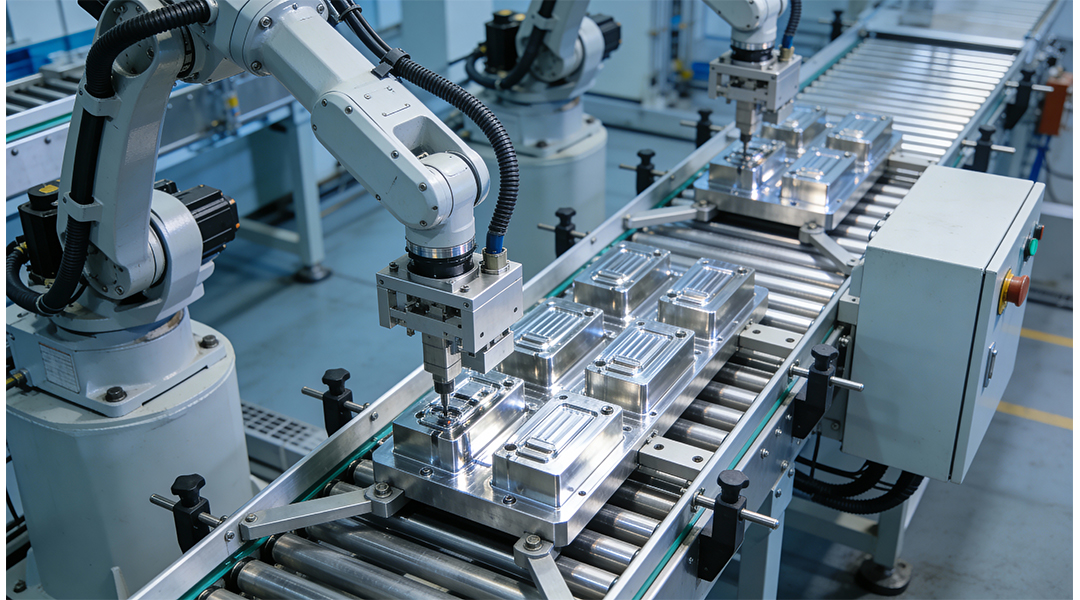

Choosing the right material is one of the most critical decisions when manufacturing CNC parts for automation equipment. Material selection not only affects durability and precision, but also impacts machining efficiency, surface quality, corrosion resistance, and overall lifecycle cost.

Among numerous available materials, Aluminum 6061, Aluminum 6082, Stainless Steel 304, and Stainless Steel 316 are four of the most commonly used materials for CNC machining in automation systems. This guide compares their properties, strengths, weaknesses, and best-use scenarios—helping engineers and buyers make smarter material decisions.

Why Material Selection Matters in CNC Machining for Automation

Precision & Tolerance Stability

Materials with different hardness, stiffness, and thermal expansion behave differently under cutting forces. Poor material choice can cause:

- Dimensional drift

- Poor flatness

- Surface chatter

- Out-of-tolerance issues

Automation components—such as robotic joints, precision brackets, sensors housings—require dimensional stability, making material selection crucial.

Production Efficiency & Machining Time

Material machinability directly affects:

- Cutting speed

- Tool wear

- Setup requirements

- Cooling demand

- Surface roughness

Better machinability = lower manufacturing cost + faster CNC cycle time.

Durability & Lifecycle Performance

Automation equipment often operates continuously. Materials must withstand:

- Fatigue

- Corrosion

- Impact

- Environmental exposure

- Cleaning chemicals

Different materials perform differently in each environment.

Aluminum Alloys for CNC Automation Components

Aluminum is widely used in automation due to its excellent machinability, light weight, and balance of strength vs. cost.

Aluminum 6061 — The Most Versatile CNC Aluminum

Key Properties

- Tensile Strength: ~290 MPa

- Excellent machinability

- Lightweight

- Good corrosion resistance

- Suitable for anodizing

Typical Applications

- Brackets & mounts

- Sensor housings

- Lightweight frames

- Pneumatic system components

Pros

- Very easy to machine

- Low cost

- Stable performance

- Good weldability

Cons

- Lower strength than 6082

- Not ideal for heavy load applications

Aluminum 6082 — Stronger Structural Performance

Key Properties

- Tensile Strength: ~340 MPa (T6)

- Better corrosion resistance than 6061

- Good extrusion capability

- High stiffness

Typical Applications

- Robot arm structures

- Load-bearing frames

- Conveyor parts

- Automation beams

Pros

- Higher strength than 6061

- Excellent mechanical stability

- Good for high-load automation parts

Cons

- Slightly more difficult to machine

- Cost slightly higher

Stainless Steels for CNC Automation Components

Stainless steel is ideal when parts require strength, durability, chemical resistance, and long lifecycle performance.

Stainless Steel 304 — Standard Industrial Choice

Key Properties

- Excellent corrosion resistance

- Good toughness

- Non-magnetic

- Good high-temperature stability

Typical Applications

- Food-grade automation equipment

- Industrial enclosures

- Chemical-resistant components

Pros

- Affordable

- Corrosion resistant for general environments

- Strong and stable

Cons

- Harder to machine than aluminum

- Not suitable for strong chloride environments

Stainless Steel 316 — Marine & Chemical-Grade

Key Properties

- Molybdenum-containing alloy

- Exceptional chloride corrosion resistance

- High durability

- Excellent chemical resistance

Typical Applications

- Marine automation systems

- Chemical processing stations

- Medical robotics

- High-humidity environments

Pros

- Best corrosion resistance among common steels

- Suitable for harsh or wet conditions

Cons

- More expensive

- Higher tool wear

- Longer machining time

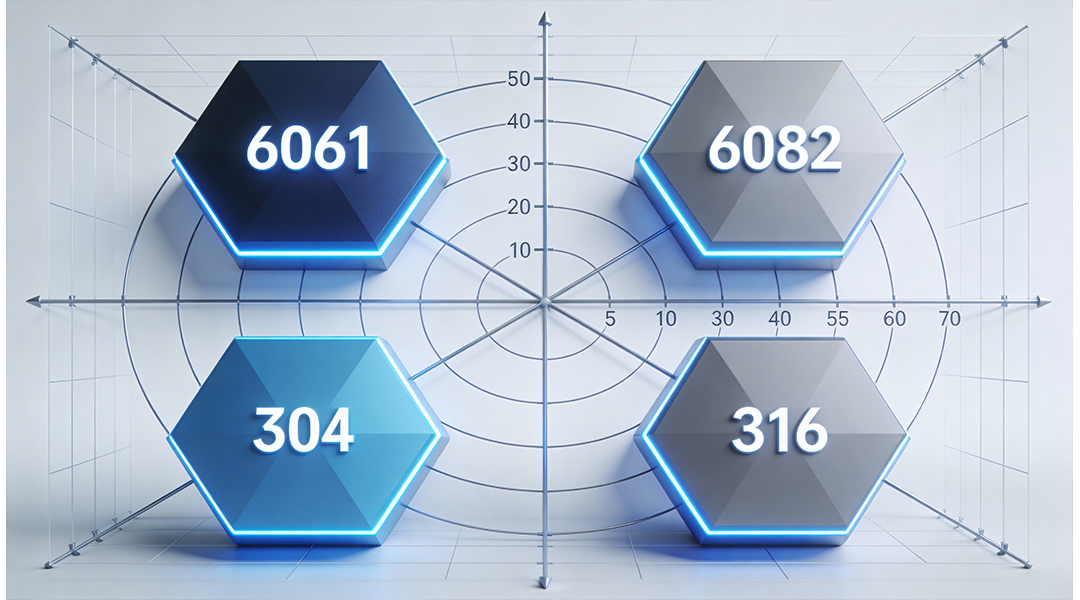

Material Comparison Table

|

Material |

Strength |

Machinability |

Corrosion Resistance |

Cost |

Best For |

|

6061 |

★★★ |

★★★★★ |

★★★★ |

$ |

General automation components |

|

6082 |

★★★★ |

★★★★ |

★★★★ |

$$ |

Load-bearing robotic parts |

|

304 |

★★★★ |

★★★ |

★★★★ |

$$ |

Industrial automation |

|

316 |

★★★★★ |

★★ |

★★★★★ |

$$$ |

Marine/chemical automation |

How to Choose the Right Material for Automation CNC Parts

Based on Strength Requirements

- Light load → 6061

- Medium-to-heavy load → 6082

- High strength + corrosion → 304 / 316

Based on Environment

- Indoor, dry → 6061 / 6082

- Industrial chemicals → 304

- Marine / saline / steam → 316

Based on Cost

- Budget projects → 6061

- Long-term durability → 316

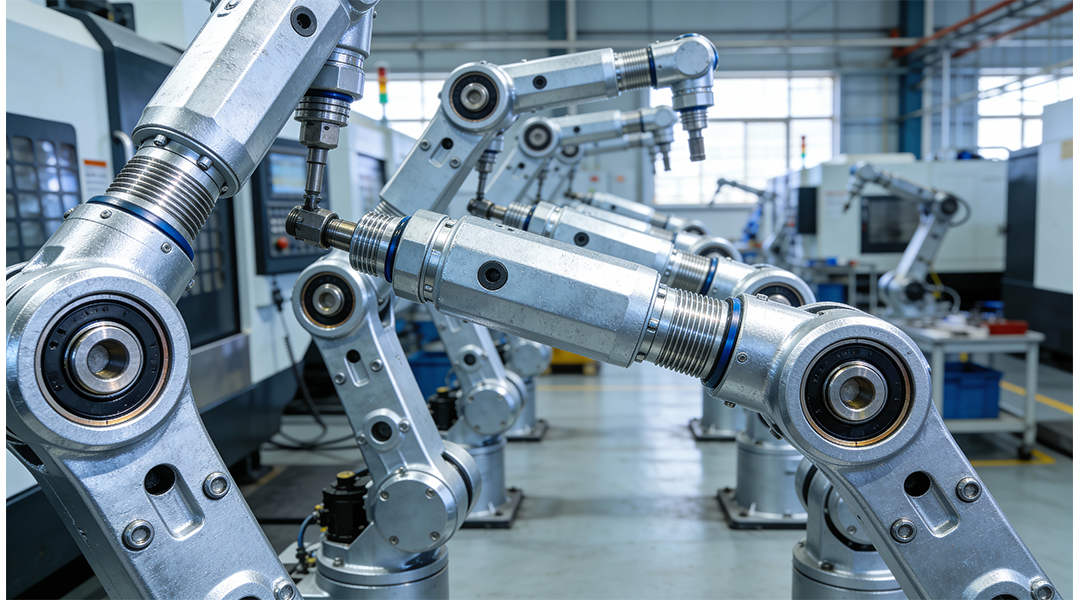

Real Use Case Examples

Case 1 — Robotic Arm Structural Components

Chosen material: 6082

Reason: High stiffness, excellent strength-to-weight ratio.

Case 2 — Food Automation Conveyor

Chosen material: 304

Reason: Cleanability + corrosion resistance

Case 3 — Marine Automation Sensors

Chosen material: 316

Reason: Superior chloride corrosion resistance.

Tips to Reduce CNC Cost with Material Choice

Optimize Geometry for Machinability

Rounded corners, uniform wall thickness, avoid deep pockets.

Match Tolerances to Function

Over-tight tolerances increase machining cost significantly.

Use the Right Alloy for the Right Job

Choosing unnecessary high-grade material wastes cost.

Conclusion

6061, 6082, 304, and 316 are four of the most important CNC materials for automation systems. Each material has unique advantages—and choosing the right one depends on load requirements, environment, machining efficiency, and cost expectations.

A smart material choice significantly improves part durability, performance, and lifecycle value for any automation system.

Post time: Dec-17-2025