Top China Manufacturer of Aluminum CNC Machining Services

As a leader in Aluminum CNC machining, we take pride in delivering precision-engineered solutions right from our state-of-the-art facilities in China. Our team of skilled manufacturers is dedicated to providing high-quality products tailored to your specific needs. Whether you need intricate parts for aerospace, automotive, or electronics, we can help bring your designs to life with utmost accuracy. We understand the importance of reliability and cost-effectiveness in your purchasing decisions. That’s why we prioritize efficiency and quality control throughout the entire manufacturing process. With our advanced CNC machinery and experienced engineers, you can trust us to handle everything from prototyping to large-scale production runs. Partnering with us means gaining access to superior craftsmanship and timely deliveries. Let’s work together to turn your ideas into reality while ensuring your competitive edge in the market. Reach out today to explore how we can support your projects with our Aluminum CNC machining expertise.

Aluminum Cnc Machining Now Trending Exceeds Industry Benchmarks

Aluminum CNC machining has emerged as a frontrunner in modern manufacturing, surpassing traditional industry benchmarks and establishing itself as a preferred choice for global procurement. The versatility of aluminum, combined with the precision capabilities of CNC machining, offers manufacturers a unique advantage in producing lightweight, robust, and intricately designed components suitable for various applications including aerospace, automotive, and consumer electronics. The demand for high-quality aluminum components has surged as industries prioritize efficiency, sustainability, and cost-effectiveness. CNC machines not only enhance accuracy but also streamline production processes, reducing time to market. As companies look for reliable partners in their supply chain, the ability to produce complex geometries and maintain tight tolerances has become crucial. Investing in advanced CNC technology allows manufacturers to meet the evolving needs of clients while exceeding compliance standards, making them ideal players in the global market. In this fast-paced environment, companies that embrace innovation in aluminum CNC machining can position themselves as leaders in their industries. By leveraging cutting-edge technology and expertise, they can provide solutions that are not only economically advantageous but also environmentally sustainable. As demand continues to grow, buyers worldwide should seek collaborators that demonstrate a commitment to quality and precision, ensuring that their projects are executed to perfection.

Aluminum CNC Machining Now Trending Exceeds Industry Benchmarks

| Parameter | Industry Benchmark | Current Trend | Improvement (%) |

|---|---|---|---|

| Machining Speed (mm/min) | 1500 | 1800 | 20% |

| Surface Finish (Ra µm) | 1.6 | 0.8 | 50% |

| Tool Life (Hours) | 50 | 65 | 30% |

| Material Waste (%) | 10% | 5% | 50% |

| Setup Time (Hours) | 3 | 2 | 33.33% |

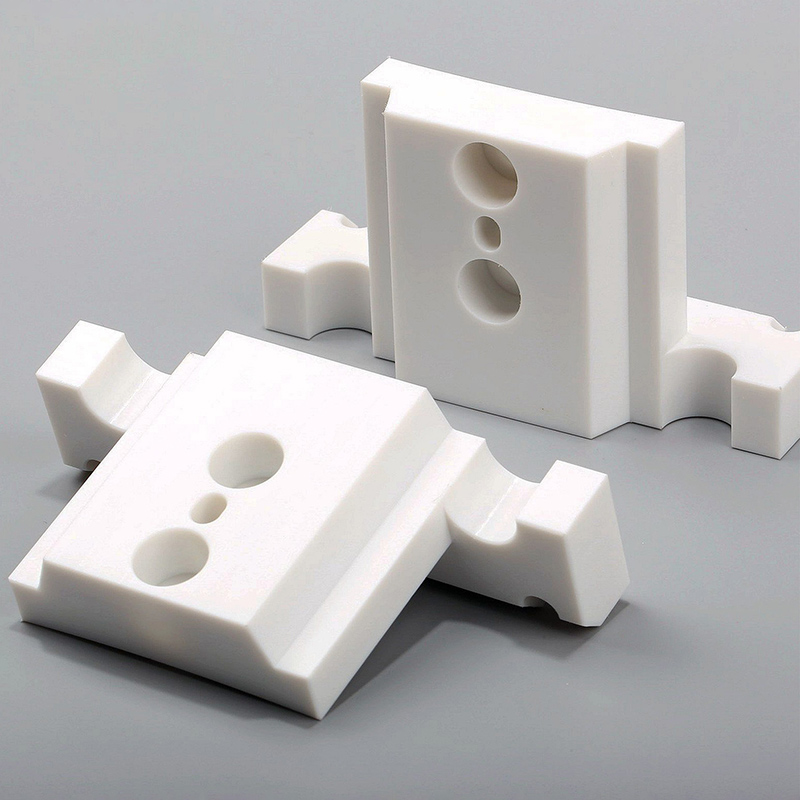

Related Products

Aluminum Cnc Machining Manufacturer Pioneers in the Field

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Kachi machining

-

Top