Zogulitsa

CNC Machining mu Aluminium

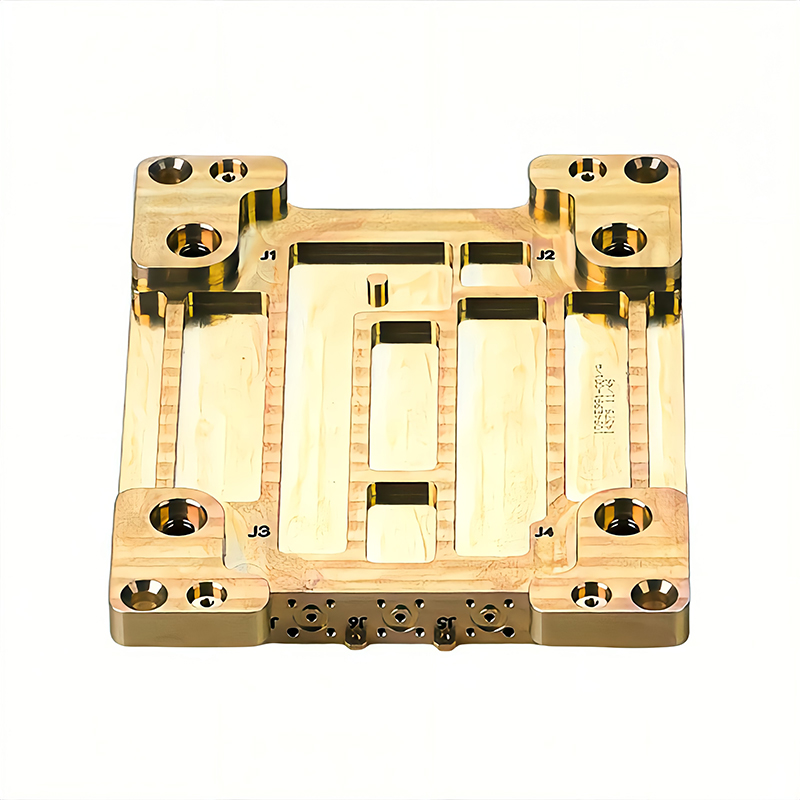

CNC Machining mu Copper

Copper imakhala ndi matenthedwe abwino kwambiri amafuta ndi magetsi, zomwe zimapangitsa kuti ikhale yabwino pama waya amagetsi, ma board osindikizira, ndi zosinthira kutentha.Ndiwopangika kwambiri komanso wosasunthika, wololeza kupangidwa kosavuta komanso kupanga.Ma aloyi amkuwa ali ndi kukana kwa dzimbiri komanso antimicrobial, kuwapangitsa kukhala oyenera kugwiritsa ntchito zamankhwala ndi kukonza chakudya.

Zida zamkuwa zimagwiritsidwa ntchito popanga makina a CNC.

CNC Machining ndi njira yopangira zida zopangira zida zapadera zamakina, komanso kulondola kwambiri komanso kubwerezabwereza.Njirayi ingagwiritsidwe ntchito pazitsulo zonse zachitsulo ndi pulasitiki.Komanso, CNC mphero akhoza kuchitidwa ntchito 3-olamulira kapena 5-olamulira makina, kupereka kusinthasintha ndi kusinthasintha popanga mbali apamwamba.

Kugwiritsa ntchito

Makina a CNC amagwiritsidwa ntchito popanga zida zapamwamba kwambiri zopangidwa ndi zitsulo ndi pulasitiki, zomwe zimapatsa makina apamwamba kwambiri, kulondola, komanso kusasinthika.Imatha kugaya 3-axis ndi 5-axis.

Mphamvu

Makina a CNC amadziwika chifukwa cha mawonekedwe ake apadera amakina, operekera magawo omwe ali ndi mphamvu zapamwamba komanso zolimba.Kuphatikiza apo, imapereka kulondola kwakukulu komanso kubwerezabwereza, kuwonetsetsa zotsatira zosasinthika.

Zofooka

Poyerekeza ndi kusindikiza kwa 3D, makina a CNC ali ndi malire ochulukirapo potengera zovuta za ma geometries omwe amatha kupangidwa.

Mtengo

$$$$$

Nthawi yotsogolera

<10 masiku

Kulekerera

± 0.125mm (± 0.005″)

Kukula kwa gawo lalikulu

200 x 80 x 100 masentimita

Kuti CNC mphero mkuwa, mukhoza kutsatira izi:

Konzani mafayilo anu a CAD:Pangani kapena pezani mtundu wa 3D wa gawo lanu lamkuwa lomwe mukufuna mu pulogalamu ya CAD, ndikusunga mu fayilo yogwirizana (monga . STL).

Sankhani zida zoyenera zodulira:Sankhani zida zoyenera zodulira mphero yamkuwa.Makina omaliza a Carbide amagwiritsidwa ntchito ngati makina amkuwa chifukwa cha kuuma kwawo komanso kukana kutentha.

Konzani makina a CNC:Ikani zida zodulira zosankhidwa ndikuteteza chogwirira ntchito chamkuwa patebulo la makina a CNC.Onetsetsani mayanidwe oyenera ndi clamping kuteteza kusuntha kulikonse pa mphero.

Kupanga makina a CNC:Gwiritsani ntchito pulogalamu ya CAM kuti mupange zida ndi malangizo a makina a CNC.Tchulani kuthamanga, ma feed, ndi kuya kwa mphero yamkuwa.

Yambitsani ndondomeko ya CNC mphero:Yambitsani makina a CNC ndikuwalola kuti achite malangizo okonzedwa.Zida zodulira zidzachotsa zinthu kuchokera kuzitsulo zamkuwa molingana ndi njira zomwe zafotokozedwazo, pang'onopang'ono kuzipanga mu mawonekedwe omwe mukufuna.

Kumaliza ndi post-processing:Mukamaliza mphero, chotsani gawo lamkuwa pamakina a CNC.Chitani njira zilizonse zofunika pambuyo pokonza, monga kubweza kapena kupukuta, kuti mukwaniritse zomwe mukufuna.

Potsatira izi, mutha CNC mphero yamkuwa ndikupanga magawo olondola komanso ovuta malinga ndi kapangidwe kanu.

Mtengo wa CNC Machining mkuwa akhoza zosiyanasiyana malinga ndi zinthu monga zovuta ndi kukula kwa gawo, mtundu wa mkuwa, ndi kuchuluka kwa zigawo zofunika.Zosinthazi zimakhudza nthawi ya makina ofunikira komanso mtengo wazinthu zopangira.Kuti mupeze kuyerekeza kwamitengo yolondola, mutha kukweza mafayilo anu a CAD papulatifomu yathu ndikugwiritsa ntchito omanga ma quote kuti mulandire mtengo wokhazikika.Mawu awa aganizira zatsatanetsatane wa polojekiti yanu ndikukupatsani mtengo woyerekeza wa CNC kukonza magawo anu amkuwa.