 3-5 weeks |

| Manufacturer E | Tokyo, Japan | CNC Precision Parts | Detailed craftsmanship, small tolerances | 2-4 weeks |

Related Products

Custom Cnc Aluminum Service Market Leader

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Kachi machining

-

Top