Kayayyaki

CNC Machining a Aluminum

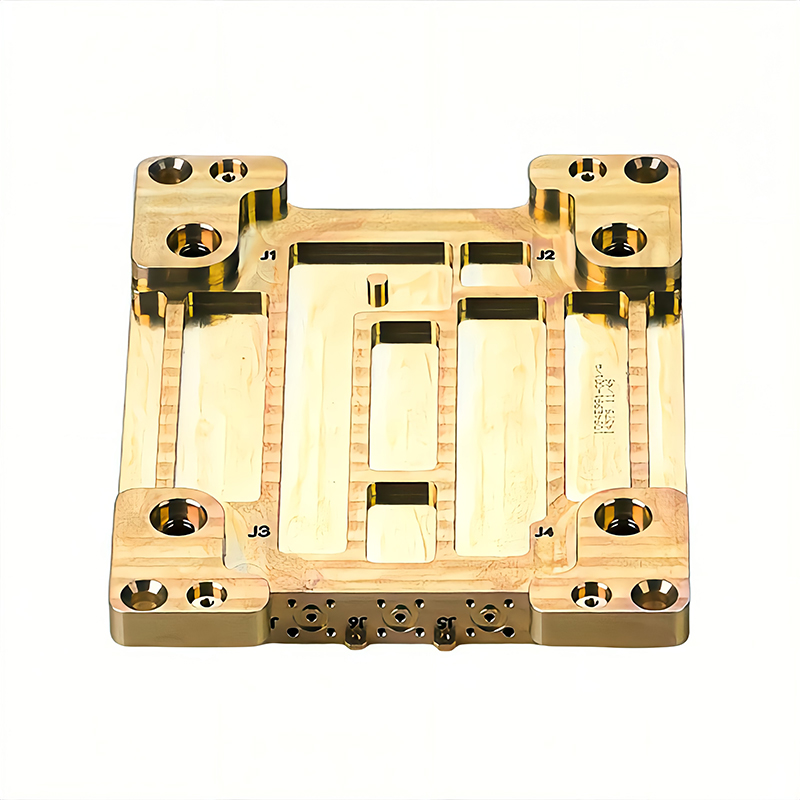

CNC Machining a cikin Copper

Copper yana da kyakkyawan yanayin zafi da wutar lantarki, yana mai da shi manufa don haɗa wutar lantarki, allunan kewayawa, da masu musayar zafi.Har ila yau, yana da matuƙar ductile da malleable, yana ba da damar yin sauƙi da sauƙi.Copper Alloys suna da kyakkyawan juriya na lalata da kaddarorin antimicrobial, suna sa su dace da aikace-aikacen likita da sarrafa abinci.

Ana amfani da kayan jan ƙarfe da yawa a cikin ayyukan injinan CNC.

CNC machining hanya ce ta masana'anta don samar da sassa tare da kaddarorin injiniyoyi na musamman, kazalika da madaidaicin daidaito da maimaitawa.Ana iya amfani da wannan tsari zuwa duka kayan ƙarfe da filastik.Bugu da kari, CNC milling za a iya yi ta amfani da 3-axis ko 5-axis inji, samar da sassauci da kuma versatility a samar da high quality sassa.

Aikace-aikace

CNC machining ana amfani da shi don samar da ingantattun sassa da aka yi da ƙarfe da filastik, suna ba da fitattun kaddarorin inji, daidaito, da daidaito.Yana da ikon duka biyu 3-axis da 5-axis milling.

Ƙarfi

CNC machining ya fito waje don ƙayyadaddun kayan aikin injin sa, yana isar da sassa tare da ingantacciyar ƙarfi da dorewa.Bugu da ƙari, yana ba da daidaito mai girma da maimaitawa, yana tabbatar da daidaiton sakamako.

Rauni

Idan aka kwatanta da bugu na 3D, mashin ɗin CNC yana da ƙarin iyakancewa dangane da ƙayyadaddun abubuwan geometries waɗanda za a iya samarwa.

Farashin

$$$$$

Lokacin Jagora

<kwanaki 10

Haƙuri

± 0.125mm (± 0.005″)

Matsakaicin girman sashi

200 x 80 x 100 cm

To CNC niƙa jan karfe, za ka iya bi wadannan matakai:

Shirya fayilolin CAD naku:Ƙirƙiri ko samo samfurin 3D na ɓangaren jan ƙarfe da kuke so a cikin software na CAD, kuma ku ajiye shi a cikin tsarin fayil mai jituwa (kamar . STL).

Zaɓi kayan aikin yankan da suka dace:Zaɓi kayan aikin yankan da suka dace don niƙa jan ƙarfe.Ana amfani da injina na ƙarshe na Carbide don yin aikin jan karfe saboda tsananin taurinsu da juriya na zafi.

Saita injin CNC:Shigar da zaɓaɓɓun kayan aikin yankan kuma amintaccen aikin aikin jan karfe akan teburin aikin injin CNC.Tabbatar da daidaita daidai da manne don hana kowane motsi yayin aikin niƙa.

Shirya injin CNC:Yi amfani da software na CAM don samar da hanyoyin kayan aiki da umarni don injin CNC.Ƙayyade saurin yankan, ciyarwa, da zurfin don niƙa jan ƙarfe.

Gudanar da tsarin niƙa CNC:Fara na'urar CNC kuma bari ta aiwatar da umarnin da aka tsara.Kayan aikin yankan za su cire kayan daga aikin aikin jan karfe bisa ga ƙayyadaddun hanyoyin kayan aiki, a hankali a tsara shi cikin sigar da ake so.

Kammalawa da aiwatarwa:Da zarar aikin niƙa ya cika, cire ɓangaren jan ƙarfe daga injin CNC.Yi kowane matakan da suka dace bayan aiwatarwa, kamar lalata ko goge goge, don cimma iyakar da ake so.

Ta bin waɗannan matakan, za ku iya CNC niƙa jan ƙarfe kuma ƙirƙirar daidaitattun sassa masu rikitarwa bisa ga ƙirar ku.

Farashin CNC machining jan karfe na iya bambanta dangane da abubuwa kamar rikitarwa da girman sashin, nau'in jan karfe, da adadin sassan da ake buƙata.Waɗannan sauye-sauye suna shafar lokacin injin da ake buƙata da farashin albarkatun ƙasa.Don samun madaidaicin ƙimar farashi, zaku iya loda fayilolin CAD ɗinku akan dandalinmu kuma kuyi amfani da maginin ƙima don karɓar ƙima na musamman.Wannan ƙididdiga za ta yi la'akari da ƙayyadaddun cikakkun bayanai na aikin ku da kuma samar muku da ƙimar da aka kiyasta na CNC machining sassan jan karfe.