CNC Processing Stainless Steel by Leading Manufacturers in China

When it comes to CNC processing stainless steel, I understand the importance of precision and quality in every component. As a leading manufacturer in China, we specialize in custom solutions tailored to meet your specific needs. My team and I take pride in utilizing advanced CNC technology and skilled craftsmanship to deliver exceptional results. Every piece we create is designed with your requirements in mind, ensuring durability and effectiveness in any application. Whether you’re in automotive, aerospace, or industrial sectors, I can guarantee our stainless steel products will meet the highest industry standards while optimizing your production efficiency. Choosing us means you’re not just getting a product; you’re partnering with a team that's committed to your success. Let’s transform your ideas into reality with our expert CNC processing services. Your satisfaction is what drives us, and I’m here to make sure you receive nothing less than the best.

Cnc Processing Stainless Steel Leads the Global Market Your Trusted OEM Partner

In the dynamic world of manufacturing, precision and quality stand as cornerstones for success. The rise of CNC processing for stainless steel has positioned this technology at the forefront of the global market. As businesses seek reliable partners capable of delivering top-tier machining solutions, those specializing in stainless steel CNC processing are proving to be essential players. This method not only ensures high accuracy but also enhances the durability and performance of the final products, making it an ideal choice for various industries, from automotive to aerospace. A trusted OEM partner in the CNC processing domain brings not only technical expertise but also a commitment to understanding client needs. By leveraging advanced machinery and skilled professionals, these partners can offer customized solutions that align perfectly with specific project requirements. This adaptability is crucial in today’s fast-paced market, where unique challenges demand tailored approaches. Additionally, with a strong focus on sustainable practices and material efficiency, businesses in the CNC sector are helping clients achieve their environmental goals while maximizing productivity. Investing in a capable CNC processing partner provides global buyers with a competitive edge. Not only does it mean access to superior manufacturing capabilities, but it also translates to shorter lead times and improved supply chain reliability. As the market continues to evolve, those who align with industry-leading partners in stainless steel CNC processing will find themselves better equipped to navigate challenges and seize opportunities, ultimately driving innovation and growth in their respective sectors.

CNC Processing Stainless Steel Leads the Global Market Your Trusted OEM Partner

| Material | Process Type | Application | Dimensional Tolerance (mm) | Lead Time (Weeks) |

|---|---|---|---|---|

| Stainless Steel 304 | CNC Machining | Automotive Parts | ±0.05 | 4 |

| Stainless Steel 316 | Laser Cutting | Marine Equipment | ±0.1 | 3 |

| Stainless Steel 17-4PH | CNC Milling | Aerospace Components | ±0.03 | 6 |

| Stainless Steel 440C | Precision Grinding | Cutting Tools | ±0.02 | 5 |

| Duplex Stainless Steel | Water Jet Cutting | Oil & Gas Applications | ±0.2 | 7 |

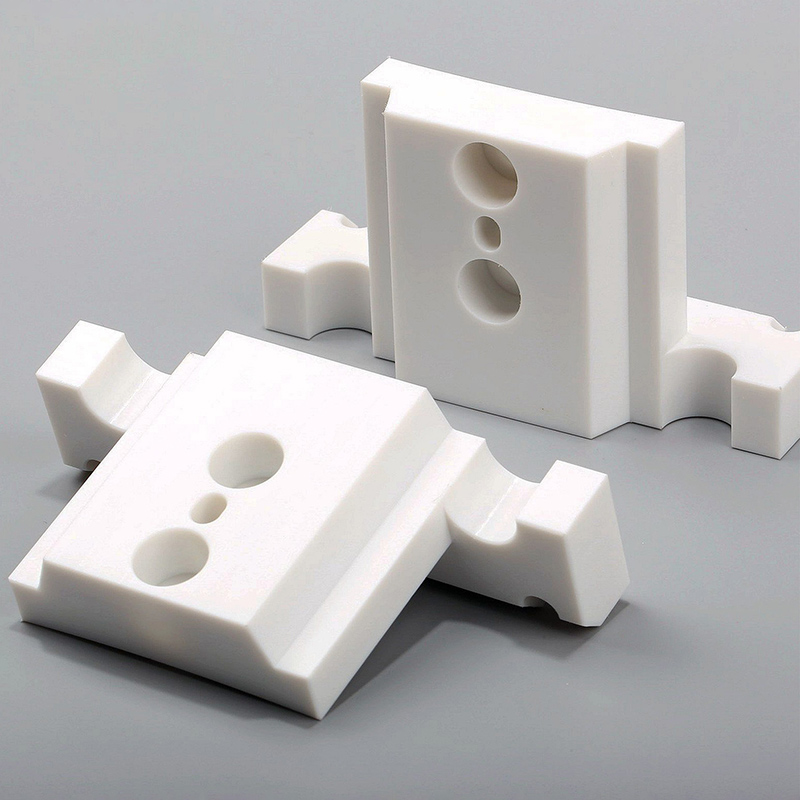

Related Products

Cnc Processing Stainless Steel For the Current Year More Than a Supplier - A Partner

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Kachi machining

-

Top