Imikhiqizo

CNC Machining in Aluminium

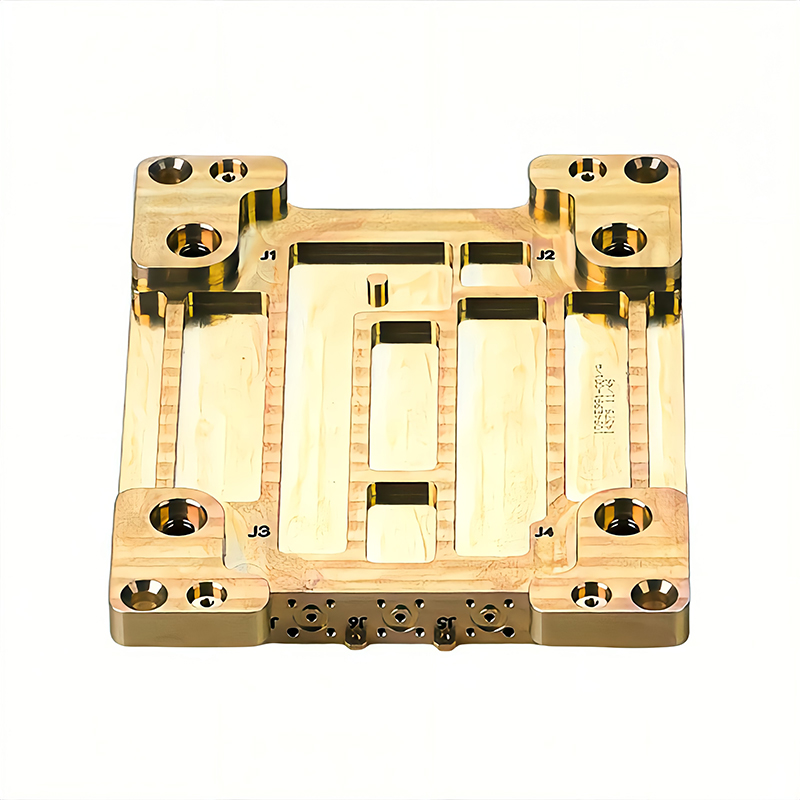

CNC Machining in Copper

I-Copper inokushintshwa okuhle kakhulu kwe-thermal kanye nogesi, okuyenza ilungele izintambo zikagesi, amabhodi esekethe aphrintiwe, nezishintshisi zokushisa.Futhi i-ductile kakhulu futhi ithambile, ivumela ukubunjwa nokubunjwa kalula.Ama-alloys ethusi anokumelana nokugqwala okuhle kanye nezindawo zokulwa namagciwane, okuwenza afanelekele ukusetshenziswa kwezokwelapha nokudla.

Izinto zethusi zivame ukusetshenziswa kuzinqubo zemishini ye-CNC.

I-CNC machining iyindlela yokukhiqiza yokukhiqiza izingxenye ezinezakhiwo ezihlukile zemishini, kanye nokunemba okuphezulu nokuphindaphinda.Le nqubo ingasetshenziswa kokubili izinto zensimbi nezepulasitiki.Ngaphezu kwalokho, ukugaya kwe-CNC kungenziwa kusetshenziswa imishini ye-axis engu-3 noma engu-5, ehlinzeka ngokuguquguquka nokuguquguquka ekukhiqizeni izingxenye eziphezulu zekhwalithi.

Isicelo

I-CNC machining ivame ukusetshenziselwa ukukhiqiza izingxenye zekhwalithi ephezulu ezenziwe ngensimbi nepulasitiki, enikeza izakhiwo ezivelele zemishini, ukunemba, nokungaguquguquki.Iyakwazi kokubili ukugaya i-3-eksisi kanye ne-5-eksisi.

Amandla

I-CNC machining igqama ngezakhiwo zayo ezihlukile zemishini, iletha izingxenye ezinamandla aphakeme nokuqina.Ukwengeza, inikeza ukunemba okuphezulu nokuphindaphinda, iqinisekisa imiphumela engaguquki.

Ubuthakathaka

Uma kuqhathaniswa nokuphrinta kwe-3D, ukwenza imishini ye-CNC kunemikhawulo eyengeziwe ngokuya ngobunkimbinkimbi bejometri engakhiqizwa.

Inani

$$$$$

Isikhathi esiholayo

< 10 izinsuku

Ukubekezelelana

±0.125mm (±0.005″)

Ubukhulu bengxenye yosayizi

200 x 80 x 100 cm

Ukuze CNC Mill yethusi, ungakwazi ukulandela lezi zinyathelo:

Lungiselela amafayela akho e-CAD:Dala noma thola imodeli ye-3D yengxenye yethusi oyifunayo kusofthiwe ye-CAD, futhi uyigcine kufomethi yefayela ehambisanayo (njenge-. STL).

Khetha amathuluzi okusika afanelekile:Khetha amathuluzi okusika afanelekile wokugaya ithusi.Izigayo zokugcina ze-Carbide zivame ukusetshenziselwa umshini wethusi ngenxa yokuqina kwazo okuphezulu nokumelana nokushisa.

Setha umshini we-CNC:Faka amathuluzi okusika akhethiwe futhi uvikele i-workpiece yethusi etafuleni lomsebenzi womshini we-CNC.Qinisekisa ukuqondanisa okufanele kanye nokubopha ukuvimbela noma yikuphi ukunyakaza ngesikhathi sokugaya.

Hlela umshini we-CNC:Sebenzisa isofthiwe ye-CAM ukuze ukhiqize izindlela zamathuluzi nemiyalo yomshini we-CNC.Cacisa isivinini sokusika, ama-feed, kanye nokujula kokugaya ithusi.

Qalisa inqubo yokugaya ye-CNC:Qala umshini we-CNC futhi uwuvumele wenze imiyalelo ehleliwe.Amathuluzi okusika azosusa izinto ezibonakalayo ku-workpiece yethusi ngokusho kwezindlela zamathuluzi ezicacisiwe, kancane kancane azilolonge zibe yifomu elifunayo.

Ukuqeda kanye nokucubungula ngemuva:Uma inqubo yokugaya isiqediwe, susa ingxenye yethusi emshinini we-CNC.Yenza noma yiziphi izinyathelo ezidingekayo zangemuva kokucubungula, ezifana nokukhipha imali noma ukupholisha, ukuze ufinyelele isiphetho osifunayo.

Ngokulandela lezi zinyathelo, ungakwazi ukugaya ithusi nge-CNC futhi udale izingxenye ezinembile neziyinkimbinkimbi ngokusho komklamo wakho.

Izindleko ze-CNC machining copper zingahluka kuye ngezinto ezinjengobunzima nobukhulu bengxenye, uhlobo lwethusi, kanye nenani lezingxenye ezidingekayo.Lezi zinguquko zithinta isikhathi somshini esidingekayo kanye nezindleko zezinto ezingavuthiwe.Ukuze uthole isilinganiso esinembile sezindleko, ungalayisha amafayela akho e-CAD endaweni yesikhulumi futhi usebenzise umakhi wekhwothi ukuze uthole ikhotheshini eyenziwe ngokwezifiso.Lesi sisho sizocubungula imininingwane ethile yephrojekthi yakho futhi sikunikeze izindleko ezilinganisiwe ze-CNC yokwenza izingxenye zakho zethusi.