Cov khoom

CNC Machining nyob rau hauv Aluminium

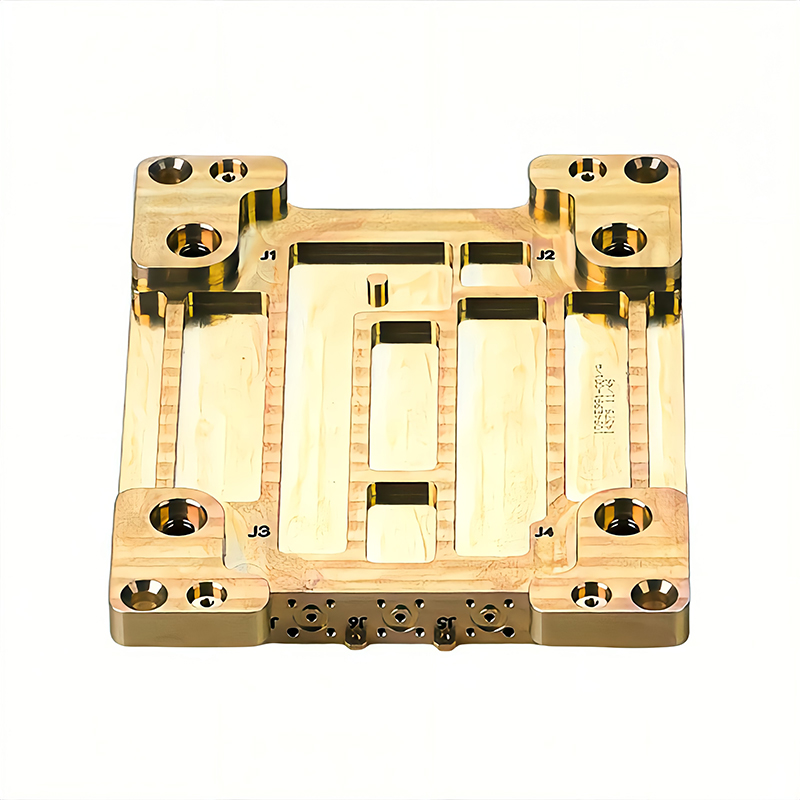

CNC Machining hauv tooj liab

Copper muaj cov thermal conductivity thiab hluav taws xob zoo heev, ua rau nws zoo tagnrho rau kev siv hluav taws xob, cov ntawv luam tawm, thiab cov khoom siv hluav taws xob.Nws kuj yog ductile heev thiab malleable, tso cai rau yooj yim shaping thiab sib sau.Copper alloys muaj zoo corrosion kuj thiab antimicrobial zog, ua rau lawv haum rau kev kho mob thiab zaub mov ua daim ntaub ntawv.

Cov khoom siv tooj liab feem ntau yog siv hauv CNC machining txheej txheem.

CNC machining yog ib txoj hauv kev tsim khoom tsim khoom nrog cov khoom siv tshwj xeeb, nrog rau kev ua haujlwm siab thiab rov ua dua.Cov txheej txheem no tuaj yeem siv rau cov khoom siv hlau thiab yas.Tsis tas li ntawd, CNC milling tuaj yeem ua tau siv 3-axis lossis 5-axis tshuab, muab kev yooj yim thiab ntau yam hauv kev tsim cov khoom zoo.

Daim ntawv thov

CNC machining feem ntau yog siv los tsim cov khoom zoo ua los ntawm cov hlau thiab yas, muab cov khoom siv zoo, precision, thiab sib xws.Nws muaj peev xwm ntawm 3-axis thiab 5-axis milling.

Lub zog

CNC machining stands rau nws cov khoom tshwj xeeb txhua yam, xa cov khoom nrog superior zog thiab durability.Tsis tas li ntawd, nws muaj qhov raug siab thiab rov ua dua, ua kom cov txiaj ntsig zoo ib yam.

Tsis muaj zog

Piv rau 3D luam ntawv, CNC machining muaj ntau qhov kev txwv nyob rau hauv cov nqe lus ntawm cov complexity ntawm geometries uas yuav ua tau.

Nqe

$$$$$

Lub Sijhawm Lead

<10 hnub

Kev kam rau siab

± 0.125 hli (± 0.005 ″)

Max qhov loj me

200 x 80 x 100 cm

Rau CNC zeb tooj liab, koj tuaj yeem ua raws li cov kauj ruam no:

Npaj koj cov ntaub ntawv CAD:Tsim lossis tau txais tus qauv 3D ntawm koj qhov xav tau tooj liab hauv CAD software, thiab khaws cia rau hauv cov ntaub ntawv sib xws (xws li . STL).

Xaiv cov cuab yeej txiav tsim nyog:Xaiv cov cuab yeej txiav tsim nyog rau milling tooj liab.Carbide kawg mills feem ntau siv rau tooj liab machining vim lawv siab hardness thiab kub tsis kam.

Teeb lub tshuab CNC:Txhim kho cov cuab yeej txiav uas tau xaiv thiab ruaj ntseg tooj liab workpiece mus rau CNC tshuab lub rooj ua haujlwm.Xyuas kom muaj kev sib raug zoo thiab clamping kom tsis txhob muaj kev txav thaum lub sijhawm milling.

Program ntawm CNC tshuab:Siv CAM software los tsim cov cuab yeej thiab cov lus qhia rau lub tshuab CNC.Qhia qhov txiav ceev, pub, thiab qhov tob rau milling tooj liab.

Khiav cov txheej txheem CNC milling:Pib lub tshuab CNC thiab cia nws ua raws li cov lus qhia programmed.Cov cuab yeej txiav yuav tshem tawm cov khoom siv los ntawm tooj liab workpiece raws li cov txheej txheem toolpaths, maj mam shaping nws mus rau hauv daim ntawv xav tau.

Kev ua tiav thiab tom qab ua tiav:Thaum cov txheej txheem milling tiav, tshem cov tooj liab ntawm lub tshuab CNC.Ua txhua yam tsim nyog tom qab ua cov kauj ruam, xws li deburring lossis polishing, kom ua tiav qhov kev xav tau saum npoo.

Los ntawm kev ua raws li cov kauj ruam no, koj tuaj yeem CNC zeb tooj liab thiab tsim qhov tseeb thiab sib txawv raws li koj tus qauv tsim.

Tus nqi ntawm CNC machining tooj liab tuaj yeem sib txawv nyob ntawm seb yam xws li qhov nyuaj thiab qhov loj ntawm qhov, hom tooj liab, thiab qhov ntau ntawm qhov xav tau.Cov kev hloov pauv no cuam tshuam rau lub sijhawm tshuab xav tau thiab tus nqi ntawm cov khoom siv raw.Txhawm rau kom tau txais tus nqi kwv yees kom raug, koj tuaj yeem xa koj cov ntaub ntawv CAD mus rau peb lub platform thiab siv tus tsim cov ntawv sau kom tau txais cov lus hais.Qhov kev tsocai no yuav txiav txim siab txog cov ntsiab lus tshwj xeeb ntawm koj qhov project thiab muab koj cov nqi kwv yees ntawm CNC machining koj qhov tooj liab.